Magnetic solid-phase extraction agent as well as preparation method, application and application method thereof

An extraction agent and magnetic solid technology, applied in the field of magnetic solid phase extraction agent and its preparation, can solve the problems such as difficult recovery of molybdenum ions, achieve fast adsorption-desorption kinetics, reduce processing time, and strong magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of magnetic solid phase extraction agent is provided in the embodiment of the present invention, comprises Fe in the magnetic solid phase extraction agent 3 o 4 @SiO 2 @GMA-P magnetic nanoparticles, the Fe 3 o 4 @SiO 2 The chemical structural formula of @GMA-P magnetic nanoparticles is shown in Formula 1.

[0040]

[0041] Wherein, R in Formula 1 is a magnetic ball, and the magnetic ball uses iron ferric oxide nanoparticles as a magnetic core, and uses silicon dioxide as a shell to cover the magnetic core. x, y, and n in Formula 1 are integers greater than or equal to 0 and less than 100.

[0042] As shown in Formula 1, a large number of phosphate groups and hydroxyl groups are connected to the surface of the magnetic ball, and the phosphate groups and the hydroxyl groups can effectively enhance the selection of molybdenum ions through coordination, electrostatic adsorption, etc. , improve the adsorption rate of molybdenum ions.

[0043] The Fe 3 o 4 @S...

Embodiment 2

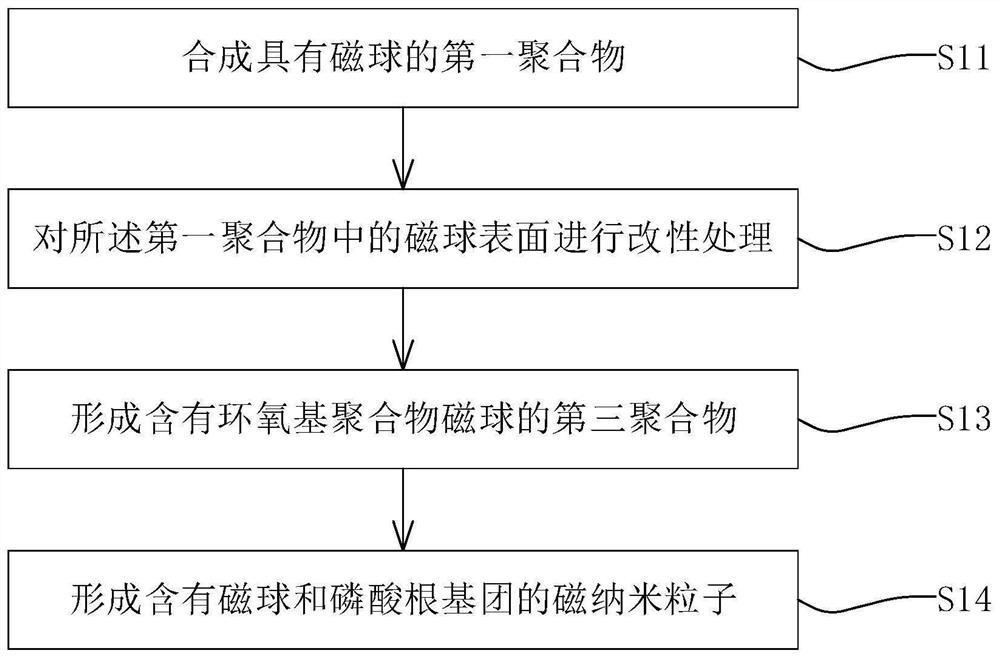

[0080] The embodiment of the present invention also provides a preparation method of magnetic solid phase extraction agent, in order to prepare as described in embodiment 1 containing Fe 3 o 4 @SiO 2 @GMA-P magnetic solid phase extraction agent for magnetic nanoparticles. The flow process of the preparation method of described magnetic solid-phase extraction agent is as follows figure 1 As shown, it includes the following specific steps:

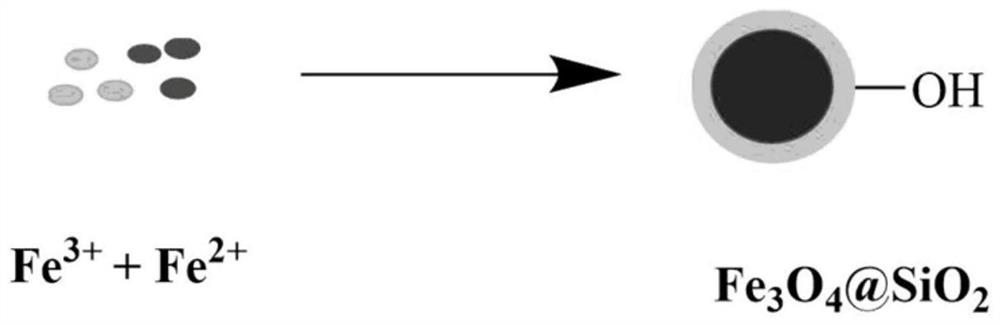

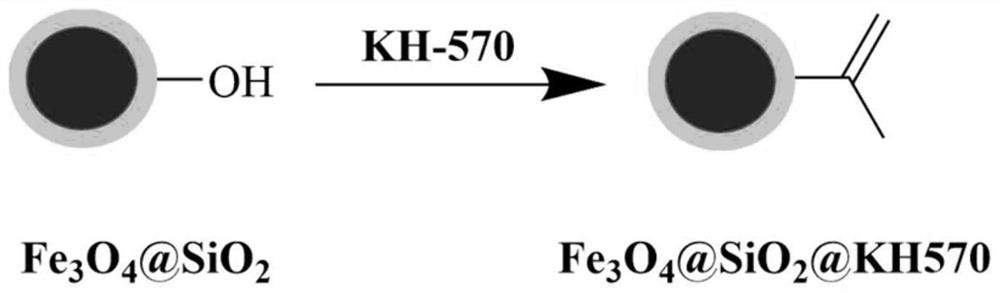

[0081] Step S11) as figure 2 As shown, the first polymer with magnetic spheres was synthesized:

[0082] 11.68g with iron ions (Fe 3+ ) of the first compound and 4.3g with ferrous ions (Fe 2+ ) The second compound was dissolved in 200mL high-purity water to obtain the first mixed solution. Under nitrogen protection, stir and heat the first mixed solution to 85°C, and add 30% ammonia monohydrate (NH 3 ·H 2 O) until the first mixed solution appears black, after reacting for 0.5 hours, the first mixture is obtained, and the first mixt...

Embodiment 3

[0095] The embodiment of the present invention provides a kind of application method of magnetic solid-phase extraction agent as described in embodiment 1, and described magnetic solid-phase extraction agent is used for the reclaiming of molybdenum ion in waste water, preferably in the present embodiment embodiment The magnetic solid-phase extraction agent described in 1 is used for the recovery of the molybdenum ion in the cupric acid waste water in the factory.

[0096] The technological process of molybdenum ion in the cupric acid waste water of described magnetic solid-phase extractant extraction factory is as follows Image 6 Shown, the basic structure of the recovery system of molybdenum ion in the cupric acid waste water of described magnetic solid phase extractant extraction plant is as Figure 7 shown. combine Image 6 and Figure 7 , the recovery method of described molybdenum ion comprises the following steps:

[0097] Step S21) adsorption of molybdenum ions in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com