Liquid injection port detection mechanism with rotating structure for automatic production of lithium battery

A detection mechanism and rotating structure technology, applied in structural parts, battery pack parts, circuits, etc., can solve the problems of inability to detect lithium battery injection ports, difficulty in ensuring detection accuracy, and no rotating structure, and improve friction. power, improve efficiency, and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

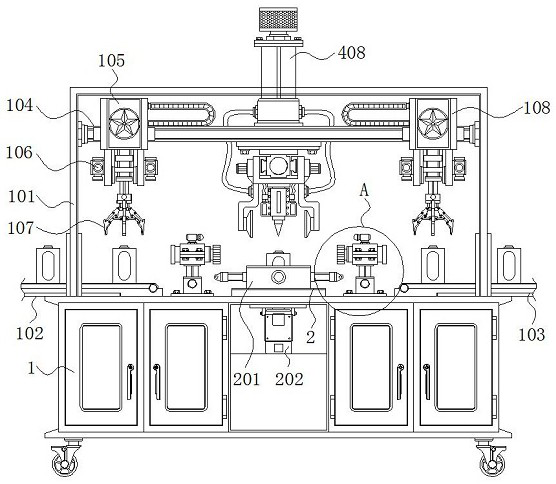

[0046] see figure 1, a liquid injection port detection mechanism with a rotating structure for automatic production of lithium batteries, comprising: a main frame 1; Conveyor belt 102; Unloading conveyor belt 103, which is arranged on the right side of the placement frame 101, and the unloading conveyor belt 103 is distributed in parallel with the placement frame 101, and the upper end of the placement frame 101 is provided with a placement rail 104; The belt 102 and the unloading conveyor belt 103 are distributed symmetrically along the vertical central axis of the placement frame 101, and the placement cross rail 104 is distributed in parallel with the placement frame 101. Through the feeding conveyor belt 102 and the unloading conveyor belt 103, the first The setting of the moving assembly 105 and the second moving assembly 108 realizes the automatic loading and unloading effect of the detection mechanism. The feeding conveyor belt 102 transports the undetected lithium batt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com