Reflective heat-insulation primer-topcoat exterior wall coating and preparation method thereof

A technology for exterior wall paint and bottom surface, applied in the field of paint, can solve the problems of time-consuming and expensive, lack of energy saving and emission reduction, and achieve the effect of reducing construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method for preparing a reflective and heat-insulating bottom-surface-integrated exterior wall coating, comprising the following steps:

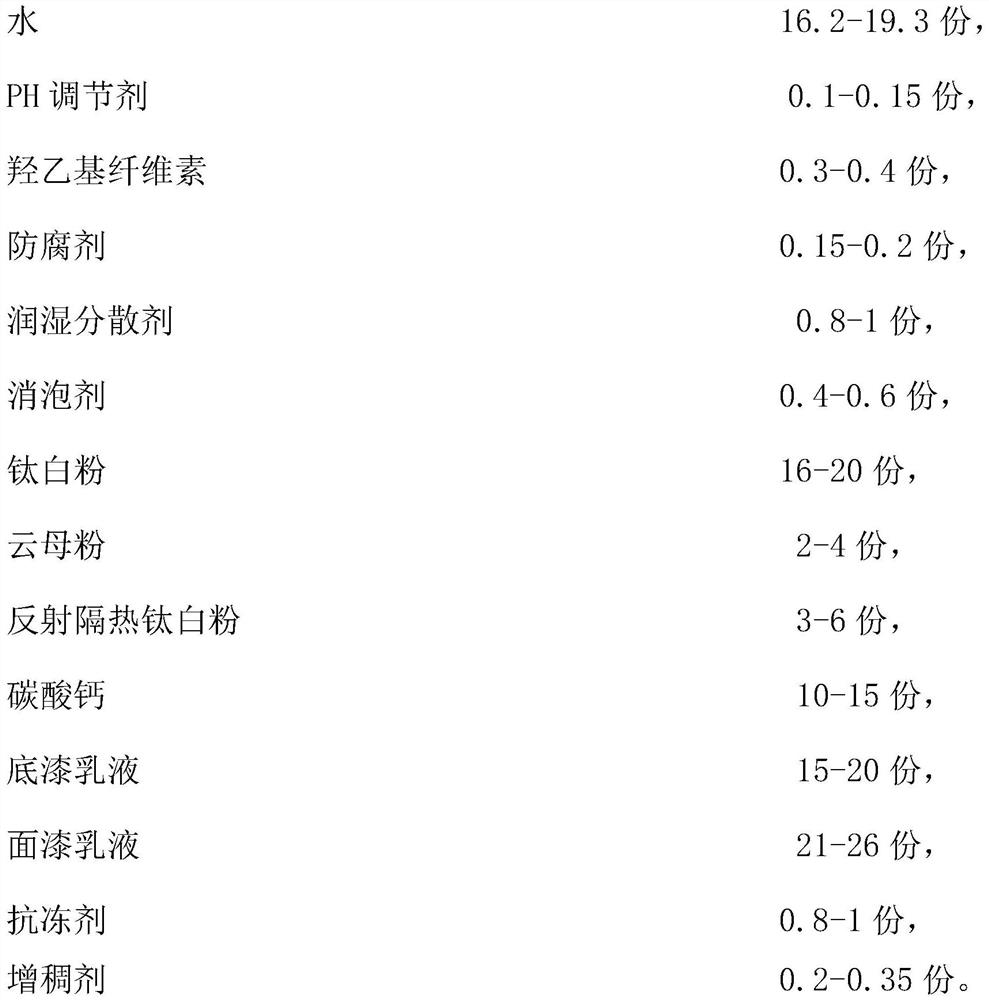

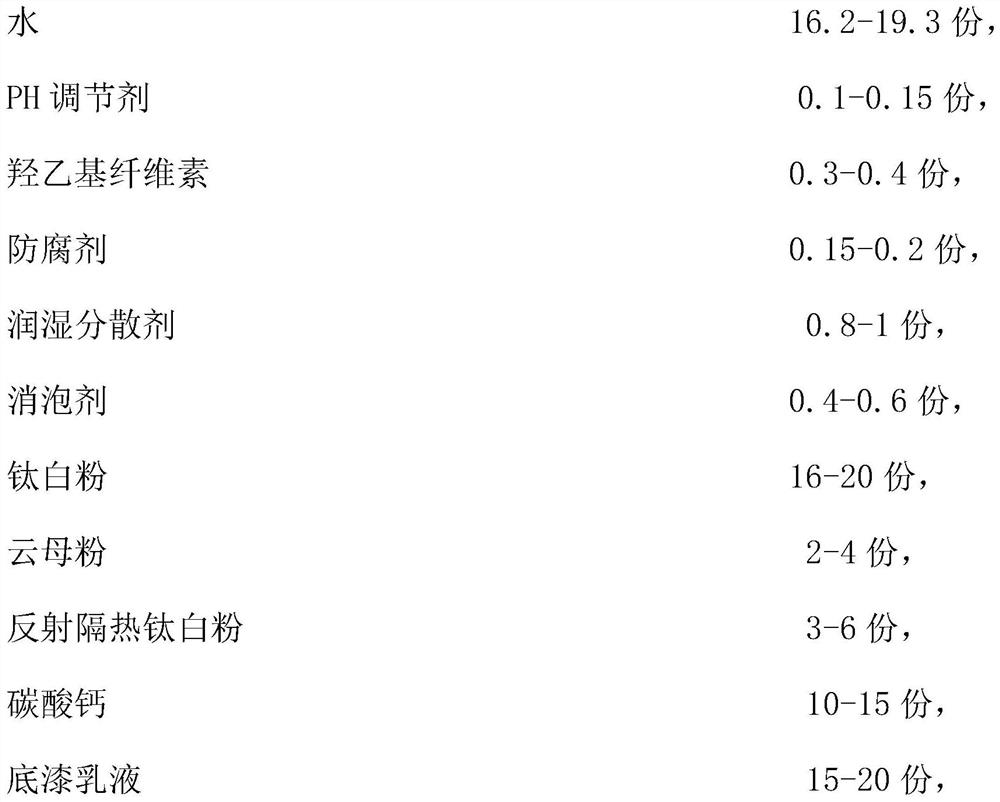

[0036] Step S1, add 16.2-19.3 parts of water into the dispersion tank, add 0.1-0.15 parts of PH regulator, 0.3-0.4 parts of hydroxyethyl cellulose in turn, control the speed of the dispersion tank at 400-450r / min, and continue to disperse for 7-10min ;

[0037] Step S2, slowly add 0.15-0.2 parts of preservative, 0.8-1 part of wetting and dispersing agent, 0.4-0.6 parts of defoamer, adjust the speed of the dispersion cylinder to 350-450r / min, and continue to disperse for 4-8 minutes;

[0038] Step S3, add 16-20 parts of titanium dioxide, 2-4 parts of mica powder, 3-6 parts of reflective heat-insulating titanium dioxide, 10-15 parts of heavy calcium carbonate in sequence, adjust the speed of the dispersion cylinder to 1200-1500r / min, and continue Disperse for 15-20min;

[0039] Step S4, keep the rotation speed of the dispersing cylin...

Embodiment 1

[0056] A reflective and heat-insulating bottom-surface-integrated exterior wall coating, its specific raw materials and weight ratio are as follows:

[0057]

[0058] Craftsmanship:

[0059] (1) Add 16.2 parts of water into the dispersion tank, add 0.1 part of pH regulator and 0.3 part of hydroxyethyl cellulose in sequence, and control the rotation speed at 400r / min for 7 minutes;

[0060] (2) Slowly add 0.2 parts of preservatives, 0.8 parts of wetting and dispersing agents, and 0.4 parts of defoamers, adjust the speed to 350r / min, and continue to disperse for 4 minutes;

[0061](3) Add 20 parts of titanium dioxide, 3 parts of reflective heat-insulating titanium dioxide, 2 parts of mica powder, and 15 parts of calcium carbonate in sequence, adjust the speed to 1200r / min, and continue to disperse for 15 minutes;

[0062] (4) Keep the rotation speed at 500r / min, add 15 parts of primer emulsion and 26 parts of topcoat emulsion in sequence, and continue to disperse for 3 minut...

Embodiment 2

[0065] A reflective and heat-insulating bottom-surface-integrated exterior wall coating, its specific raw materials and weight ratio are as follows:

[0066]

[0067]

[0068] Craftsmanship:

[0069] (1) Add 17.65 parts of water into the dispersion tank, add 0.15 parts of pH regulator and 0.35 parts of hydroxyethyl cellulose in sequence, and control the rotation speed at 450r / min to continue dispersing for 10 minutes;

[0070] (2) Slowly add 0.15 parts of preservatives, 0.9 parts of wetting and dispersing agents, and 0.5 parts of defoamers, adjust the speed to 450r / min, and continue to disperse for 8 minutes;

[0071] (3) Add 18 parts of titanium dioxide, 4 parts of reflective heat-insulating titanium dioxide, 3 parts of mica powder, and 13 parts of calcium carbonate in sequence, adjust the speed to 1500r / min, and continue to disperse for 20 minutes;

[0072] (4) Keep the rotating speed of 650r / min, add 17 parts of primer emulsion and 24 parts of topcoat emulsion in seq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com