Pulse fiber laser seed source and pulse adjusting method

A fiber laser and fiber combiner technology, applied in the laser field, can solve the problems of repetition frequency adjustment limitation, etc., and achieve the effect of flexible design, industrialization, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

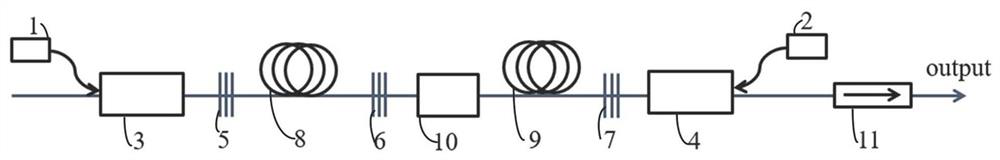

[0072] This embodiment provides a kind of pulsed fiber laser seed source, its structure is as follows figure 1 As shown, it includes: a first grating 5, a second grating 6, a third grating 7, a first pumping source 1, a second pumping source 2, a first fiber combiner 3, a second fiber combiner 4, A first gain fiber 8 , a second gain fiber 9 , a modulator 10 and an output device 11 .

[0073] Among them, the first pump source 1 and the second pump source 2 use semiconductor laser diodes with a center wavelength of 915nm or 976nm; the first fiber combiner 3 and the second fiber combiner 4 use (2+1) 1 Fiber beam combiner, such as 10 / 125 type, 20 / 125 type; the first grating 5, the second grating 6 and the third grating 7 are reflective fiber Bragg gratings, the first grating 5 is a high-reflection grating, and the second grating The grating 6 and the third grating 7 are partially reflective gratings, and the reflectivity is greater than 0 and less than 1; the first gain fiber 8 a...

Embodiment 2

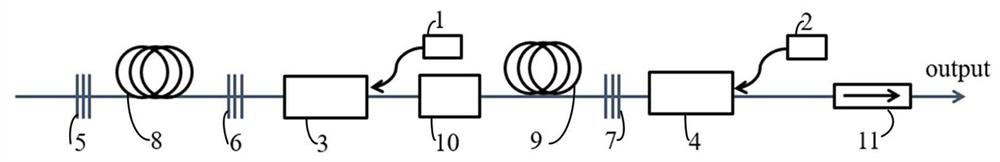

[0080] The present embodiment provides the second kind of pulsed fiber laser seed source, its structure is as follows figure 2 As shown, the basic structure is the same as figure 1 Similar, the difference is that the positions of the second pump source 2 and the second fiber combiner 4 are different. In this embodiment, the second pump source 2 and the second fiber combiner 4 are placed in the third grating 7 and the second gain Between the optical fibers 9.

Embodiment 3

[0082] The present embodiment provides the third kind of pulsed fiber laser seed source, its structure is as follows image 3 As shown, the basic structure follows figure 1 Similar, the difference is that the positions of the first pump source 1 and the first fiber combiner 3 are different. In this embodiment, the first pump source 1 and the first fiber combiner 3 are placed in the second grating 6 and the modulator 10 between.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com