Box locking structure of packaging box and preparation process thereof

A preparation process and packaging box technology, which is applied in the field of lock box structure and its preparation process, and can solve the problems of reduced use range of paper mold box body, inability to carry paper mold box body, insufficient strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

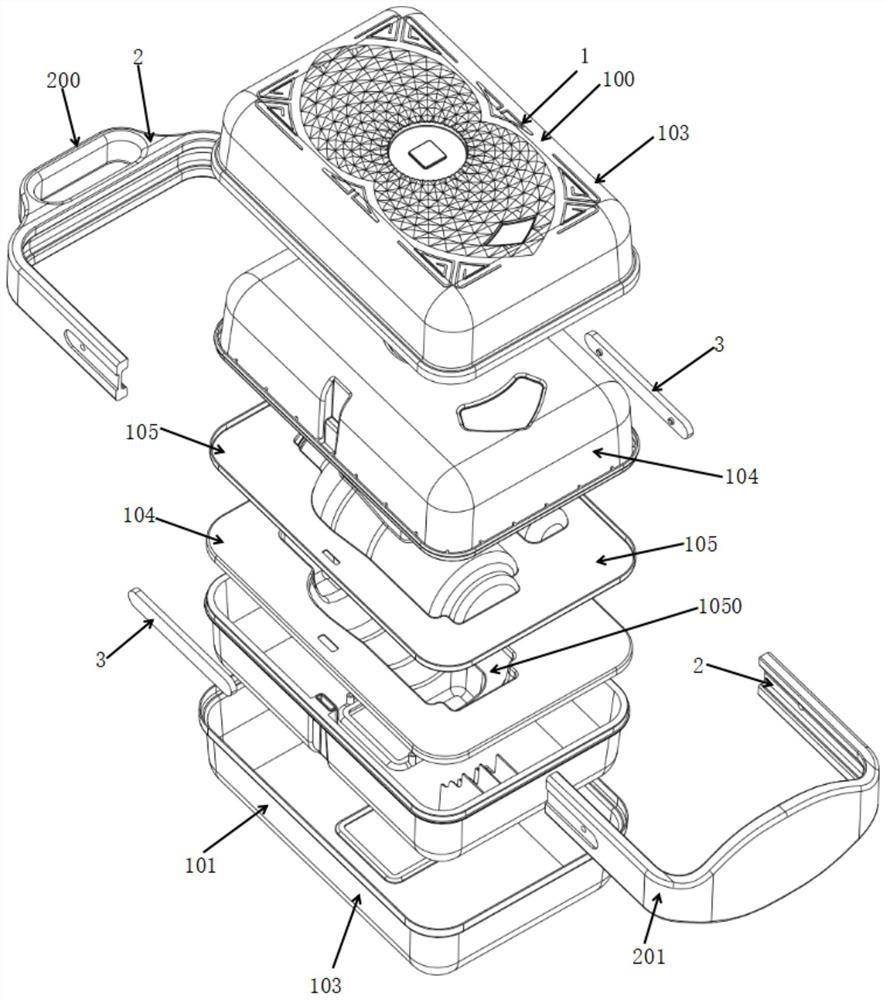

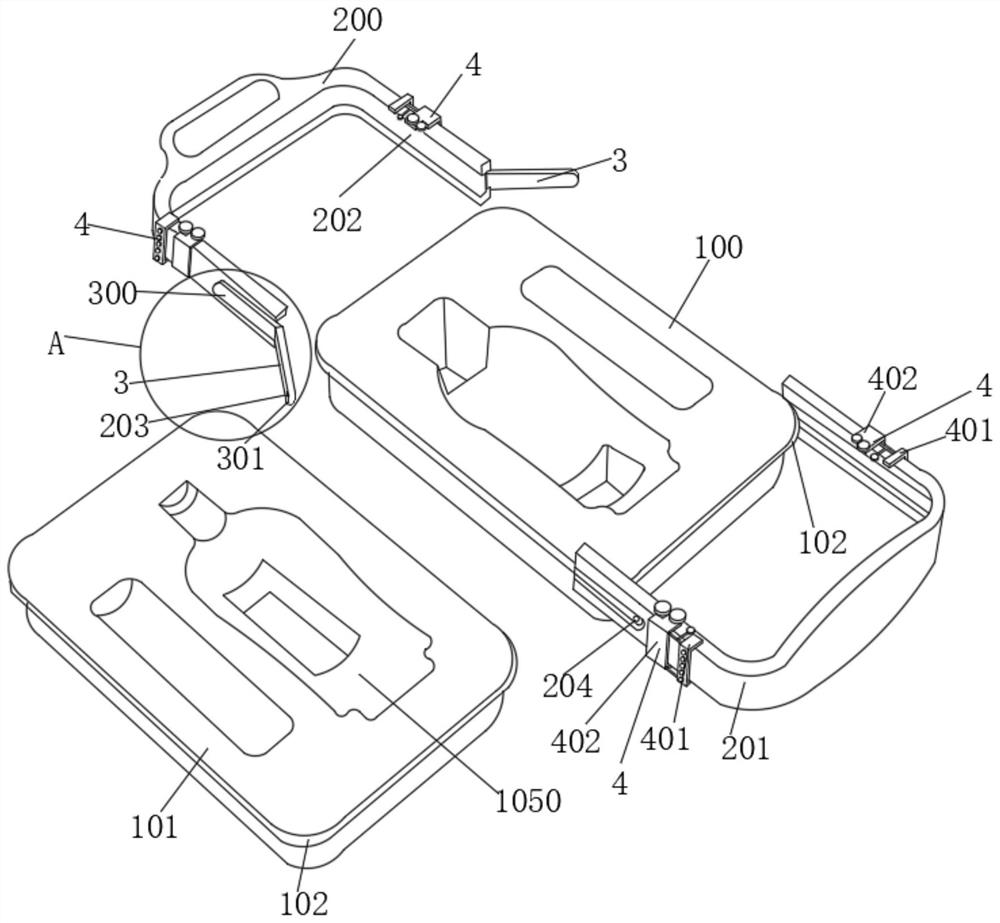

[0051] The embodiment of the present invention provides a lock box structure of a packaging box and a preparation process thereof, such as Figure 1-10 As shown, it includes a paper film box body 1, a handle 2 and a hardware lock 3. The paper film box body 1 includes an upper box body 100 and a lower box body 101, and the handle 2 includes an upper handle 200 and a lower handle. The hand 201, the outer sides of the openings of the upper box body 100 and the lower box body 101 are provided with stepped protruding annular edges, the edges are provided with slide rails 102, the upper handle 200 and the lower The inner side of the handle 201 is provided with a chute 202. After the upper case body 100 and the lower case body 101 are opened and fitted, the upper handle 200 and the lower handle 201 can both: pass through the chute 202 is slidably connected to the slide rail 102 of the upper box body 100 and the lower box body 101, the hardware lock 3 is used to lock the upper handle ...

Embodiment 2

[0058] On the basis of above-mentioned embodiment 1, described upper box body 100 and described lower box body 101 all comprise outer casing 103, middle casing 104 and placement cover 105;

[0059] The outer casing 103 and the intermediate casing 104 are both rectangular concave casing mechanisms, the intermediate casing 104 is sleeved in the outer casing 103, and the placing cover 105 is mounted on the intermediate casing On 104, the upper case body 100 and the lower case body 101 are assembled to form;

[0060] The placement cover 105 is provided with several placement slots 1050 with different shapes, and the placement slot 1050 of the box body 100 and the lower box body 101 can be mirrored to form a complete placement cavity. The storage cavity is used to store the objects;

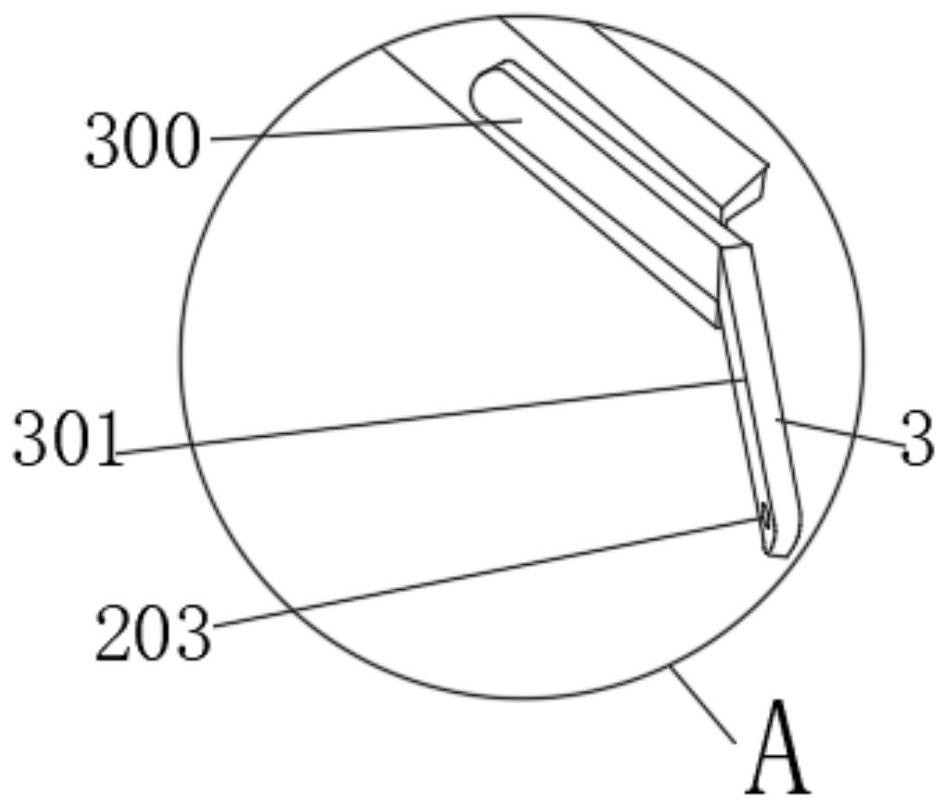

[0061] The hardware lock 3 includes a first lock body 300 and a second lock body 301, the first lock body 300 and the second lock body 301 are rotatably connected, and the first lock body 300 is conn...

Embodiment 3

[0064] On the basis of Embodiment 1 or 2, the upper handle 200 and the lower handle 201 are both provided with an auxiliary insertion mechanism 4;

[0065] The auxiliary insertion mechanism 4 includes a first connection table 401, a second connection table 402 and an adjustment structure 403, and the first connection table 401 and the second connection table 402 are connected by the adjustment structure 403;

[0066] The first connection platform 401 is provided with several bolt holes 400, the upper handle 200 and the lower handle 201 are bolted to the auxiliary insertion mechanism 4 through the bolt holes 400, and the second connection The table 402 is provided with two symmetrically arranged first auxiliary wheels 4020 and two symmetrically arranged second auxiliary wheels 4021. Both the first auxiliary wheels 4020 and the second auxiliary wheels 4021 are connected to the second auxiliary wheels The connection platform 402 is connected in rotation;

[0067] The adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com