Method, system and device for online classification and evaluation of slurry quality in desulfurization system

A desulfurization system and slurry technology, applied in chemical process analysis/design, data processing applications, instruments, etc., can solve the problems of delay, complex chemical composition, difficult to control the pH value of slurry, etc., and achieve the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

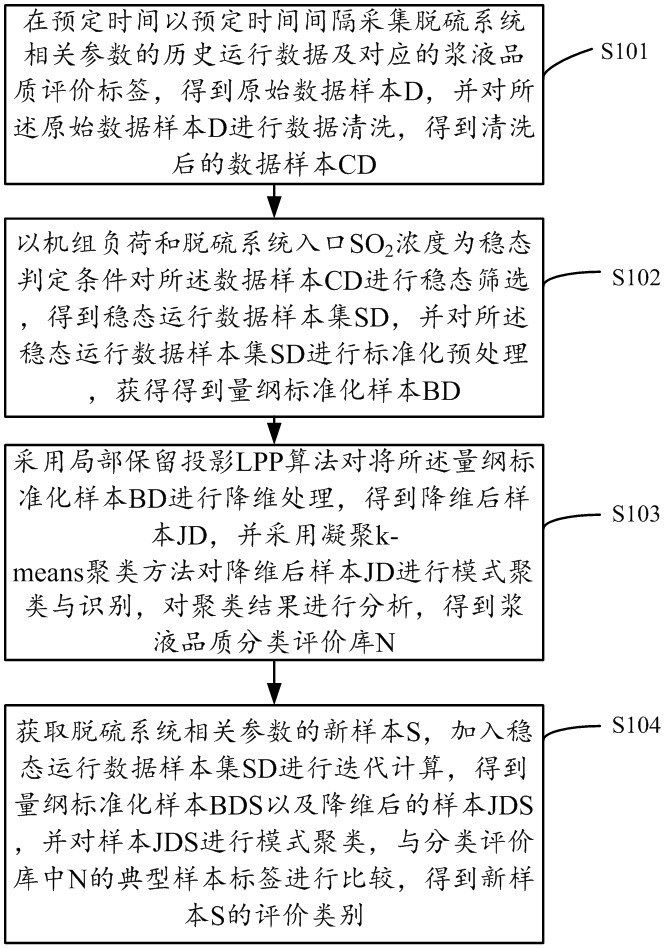

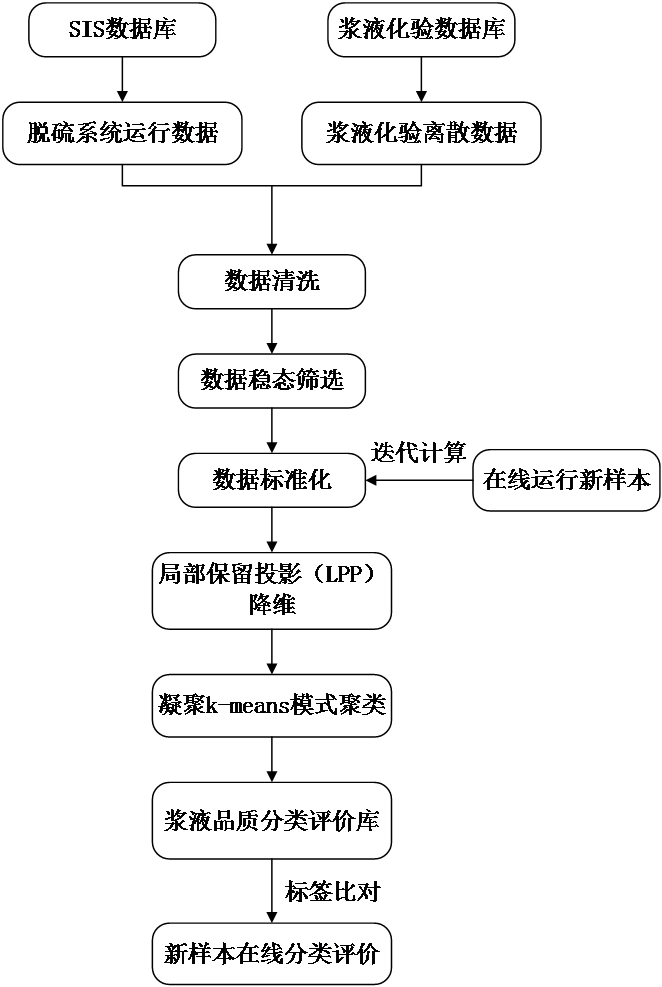

Method used

Image

Examples

Embodiment 1

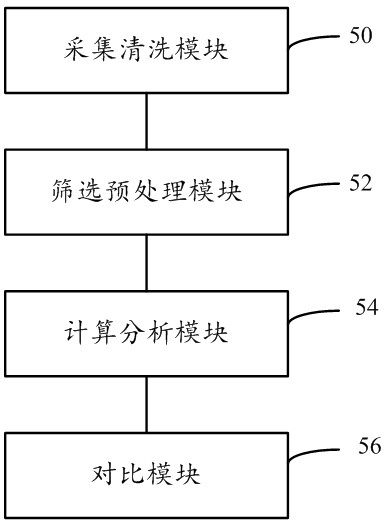

[0063] An embodiment of the present invention provides an online classification and evaluation device for slurry quality in a desulfurization system, such as Figure 4 As shown, it includes: a memory 60, a processor 62, and a computer program stored on the memory 60 and operable on the processing 62. When the computer program is executed by the processor 62, it is implemented as in the method embodiment. steps described.

Embodiment 2

[0065] An embodiment of the present invention provides a computer-readable storage medium, where a program for realizing information transmission is stored on the computer-readable storage medium, and when the program is executed by the processor 62, the steps described in the method embodiments are implemented.

[0066] The computer-readable storage medium described in this embodiment includes but is not limited to: ROM, RAM, magnetic disk or optical disk, and the like.

[0067] It should be noted that the embodiment of the storage medium in this specification and the embodiment of the blockchain-based service provision method in this specification are based on the same inventive concept, so the specific implementation of this embodiment can refer to the aforementioned corresponding desulfurization system slurry The implementation of the quality online classification and evaluation method will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com