Enhanced fishing rod and manufacturing method thereof

A production method and enhanced technology, which is applied to fishing rods, fishing, and other household appliances, can solve the problems of increased operating procedures and production costs, easy sticking of labels, poor elasticity and toughness, etc., to achieve enhanced fish Rod quality, toughness and practical enhancement, the effect of good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

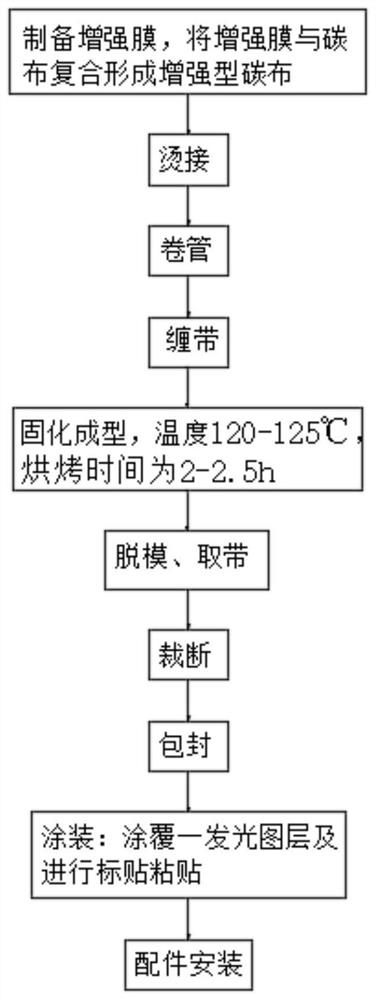

[0029] refer to figure 1 , the present embodiment provides a method for making an enhanced fishing rod, comprising the following steps:

[0030] a. Take the carbon cloth to be used, spread the reinforced film on the carbon cloth, and compound the reinforced film to the surface of the carbon cloth by hot pressing, so that the two are fully bonded together. The pressure is 6-6.5MPa, and the hot-pressing time is 1-2min; the making of the reinforced membrane includes: bisphenol A epoxy resin with a mass fraction of 85-95% and polyethersulfone with a mass fraction of 5-15% Add it into an appropriate amount of organic solvent for mixing, the temperature of the mixture is controlled at 75-80°C, stir until the bisphenol A epoxy resin and polyethersulfone are completely dissolved, then add toner with a mass fraction of 1-8% and mix evenly. Pour the obtained sample into a container, move it to a vacuum oven, and evacuate it at a temperature of 40-50°C until the solvent is completely re...

Embodiment 2

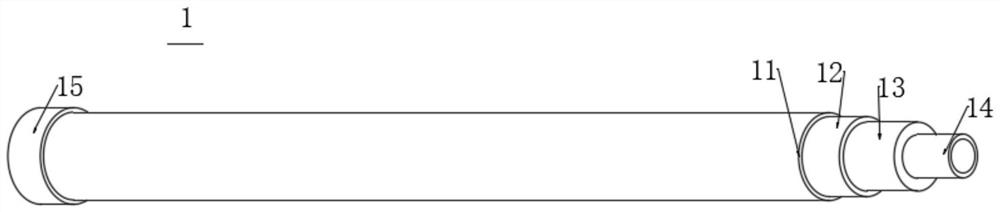

[0044] refer to figure 2 , this embodiment provides an enhanced fishing rod, including a fishing rod tube 1 and accessories (not shown) arranged on the fishing rod tube 1, the fishing rod tube 1 includes a tube body 13, the tube The outer wall of the body 13 is coated with an outer reinforcing film 12, the inner wall of the tube body 13 is covered and pasted with an inner reinforcing film 14, and the two ends of the tube body 13 are provided with a reinforcing film encapsulation 15, and the fishing rod tube 1 The outer periphery is coated with a luminescent coating 11, and the outer enhancement film 12 is provided with a pattern.

[0045] The enhanced fishing rod is provided with an outer reinforced film 12 and an inner reinforced film 14 on the surface of the tube body 13, and reinforced film encapsulation 15 is arranged at both ends, so that the strength, toughness and practicability of the obtained fishing rod are greatly enhanced, and because the reinforced film The weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com