Crack self-filling type electronic connector and processing technology thereof

An electronic connector and filling technology, which is applied in the field of crack self-filling electronic connector and its processing technology, can solve the problems of affecting the signal transmission of the PCB board, affecting the normal use of the circuit, and easy aging of plastics, so as to reduce circuit damage. , Improve filling efficiency, increase the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

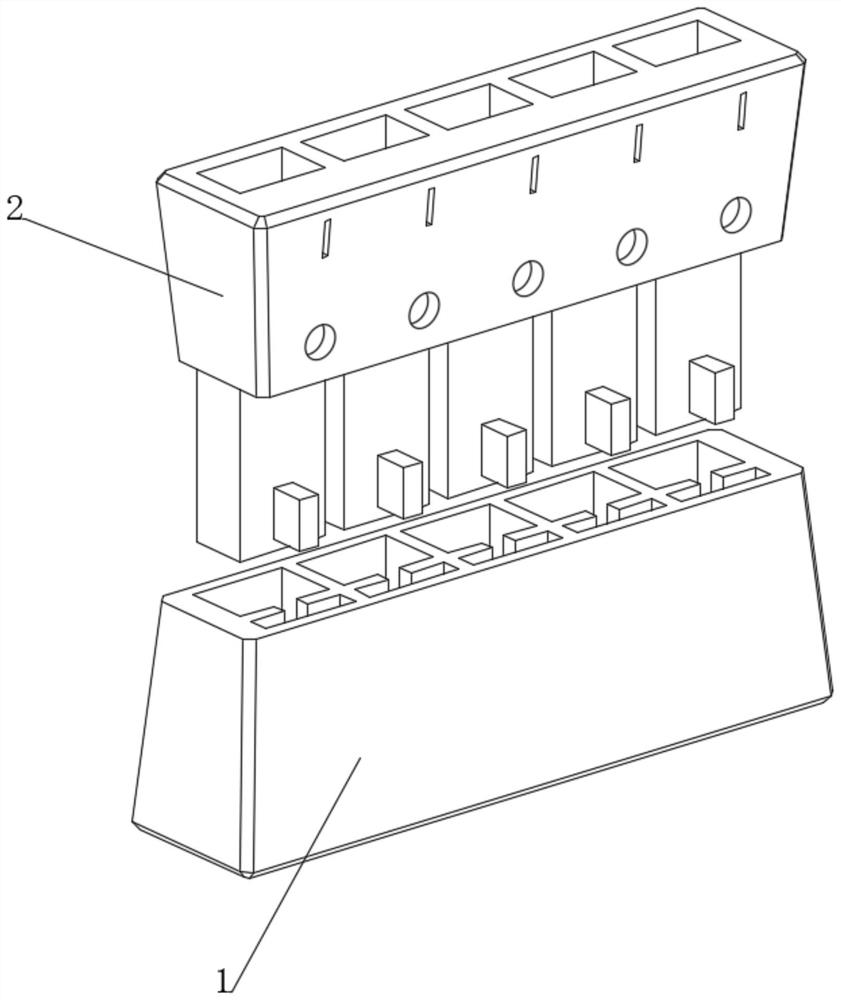

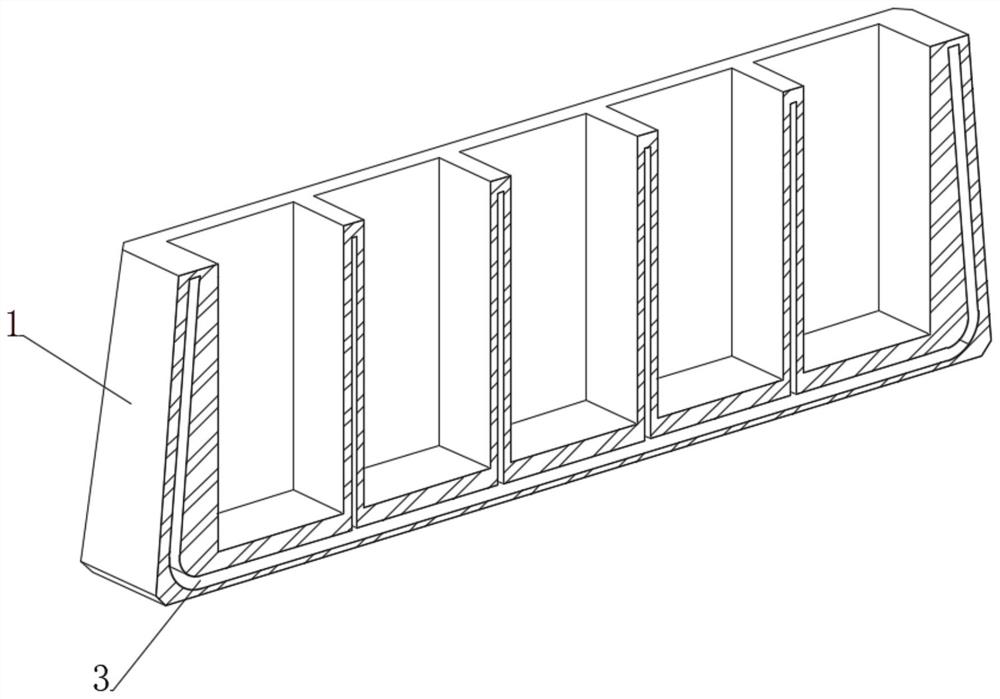

[0055] see Figure 1-12 , a crack self-filling electronic connector, including an electronic connector body, the electronic connector body includes a connector welding slot 1 and a connector crimping pin 2 inserted into the connector welding slot 1, the connector A vacuum repair chamber 3 is provided in the welding slot 1, and a plurality of flexible connecting struts 5 are fixedly connected to the vacuum repair chamber 3, and a plurality of flexible insulating balls 4 are fixedly connected to the flexible connecting struts 5, and the outer ends of the flexible insulating balls 4 A plurality of elastically extending oil-absorbing strips 6 are fixedly connected, and self-decomposing filling balls 7 are connected to the outer ends of the elastically extending oil-absorbing strips 6 . Through the mutual cooperation of the flexible insulating ball 4, the flexible connecting support bar 5, the elastically extending oil-absorbing strip 6 and the self-decomposing filling ball 7, when...

Embodiment 2

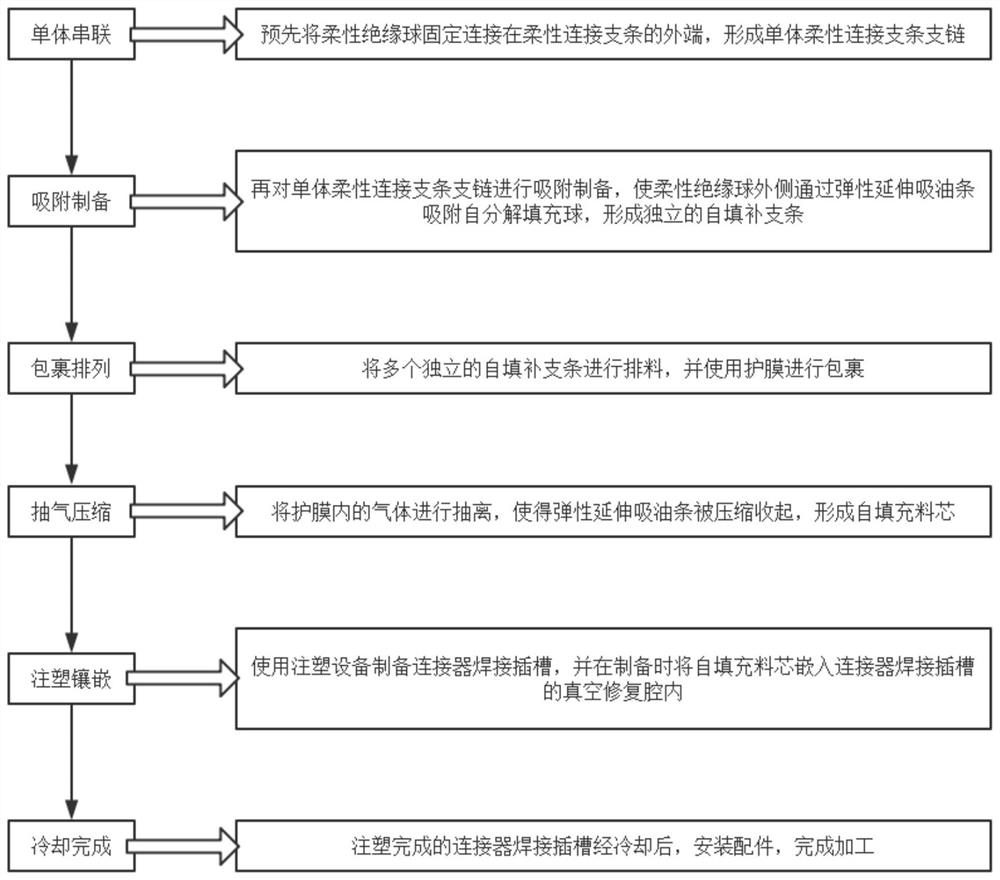

[0065] see Figure 1-12 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: please refer to figure 2 , a process for processing a crack self-filling electronic connector, comprising the steps of:

[0066] S1. Monomer series connection: the flexible insulating ball 4 is fixedly connected to the outer end of the flexible connecting bar 5 in advance to form a single flexible connecting bar 5 branch chain;

[0067] S2. Adsorption preparation: the monomer flexible connection branch 5 is then prepared by adsorption, so that the outer side of the flexible insulating ball 4 is elastically extended by the oil-absorbing strip 6 to absorb and self-decompose the filling ball 7 to form an independent self-filling branch;

[0068] S3. Packing arrangement: m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com