Riser design method of automobile motor end cover and its casting mold

A technology of motor end cover and design method, which is applied in computer-aided design, manufacturing tools, casting and molding equipment, etc., can solve the problems of shrinkage porosity, inconvenient operation of riser parts, low processing efficiency, etc., and achieves simple and clear design ideas. The process is simple and efficient, and the effect of mold preparation is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

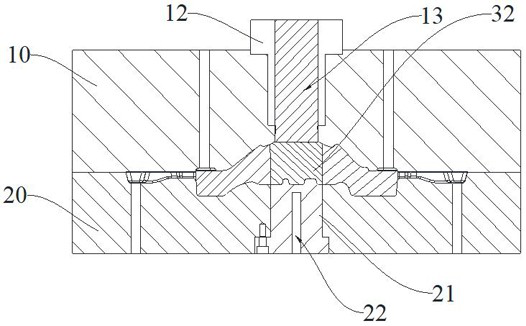

[0060]A riser design method for an automobile motor end cover, comprising the following steps:

[0061] (1) Apply UG-3D software section analysis to find out the heat joint, which is located in the middle of the casting;

[0062] (2) The thermal junction is equivalent to a cylindrical structure, and the size of the thermal junction is determined: radius R 1 30mm, height H 1 50mm;

[0063] (3) Calculate the volume V of the thermal junction 1 =π×R 1 2 ×H 1 =3.14×30 2 ×50=141300mm 2 , to calculate the mass M of the thermal junction 1 =ρ 1 ×V 1 , where ρ 1 is the density of thermal nodes, V 1 is the volume of thermal junction, where ρ 1 =2700kg / m 3 , namely M 1 =ρ 1 ×π×R 1 2 ×H 1 , Substitute the above data into the formula to get M 1 =0.382kg.

[0064] (4) Introducing M 2 =2M 1 Calculation formula to calculate the mass M of the riser 2 =a×ρ 1 ×π×R 1 2 ×H 1 , that is, M 2 =0.764kg.

[0065] (5) Calculate the volume V of the riser 2 = M 2 / ρ 2 , whe...

Embodiment 2

[0068] A riser design method for the end cover of an automobile motor is the same as that in Embodiment 1, except that the mass of the thermal joint in step (4) is M 1 , the mass of the riser is M 2 , and M 2 =0.5M 1 .

Embodiment 3

[0070] A riser design method for the end cover of an automobile motor is the same as that in Embodiment 1, except that the mass of the thermal joint in step (4) is M 1 , the mass of the riser is M 2 , and M 2 = M 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com