Intelligent control method for balanced crushing of fine crushing workshop in machine-made gravel

An intelligent control, sand and gravel technology, applied in grain processing and other directions, can solve the problems of uneven operation of equipment, failure to detect in time, large fluctuations in particle size and size of medium and fine crushing, and ensure balanced operation and reduce labor costs. , to ensure the effect of product quality consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

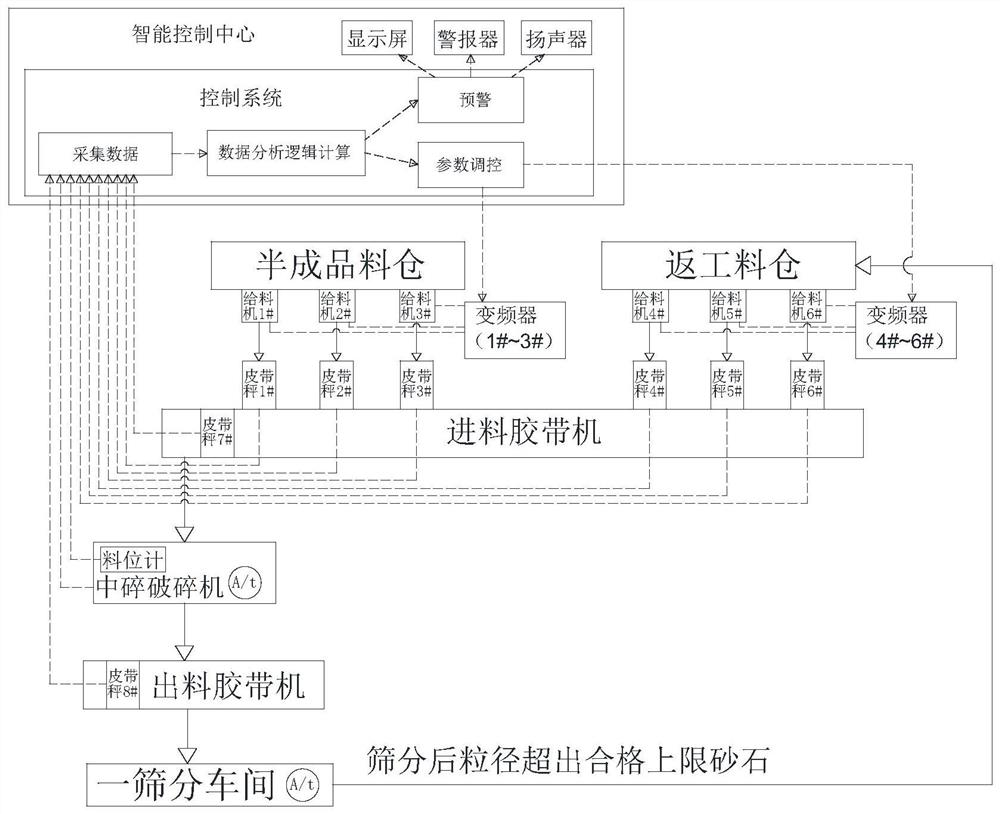

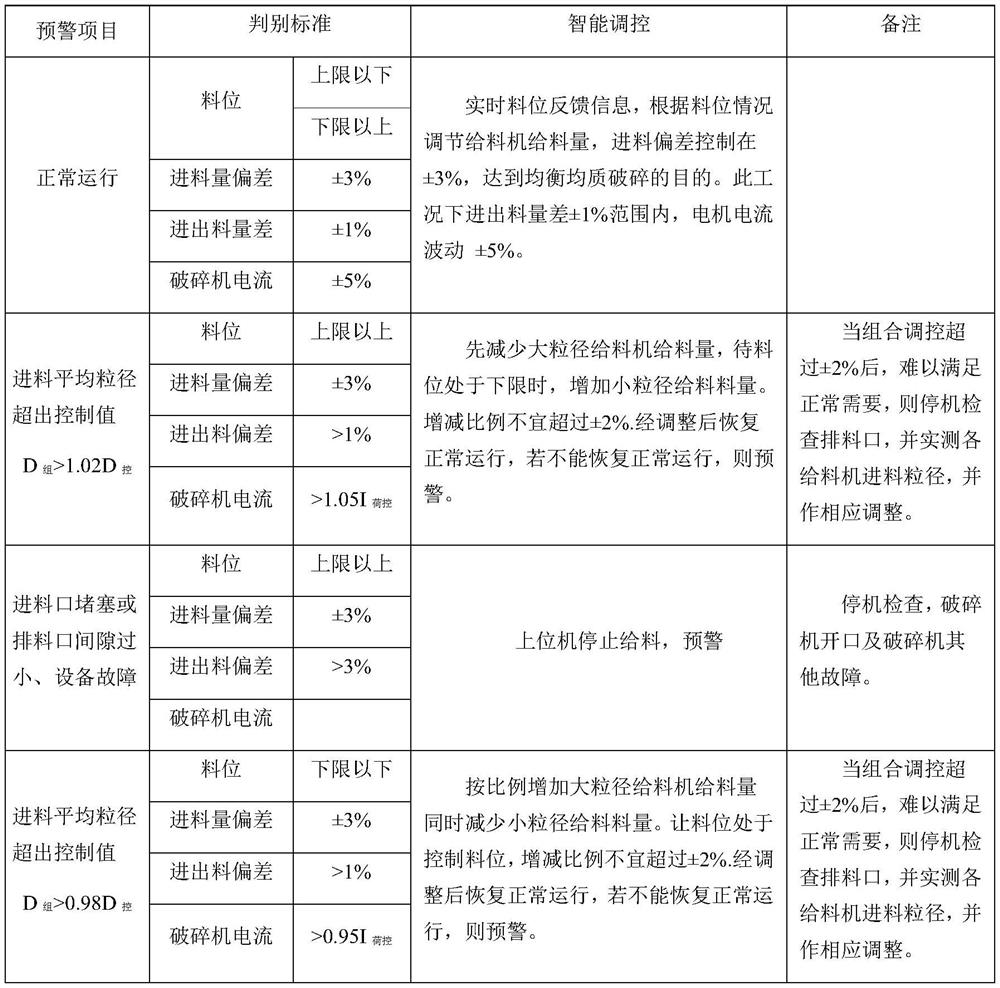

[0033] Such as figure 1 As shown, the adjustment silo includes the semi-finished product silo for coarse crushing output and warehousing and the rework silo for the medium and fine crushing that exceeds the upper limit of the qualified particle size. The two silos are respectively equipped with three reclaimers along the blanking center to the edge of the pile. point, take samples to calculate the average particle size of each feeding point, input the average particle size of each feeding point into the control system, calculate the weight ratio of each feeding point, and the intelligent control center controls the feeder of each feeding point to press The weight ratio is used to transport mineral materials to the feeding belt conveyor. The linear relationship between the motor frequency of the feeder and the conveying volume is obtained through productive experiments, and the control of the conveying volume is realized by controlling the motor frequency of the feeder through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com