Fuel cell comprising at least one traction member

A technology of fuel cells and traction parts, which is applied in the directions of fuel cells, circuits, electrical components, etc., can solve the problems of increasing the weight and overall size of the fuel cell 100, increasing the manufacturing cost, and being complicated in installation, and achieves weight reduction, quantity reduction, and compression. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

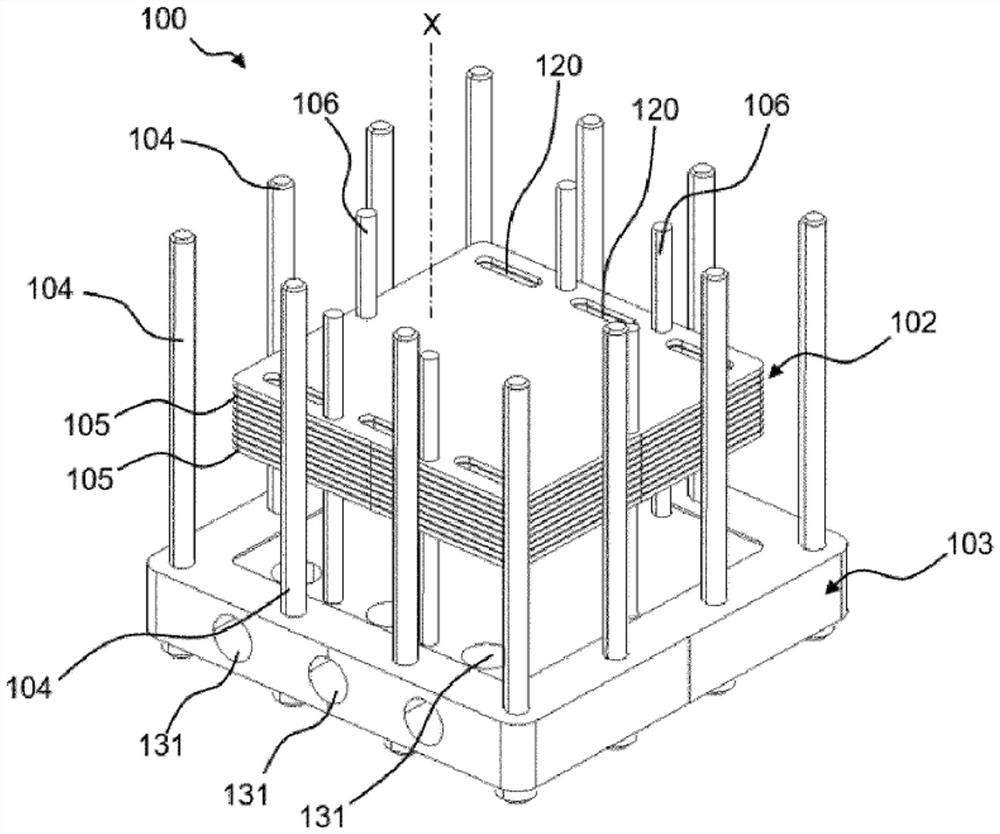

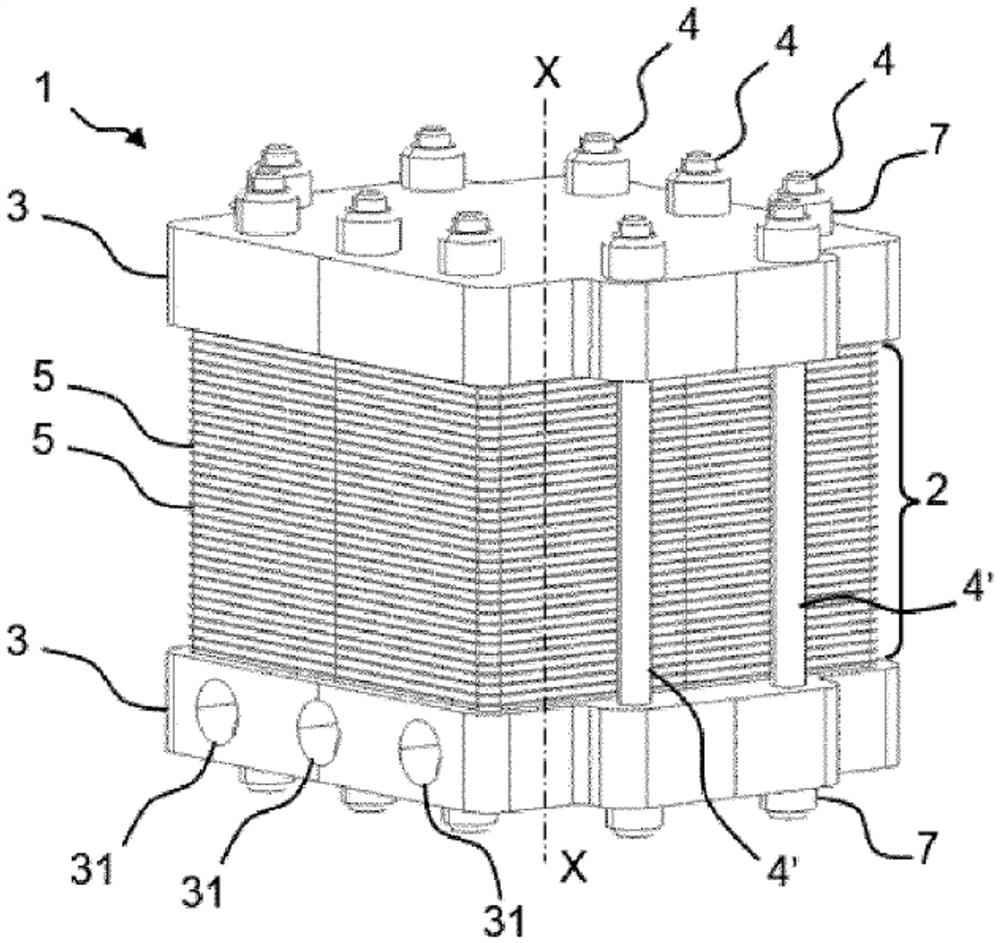

[0039] refer to image 3 , image 3 A fuel cell 1 generating electrical energy is generated by an electrochemical reaction in an embodiment of the present invention.

[0040]Traditionally, a different fluid is circulated in a fuel cell 1, thereby reacting electric energy. This reaction can be specifically a redox reaction between oxygen and hydrogen. Therefore, the fuel cell 1 is supplied with oxygen and hydrogen. The redox reaction also produces water, which is discharged from the fuel cell 1. In a preferred embodiment, the fuel cell 1 is a high temperature fuel cell, wherein the water produced by the reaction is a turbine. In fact, as will be described later, the vapor water is easy to discharge. The fuel cell 1 is also supplied with a coolant to release heat generated by the electrochemical reaction. The coolant is a heat transfer fluid, such as oil or water, which can be mixed with an additive.

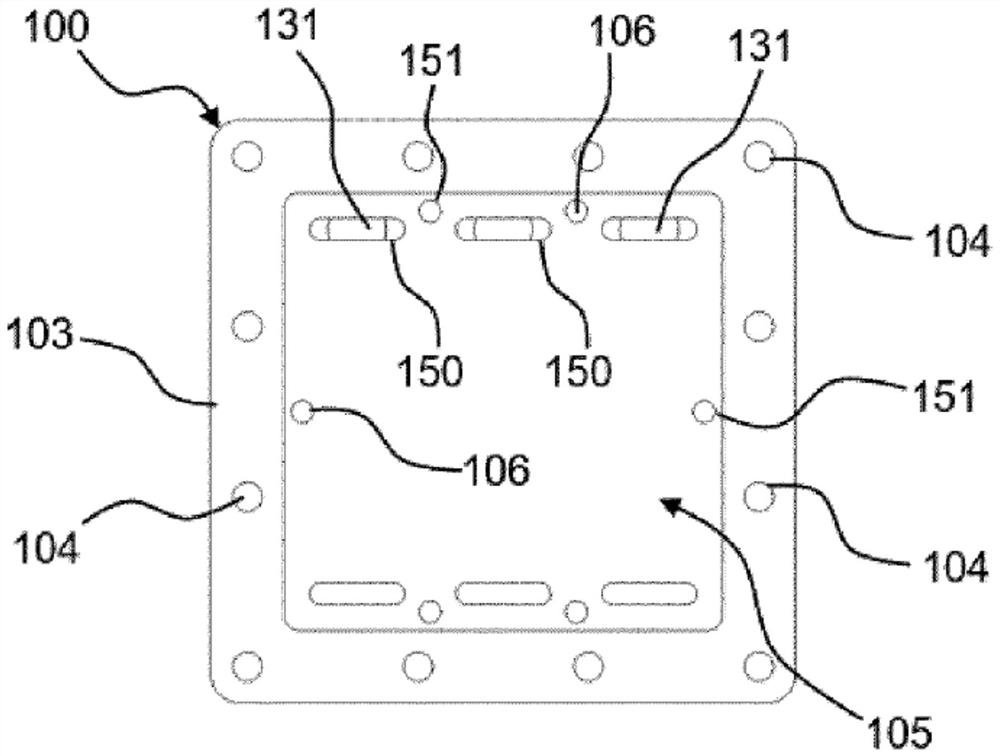

[0041] like image 3 and Figure 4 As shown, the fuel cell 1 includes a battery stack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com