Hand wheel rotating mechanism and electronic endoscope bending part fatigue testing device

A technology of rotating mechanism and handwheel, which is applied in the field of medical equipment, can solve the problems of inability to guarantee the test of the bending part of the head end, high labor intensity, and low test efficiency, so as to improve production test efficiency, meet the bending angle, and reduce manual work The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

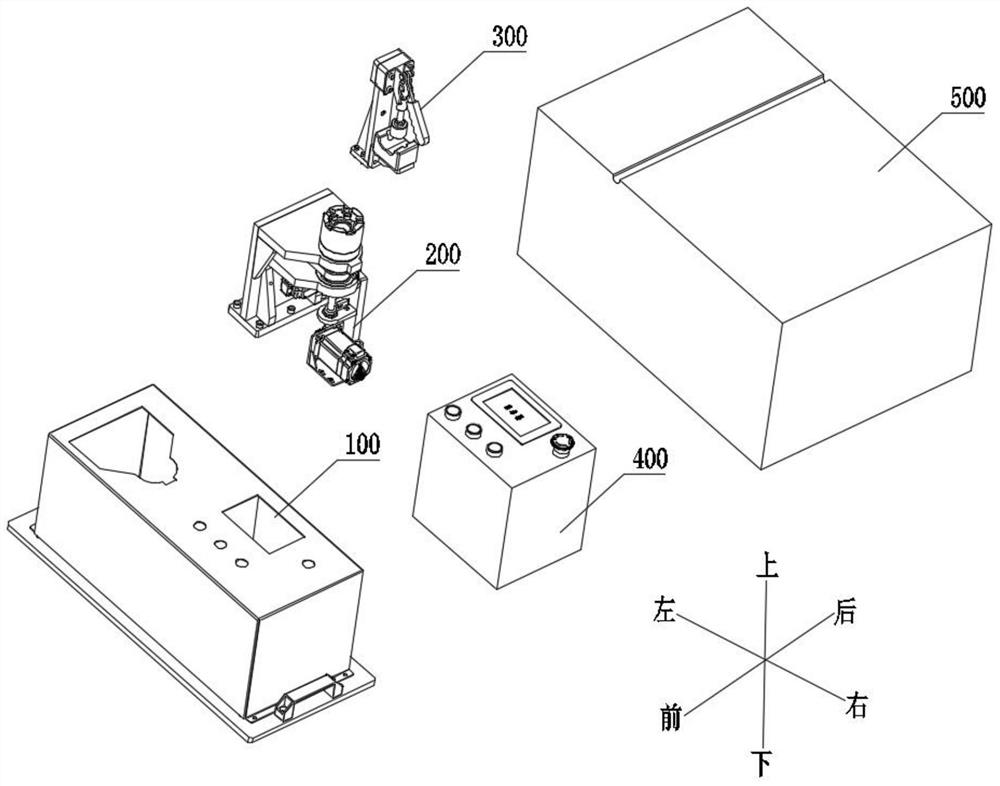

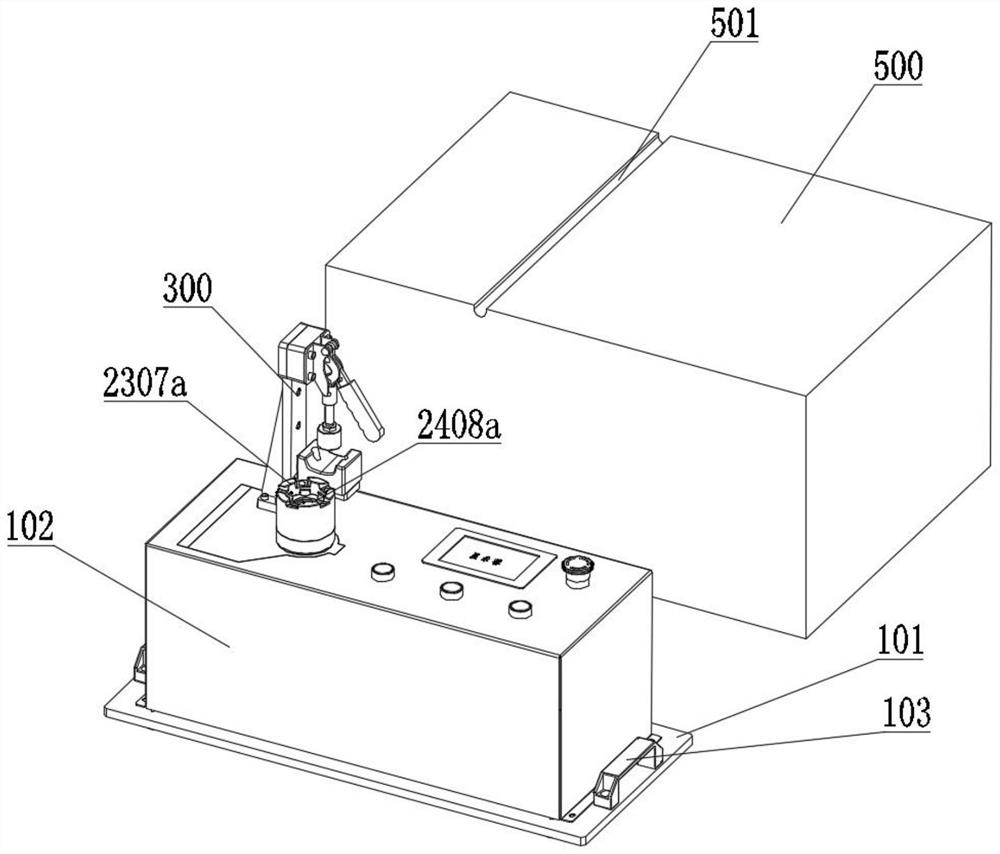

[0041] Such as Figure 1 to Figure 2 As shown, an electronic endoscope bending part fatigue testing device includes a handwheel rotating mechanism 200 and an operating part pressing mechanism 300, and an insertion part support block is provided on the opposite side of the handwheel rotating mechanism 200 and the operating part pressing mechanism 300 500;

[0042] The upper end of the handwheel rotating mechanism 200 is provided with upper and lower handwheel fixing grooves 2307a and left and right handwheel fixing grooves 2408a which can rotate respectively;

[0043] The operating part pressing mechanism 300 is provided with an operating part installation fixing groove 307a;

[0044] The insertion portion supporting block 500 is provided with an insertion portion installation groove 501 .

[0045] Such as Figure 4 to Figure 8 As shown, the handwheel rotating mechanism 200 includes an upper and lower handwheel motor module 2300 and a left and right handwheel motor module 240...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com