Automatic detection method and device for depth of piston clamp spring groove

An automatic detection device and automatic detection technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of high labor costs, increased manual detection, and manual detection prone to errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

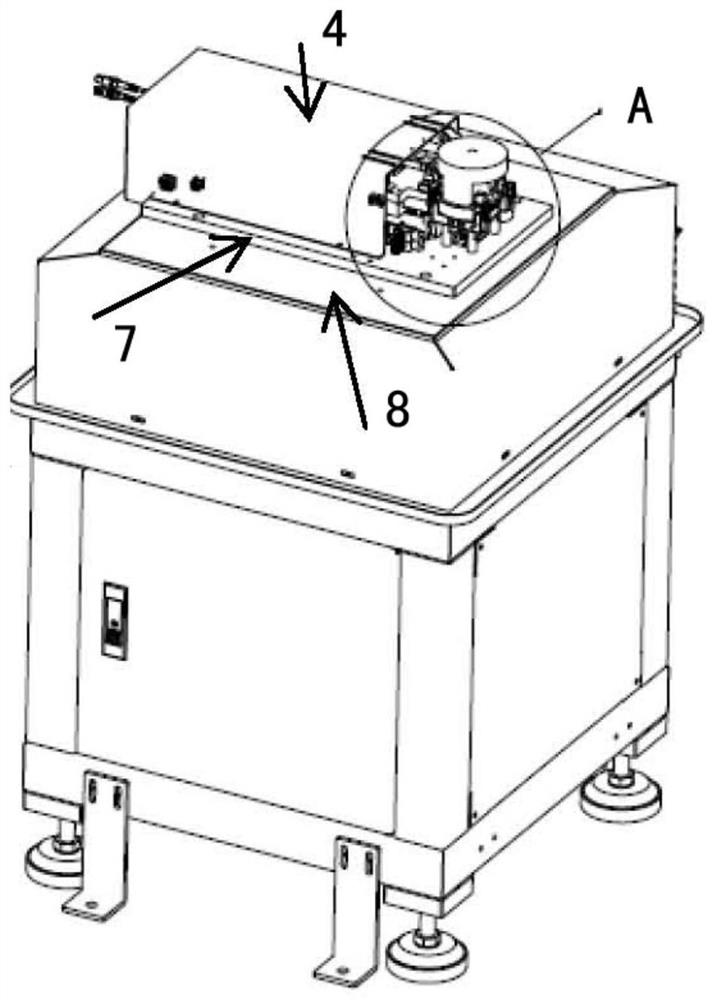

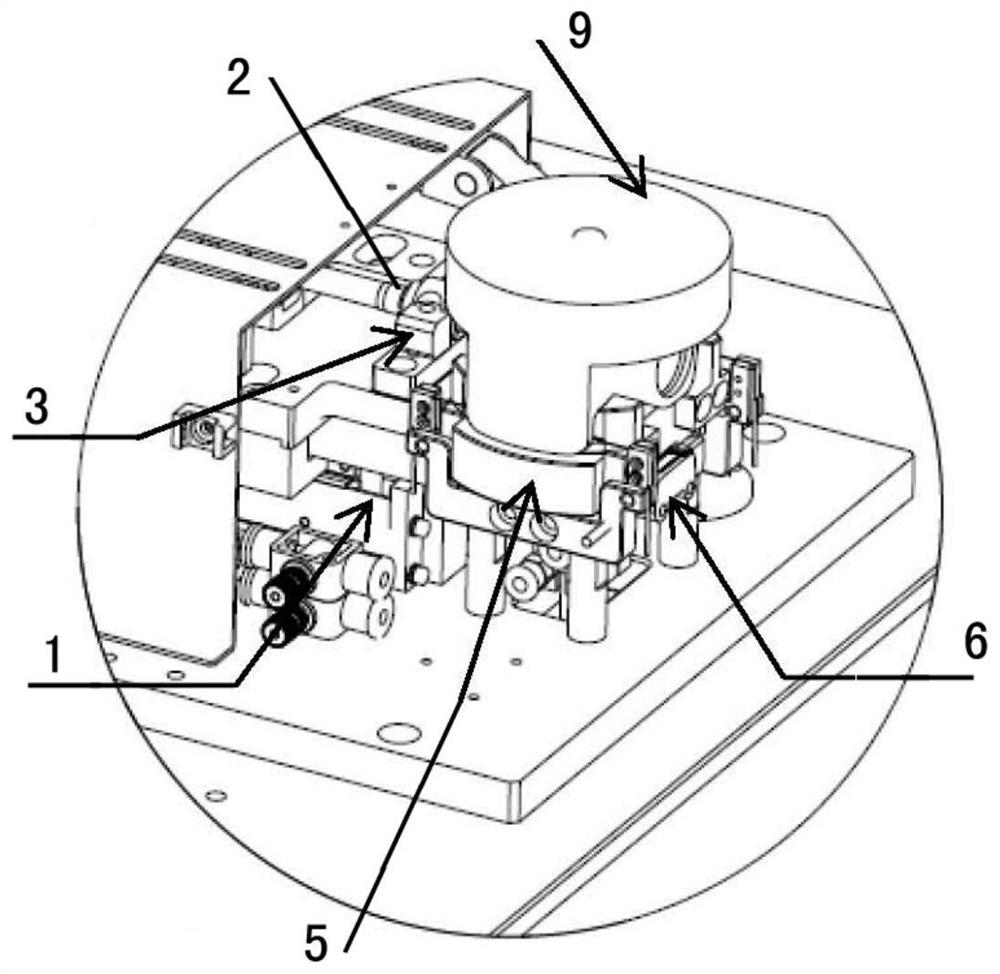

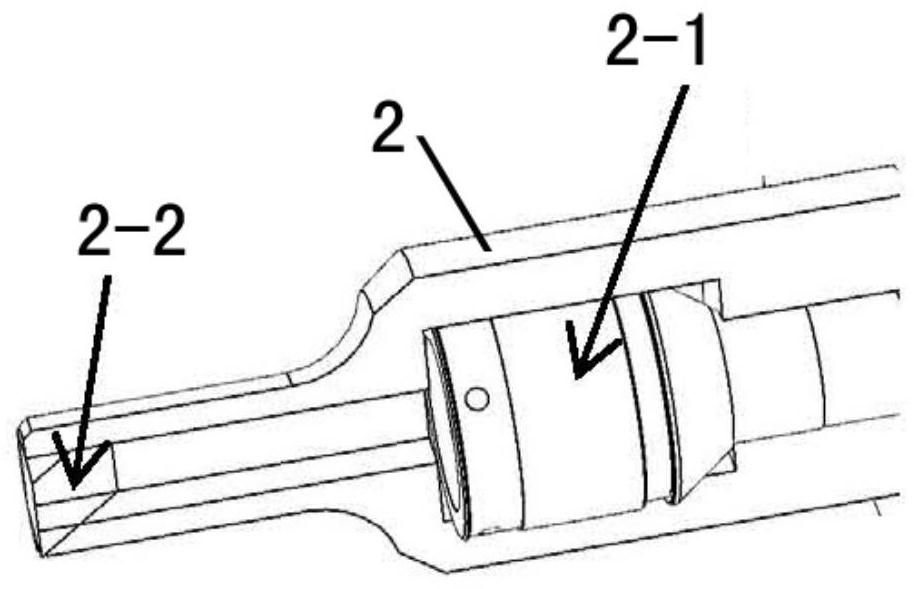

[0035] refer to Figure 1 to Figure 3 The automatic detection device for the depth of the piston circlip groove involved in this embodiment includes a servo motor module 1, a laser detector 2, a laser detection fixture 3, a workpiece fixing fixture 5 and an air detection device 6, the servo motor module 1, Laser detector 2, laser detection fixture 3, workpiece fixing fixture 5 and air detection device 6 are arranged on fixed base 7; It performs blowing and drying; the drive output end of the servo motor module 1 is connected to the laser detection head 2-1 of the laser detector 2 to drive the laser detection head 2-1 to the detection position; the workpiece fixing fixture 5 has a limit fixing structure, To limit and fix the workpiece; the laser detector 2 is fixedly arranged in the laser detection fixture 3, and its laser detection head 2-1 faces the piston circlip groove of the workpiece, emits and receives reverse light to the piston circlip groove, The reflected light rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com