A kind of preparation method of tapered core fiber with gradually changing core-to-clad ratio and tapered core fiber

A tapered core and core wrap technology, applied in cladding fibers, glass fibers, optical waveguides, etc., can solve the problems of reducing laser output power, thermally induced mode instability, reducing pump light absorption efficiency, etc. Effects of output power, increased absorption, increased thermally induced mode instability threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

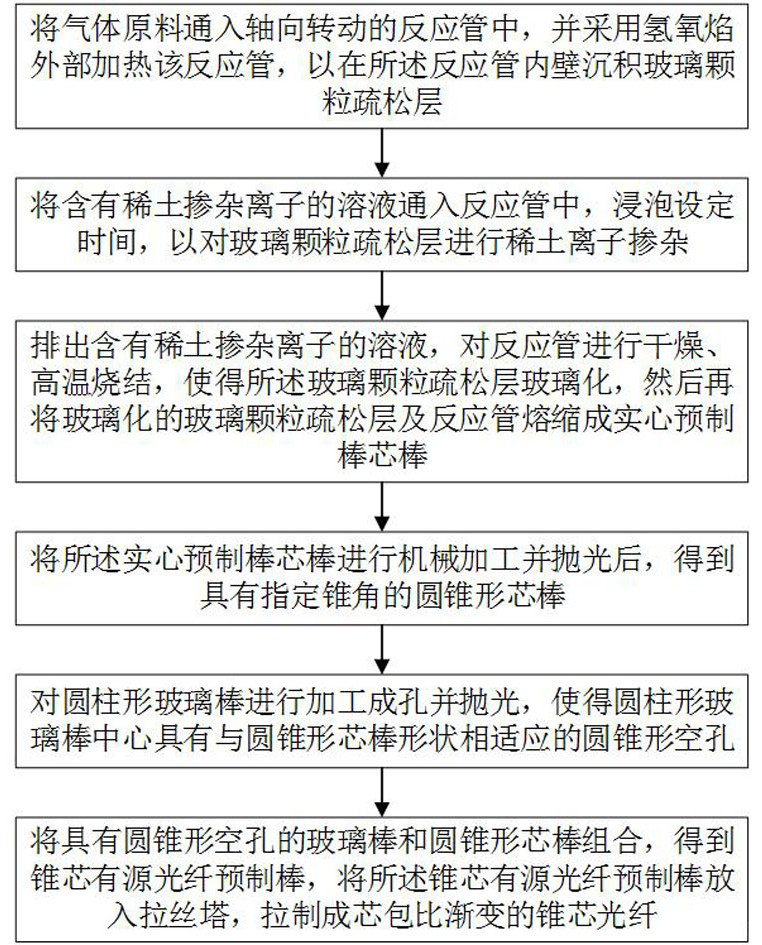

[0054] In this embodiment, a method for designing and manufacturing a cone-core ytterbium-doped optical fiber with a gradually changing core-to-clad ratio, the specific method and steps are as follows:

[0055] Step 1, the SiCl 4 with O 2 Pass into the axially rotating reaction tube together, the hydrogen-oxygen flame is externally heated, and SiO is deposited on the inner wall of the reaction tube 2 A loose layer of glass particles.

[0056] Step 2, 6.0g YbCl 3 ·6H 2 O was dissolved in 500mL deionized water to make a solution, injected into the reaction tube, soaked for 3h, and carried out Yb 3+ Doped.

[0057] Step 3, discharge YbCl 3 ·6H 2 O aqueous solution, drying the reaction tube, sintering at 1650°C at high temperature to achieve vitrification of the loose layer, and then melting and shrinking at 1850°C to form a solid prefabricated core rod.

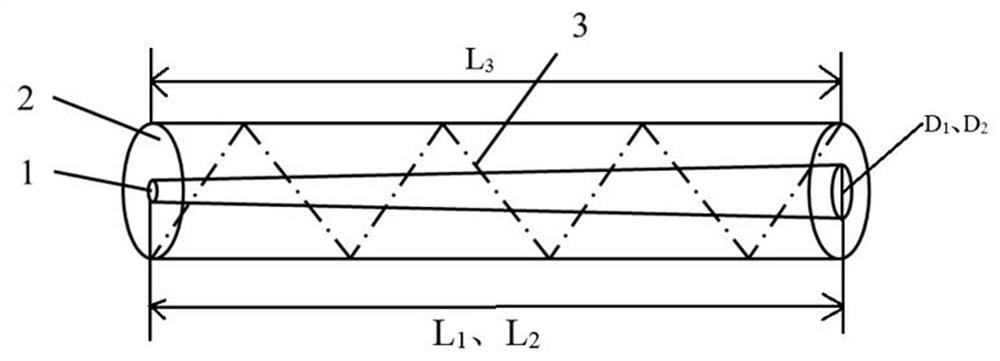

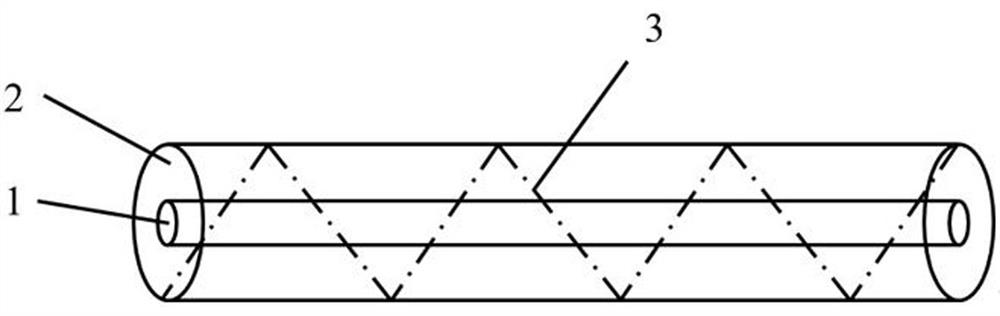

[0058]Step 4, after machining and polishing the solid prefabricated rod mandrel, a conical mandrel is obtained, and th...

Embodiment 2

[0062] Step 1: prepare a quartz reaction tube, clean the quartz reaction tube, install a rotary joint on the inlet section of the quartz reaction tube, install the quartz reaction tube on a deposition lathe, and preheat the quartz reaction tube externally with an oxyhydrogen flame. Quartz reaction tube, during the preheating process, gradually increase the temperature of the quartz reaction tube to 1200°C. After the temperature of the reaction tube is heated to 1750°C, SiCl is introduced into the quartz reaction tube according to the preset flow rate. 4 、GeCl 4 with O 2 , during the repeated rotation of the reaction tube, a loose layer of glass particles with a specified thickness of 1.5 cm is deposited on the inner wall of the reaction tube. The loose layer of glass particles is SiO 2 and GeO 2 .

[0063] Step 2, carry out Nd 3+ 5.2g Nd(NO 3 ) 3 ·6H 2 O was dissolved in 500mL of absolute ethanol to make a solution, injected into the reaction tube, soaked for 2h, and c...

Embodiment 3

[0069] Step 1, the SiCl 4 , POCl 3 with O 2 Pass into the axially rotating reaction tube together, the hydrogen-oxygen flame is externally heated, and SiO is deposited on the inner wall of the reaction tube 2、 P 2 o 5 A loose layer of glass particles.

[0070] Step 2, carry out Er 3+ Doped. 6.2gErCl 3 ·6H 2 O was dissolved in 400mL of absolute ethanol to make a solution, injected into the reaction tube, soaked for 2.5h, and performed Er 3+ Doped.

[0071] Step 3, discharge ErCl 3 ·6H 2 O absolute ethanol solution, drying the reaction tube, sintering at a high temperature of 1350 ° C to achieve vitrification of the loose layer, and then melting and shrinking at 1860 ° C to form a solid prefabricated rod mandrel.

[0072] Step 4, after machining and polishing the solid prefabricated rod mandrel, a conical mandrel is obtained, and the diameter of the end face of the mandrel is D 1 =5cm, the length L of mandrel 1 =200cm.

[0073] Step five, machining the inner wall ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com