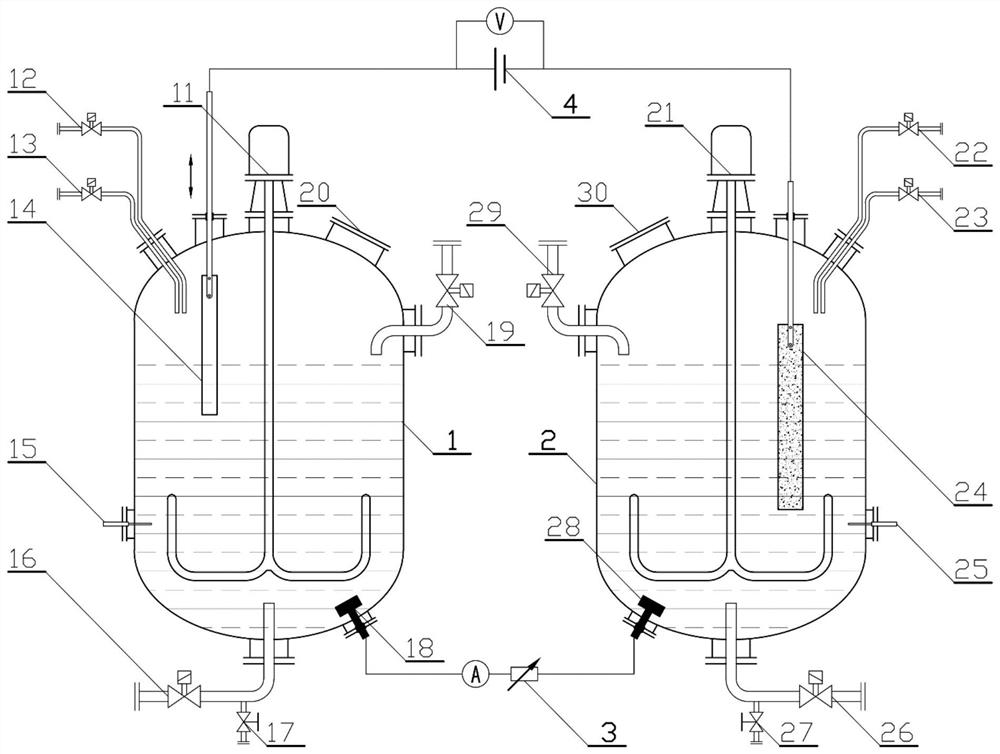

Process and equipment based on electric persulfate activation technology

A technology for activating persulfate and technology, which is applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment equipment, etc. Improve activation effect, reduce activation cost, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0042] Implementation Case 1 Step 1. Take the soil from the contaminated site of a steel factory site. See the 01 sample in Table 1 for the types and concentrations of pollutants. Accurately weigh 3 soil samples, each 300g, numbered 01, 1A, 1B, of which 01 is a blank sample.

[0043] Step 2. Under laboratory conditions, the thickness of the anode is 2mm, and the surface size is 150×20mm 2 sheet of iron. The thickness of the cathode material is 5mm, and the surface size is 150×20mm 2 activated carbon fiber blanket. The power supply between the anode and the cathode is an adjustable phase-shifted full-bridge DC power supply, and the maximum output voltage is 36V. The inert electrode at the bottom is a graphite rod of Φ10mm, connected and connected in series with a 0.1-9999.9Ω high-precision variable resistor with a minimum step value of 0.1Ω.

[0044] Step 3, adding concentration of 20% Na in the anode and cathode beakers respectively 2 S 2 o 8 The solution was 200ml and ...

Embodiment example 2

[0051] Step 1. Take the polluted groundwater from the polluted site of a coal gas plant ruins. See the sample 02 in Table 2 for the types and concentrations of pollutants. Accurately measure 5 water samples, each 200ml, numbered 02, 22A, 22B, 33A, 33B, of which 02 is a blank sample.

[0052] Steps 2 and 3 are the same as those in Case 1.

[0053] Step 4. After energizing for 10 minutes, take 50ml of activated Na from the anode beaker without power on. 2 S 2 o 8 Add the solution into 22A and stir evenly, let it stand, take 50ml activated Na from the cathode beaker 2 S 2 o 8 The solution was added to 22B and stirred evenly, and allowed to stand. At this time, it is also seen that there are a large number of bubbles in the sample, indicating that the reaction is relatively violent.

[0054] After step 5 and 150 minutes, samples 22A and 22B were taken for inspection respectively, and the experimental data are shown in Table 2.

[0055] Table 2 Experimental data (μg / L)

[...

Embodiment example 3

[0058] On the basis of the completion of the implementation case 2, cut off the power for 5 minutes, and take 50ml of activated Na from the anode beaker 2 S 2 o 8 Add the solution into 33A and stir evenly, let it stand, take 50ml activated Na from the cathode beaker 2 S 2 o 8 The solution was added to 33B and stirred evenly, and allowed to stand. At this time, it is also seen that there are bubbles in the sample, but it is not as violent as in Example 2, indicating that after a period of time, the bubbles in the medicament A part may be lost, the experimental data are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com