Welding spot quality detection method and device based on multi-model fusion and storage medium

A technology of solder joint quality and detection method, which is applied in measurement devices, character and pattern recognition, instruments, etc., can solve problems such as outflow of unqualified solder joints, low sampling frequency, hidden safety hazards, etc., and achieves improved robustness and simple implementation. , the effect of good anti-noise ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

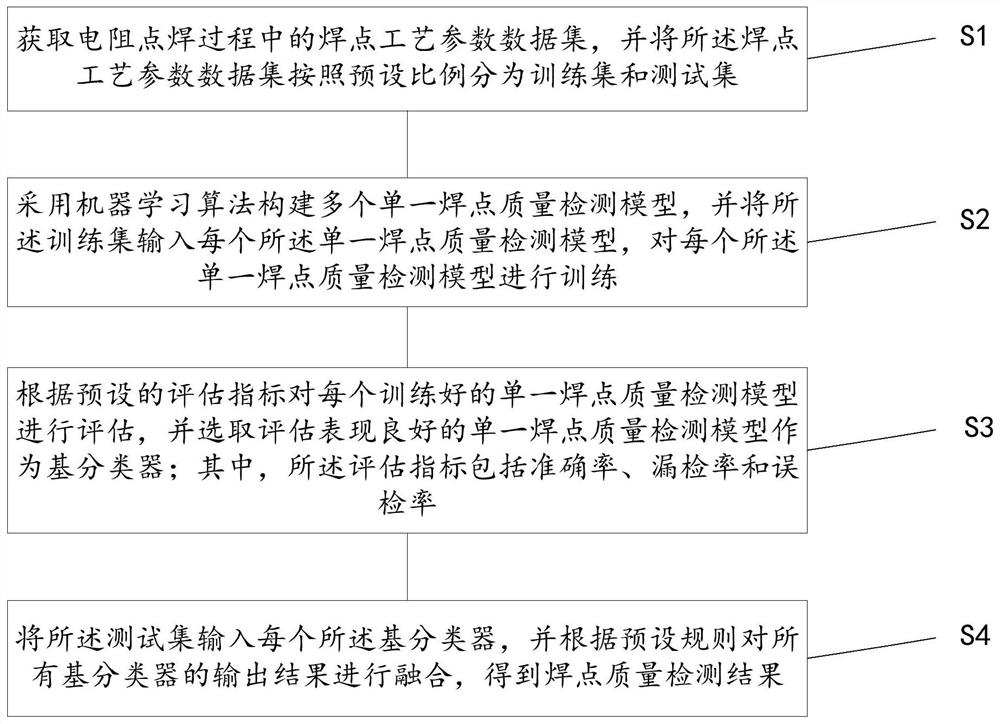

[0044] see figure 1 , figure 1 It is a schematic flowchart of a preferred embodiment of a method for detecting the quality of solder joints based on multi-model fusion provided by the present invention. The method for detecting the quality of solder joints based on multi-model fusion includes:

[0045]S1. Obtain a data set of solder joint process parameters in the process of resistance spot welding, and divide the data set of solder joint process parameters into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com