A placement machine for the production of semiconductor electric components and its use method

A technology of electrical components and semiconductors, which is applied in the field of placement machines for the production of semiconductor electrical components. It can solve problems such as low yield rate, reduced quality of electrical components, and failure to use normally, so as to improve service life, prevent electrostatic damage, and improve heat dissipation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

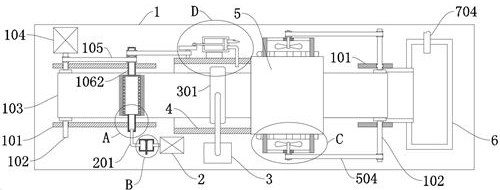

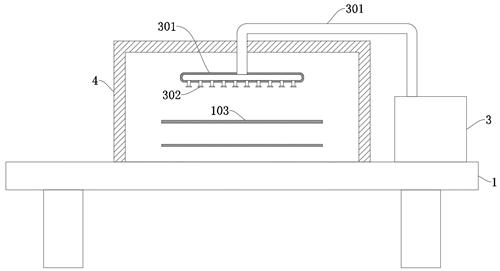

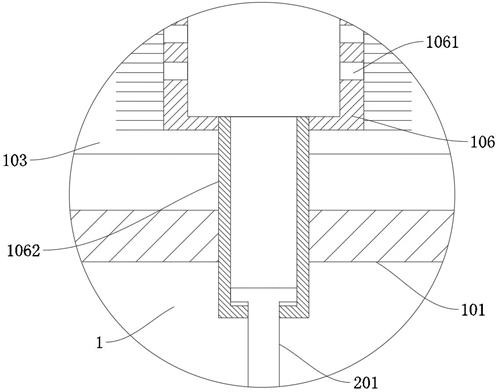

[0039] refer to Figure 1-8 , a placement machine for the production of semiconductor electrical components, comprising a mounting table 1, a mounting plate 101, a rotating roller 102, a conveyor belt 103, an air pump 2, a patch box 5, the mounting plate 101 is fixedly connected to the mounting table 1, and rotates The rollers 102 are rotatably connected on the mounting plate 101, the conveyor belt 103 is connected between the rotating rollers 102, and also include: a brush roller 106, which is rotatably connected between the mounting plates 101 through a hollow tube 1062, and the hollow tubes 1062 are fixedly connected respectively At the two ends of the brush roller 106, and one group communicates with the brush roller 106, wherein, the hollow tube 1062 at one end is connected with the rotating roller 102 through the first belt 105; air holes 1061 are provided in multiple groups on the brush roller 106; Air pipe 201, one end is fixedly connected to the suction end of air pum...

Embodiment 2

[0046] refer to figure 1 and 4 , which is basically the same as in Embodiment 1, furthermore: the installation platform 1 is fixedly connected with a filter box 202, the filter box 202 is located between the hollow pipe 1062 and the air pump 2, the air suction pipe 201 leads to the filter box 202, and the filter box 202 is filtered A filter screen 203 is connected in the box 202;

[0047] By setting the filter box 202 in the middle of the suction pipe 201, the dust sucked by the suction pipe 201 can be blocked on the filter screen 203, preventing the dust from entering the suction pump 2 and causing damage to the suction pump 2 after a long time.

Embodiment 3

[0049] refer to figure 1 and 4 , is basically the same as Embodiment 1, further is: the filter screen 203 is slidingly connected in the filter box 202;

[0050] Periodically by pulling out the filter screen 203 from the filter box 202, the dust on the filter screen 203 is cleaned to prevent the dust from clogging the filter screen 203, causing inability to suck air from the air hole 1061 and improving the air suction effect of the air hole 1061.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com