Equipment for grinding round bar wood cores

A wood core and equipment technology, applied in the direction of grinding/polishing equipment, metal processing equipment, grinding feed movement, etc., can solve the problems of difficult batch grinding of wood cores, slow grinding speed of wood cores, and low degree of automation. Achieve the effect of saving manual transportation time, beautiful materials and prolonging the application time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

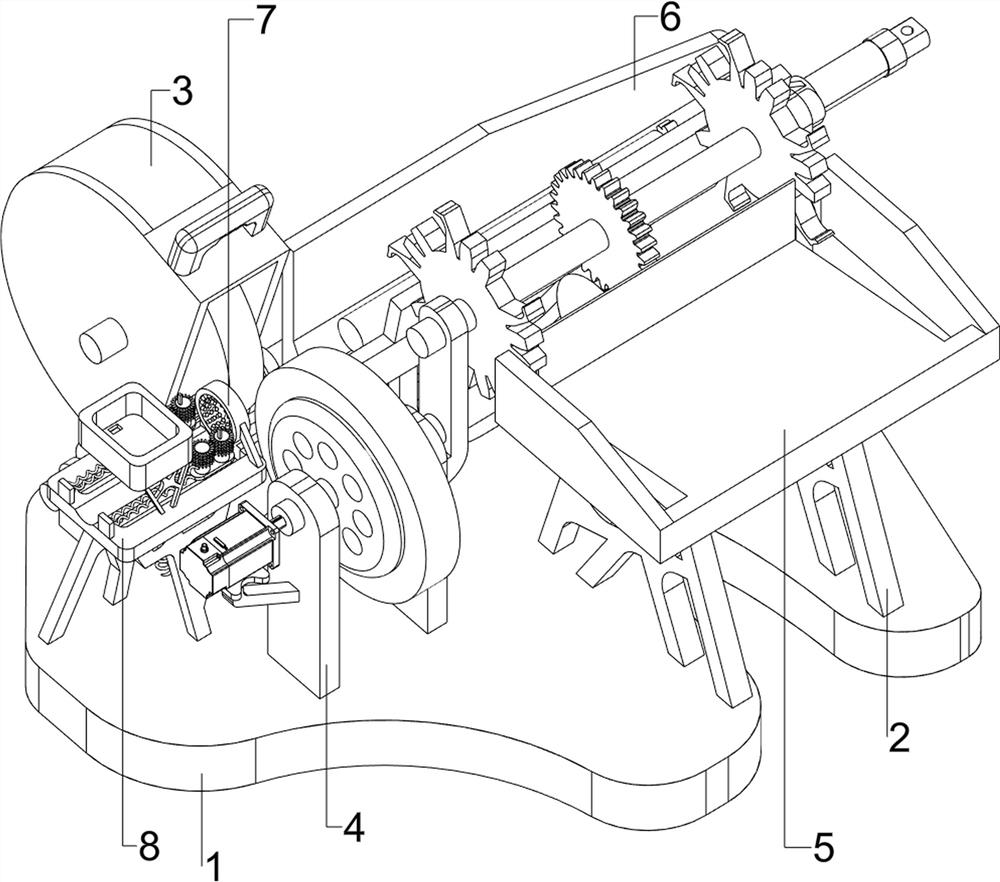

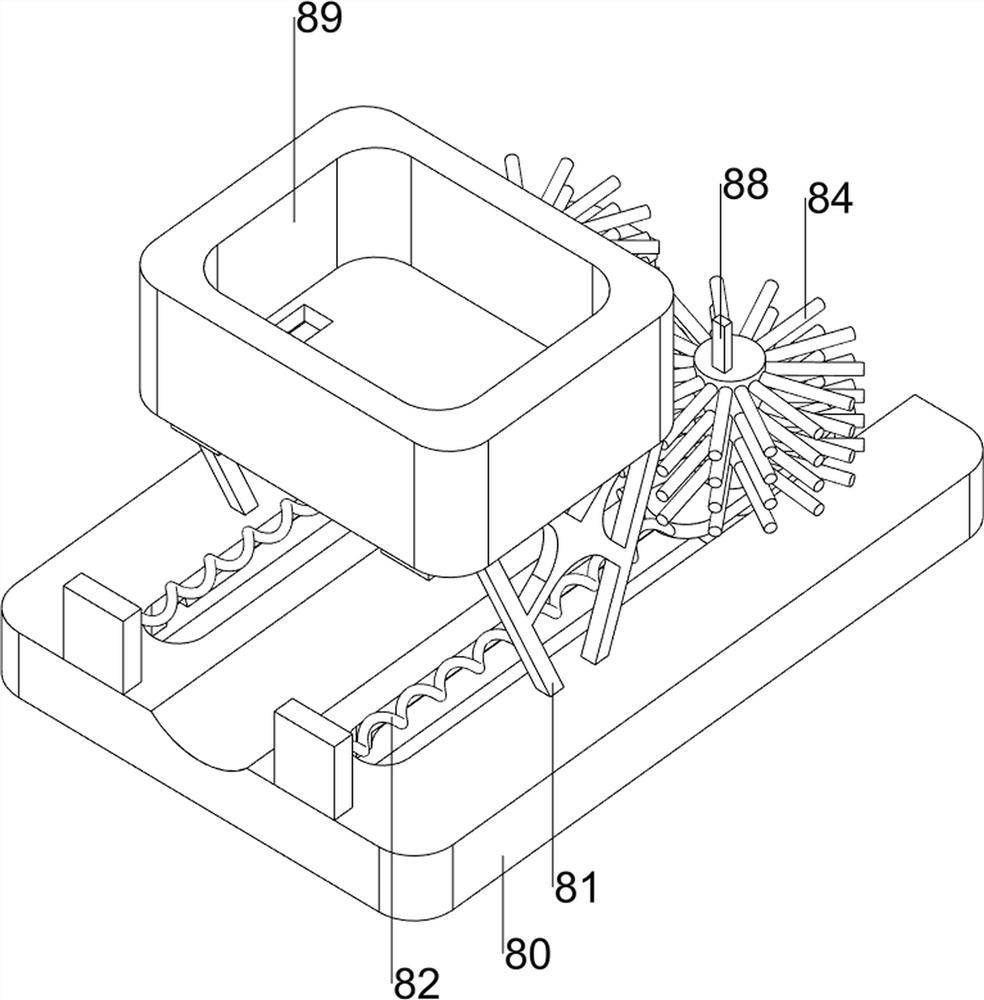

[0061] A kind of grinding equipment for round bar wood core, such as figure 1 As shown, it includes a base plate 1, a first bracket 2, a grinding mechanism 3 and a limit mechanism 4, the left and right sides of the front of the base plate 1 are provided with the first bracket 2, the left rear side of the base plate 1 is provided with a grinding mechanism 3, and the base plate 1 The left side is provided with limit mechanism 4.

[0062] When people need to polish and wax the material, people manually hold the material, then start the grinding mechanism 3 and the limiting mechanism 4, and people contact the material with the grinding mechanism 3 to perform polishing operations on the material, while the limiting mechanism 4 controls the material. Play the role of a certain limit, to prevent uncontrollable materials in the grinding process, after the end of grinding, people can close the grinding mechanism 3 and the limit mechanism 4.

Embodiment 2

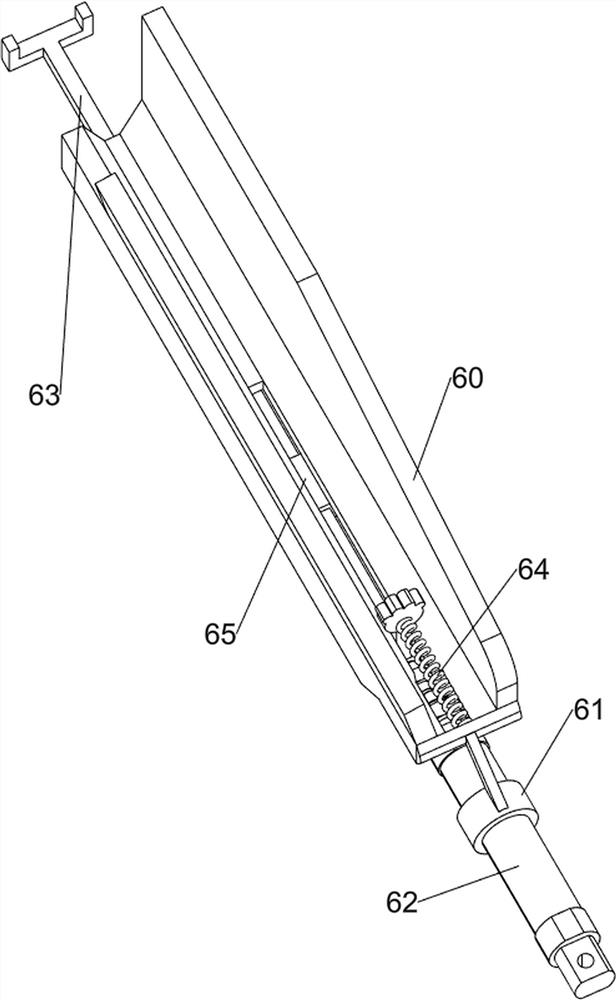

[0064] On the basis of Example 1, such as Figure 2 to Figure 8 As shown, the grinding mechanism 3 includes a first bearing seat 30, a first rotating shaft 31, a crank 32, a first spring 33 and a grinder 34, and the left and right sides of the left rear part of the bottom plate 1 are provided with the first bearing seat 30, the first A first rotating shaft 31 is rotatably connected between the bearing blocks 30, cranks 32 are arranged on the left and right sides of the first rotating shaft 31, a first spring 33 is connected between the crank 32 and the bottom plate 1, and a grinding wheel is provided in the middle of the first rotating shaft 31. device 34.

[0065] When people need to polish and wax the material, people manually hold the material, fit the material with the grinder 34, then start the grinder 34, manually rotate the grinder 34 downward, and the grinder 34 drives the first rotating shaft 31 and the crank 32 rotates, the first spring 33 contracts and moves, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com