Suction arm

The technology of a suction device and a boom, which is applied in the field of suction arms, can solve problems such as difficult suction, and achieve the effects of high working efficiency and strong adaptability to working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

[0055] The present invention provides a suction arm, which is used to suck the materials accumulated on the ground into the collecting box 29 to play the role of material cleaning, especially during the suction operation, it can follow the terrain and the work efficiency is higher , the working conditions are more adaptable, and can be applied to the terrain around the railway.

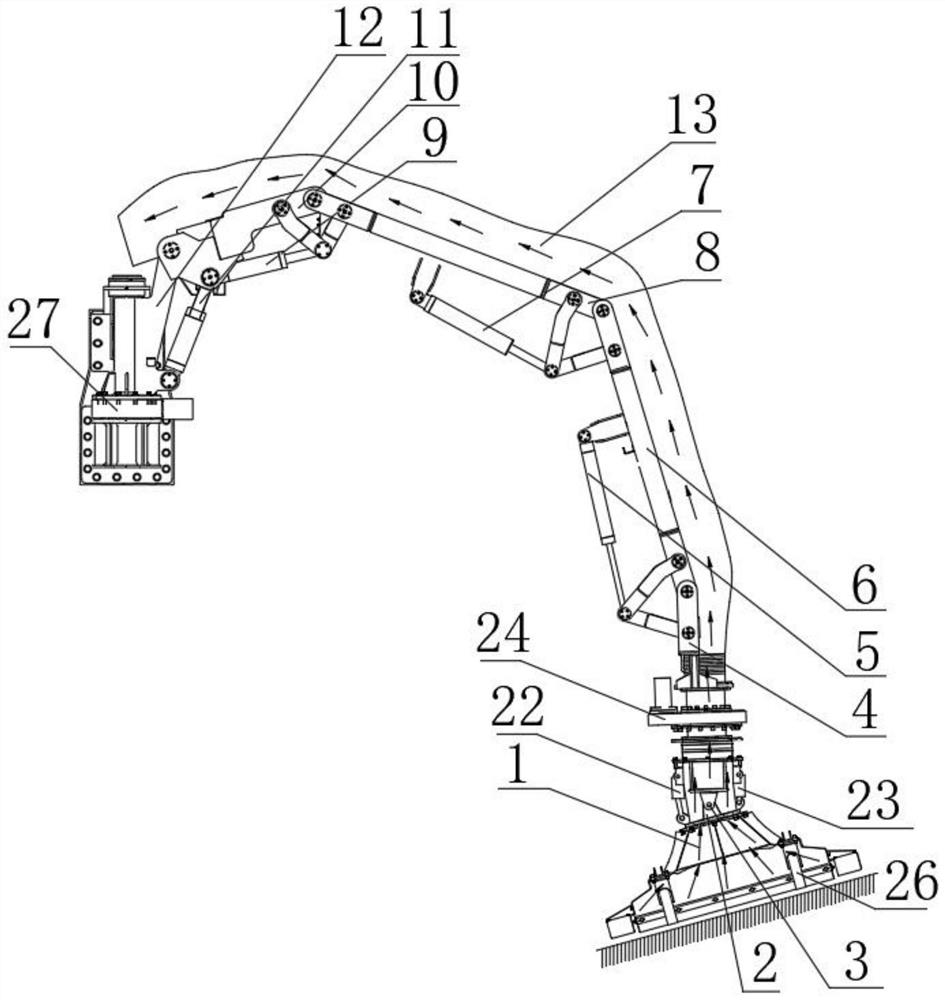

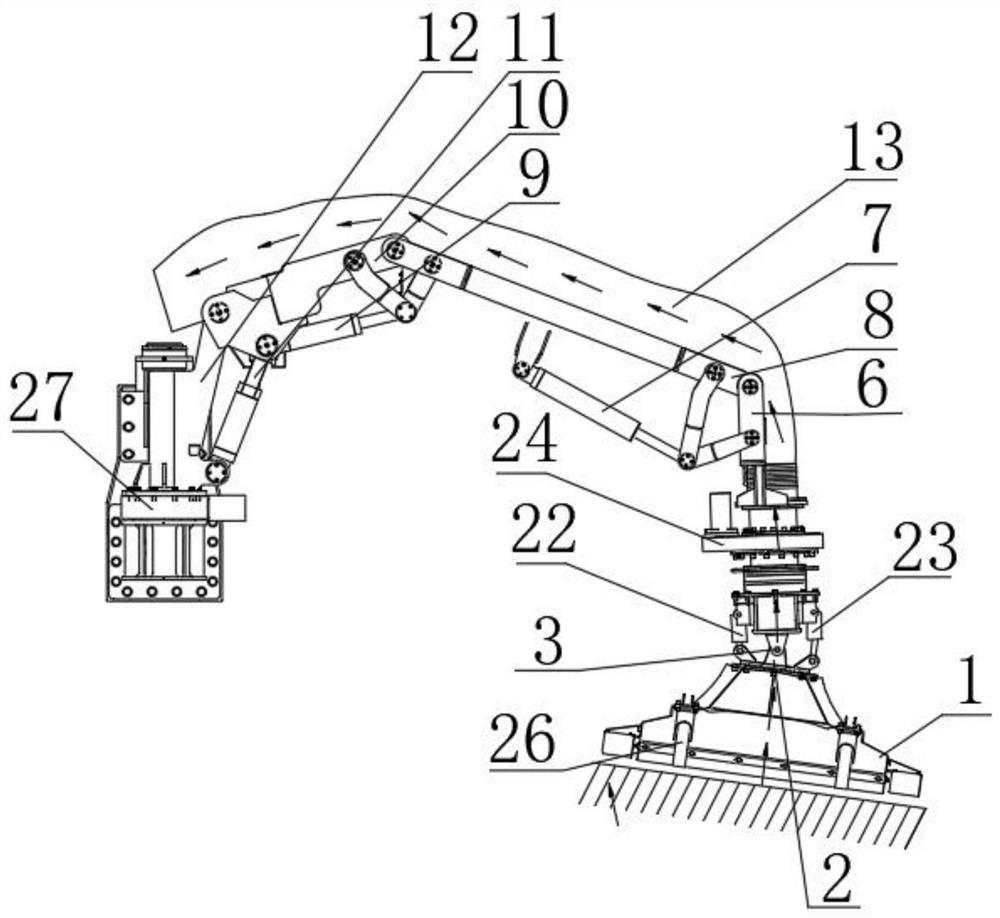

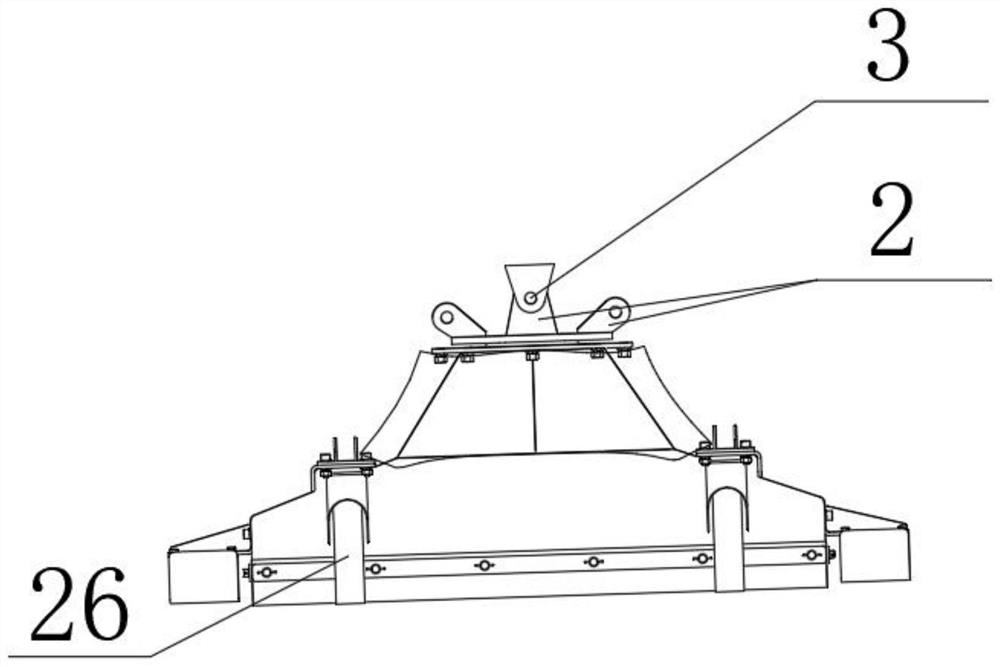

[0056] see figure 1 , in a specific embodiment, the suction arm includes an arm frame, a suction hose 13 and a suction device, the arm frame is used to move the suction device so that the suction device can move to the top of the material to be cleaned ; The suction hose 13 is used to transport the sucked material, specifically the material sucked by the suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com