Printed circuit board with embedded array micro-channels and preparation method of printed circuit board

A technology of printed circuit boards and micro-channels, which is applied in the directions of printed circuit manufacturing, printed circuits, printed circuit components, etc., to achieve the effect of increasing integration density and realizing arrayed high-density transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

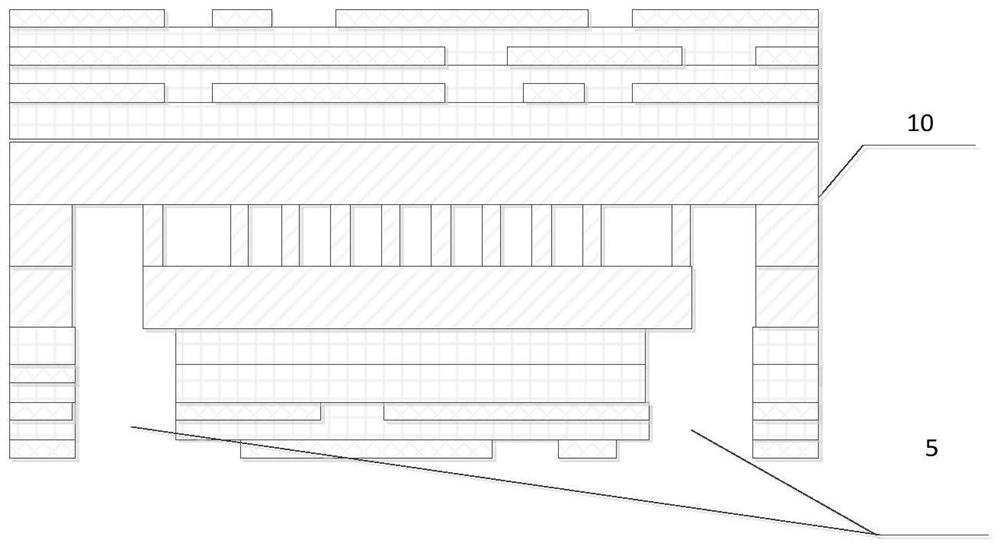

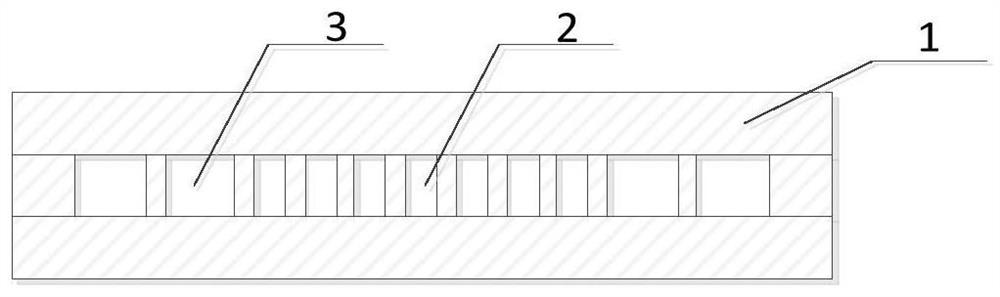

[0042] as attached figure 1 As shown, it is a schematic cross-sectional view of a printed circuit board embedded with array micro-channels provided in this embodiment. The printed circuit board embedded with micro-channels specifically includes a metal core board 1, and the upper surface of the metal core board 1 is The top multi-layer wiring layer 6 is provided, and the bottom multi-layer wiring layer 9 is provided on the lower surface. The metal core board 1 is embedded with an array of heat-dissipating micro-channels 2 connected to the liquid inlet and outlet 5 .

[0043] as attached Figure 4 , 5 Shown is the top multilayer wiring layer 6 and the bottom multilayer wiring layer 9 of the metal core board 1 provided in this embodiment, and the top multilayer wiring layer 6 and the bottom multilayer wiring layer 9 are respectively provided with organic wiring layers distributed at intervals 7 and copper wiring layer 8 to realize a multilayer circuit.

[0044] Wherein, the a...

Embodiment 2

[0052] as attached Figure 7 Shown is a method for preparing a printed circuit board with an embedded array of microfluidic channels provided in this embodiment. The method specifically includes the following steps:

[0053] Step 1: Provide a flat and smooth copper core board.

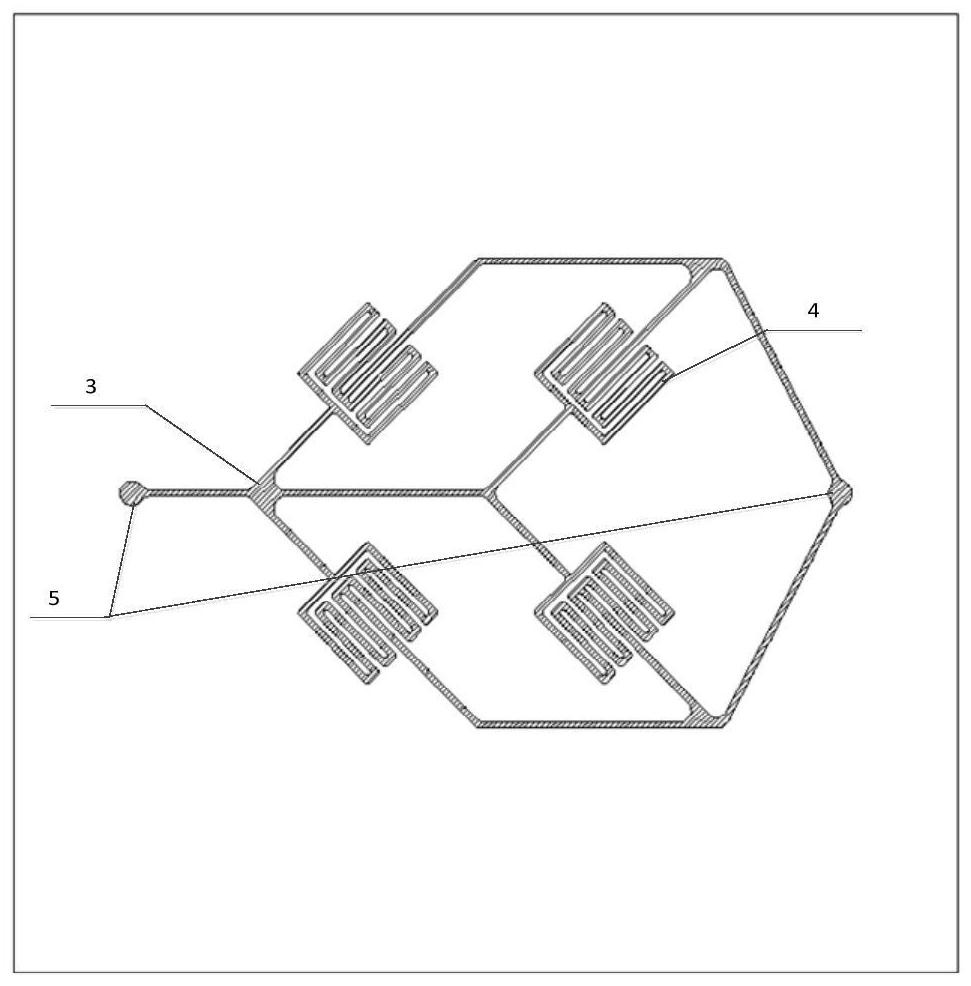

[0054] Step 2: Preparing an arrayed high-efficiency array heat-dissipating microfluidic channel unit and a shunt network on the copper core board by precision machining.

[0055] Step 3: Weld the copper core board prepared with the arrayed high-efficiency array heat dissipation microchannel unit and the shunt network with another copper core board by vacuum diffusion welding to obtain a copper core board with embedded array microchannels.

[0056] Step 4: Provide the multi-layer wiring layer on top of the metal core board prepared by the printed circuit board lamination process.

[0057] Step five: providing a multilayer wiring layer at the bottom of the metal core board prepared by a printed circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com