Method for testing initial stripping time of adhesiveness of coarse aggregate and asphalt

A test method and coarse aggregate technology, applied in the direction of measuring devices, analysis materials, instruments, etc., can solve the problems of long test results, large deviations of test results, water temperature fluctuations, etc., to reduce the influence of human factors and avoid water overheating Phenomenon, the effect of avoiding judgment bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

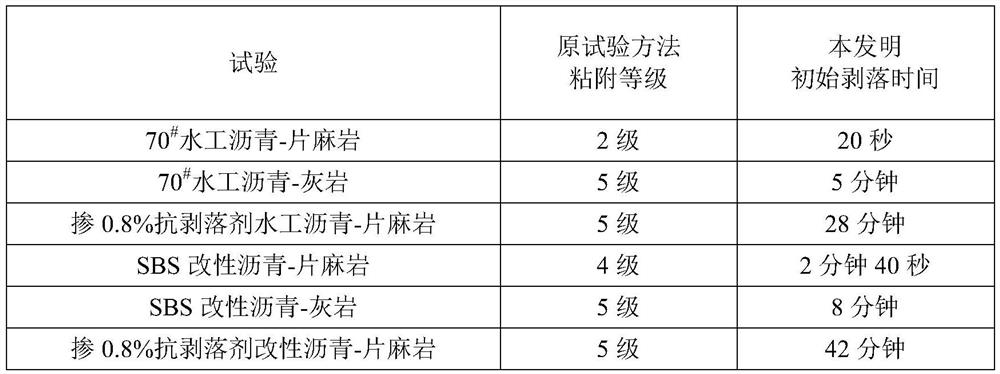

[0040] Carry out the adhesion test according to the test method in the adhesion test of 6.11 coarse aggregate and asphalt in "Hydraulic Asphalt Concrete Test Regulations" (DL / T5362-2018) and the test method of the present invention respectively, and test the acidic gneiss coarse aggregate In the two test methods, the adhesion effect classification or initial peeling time difference between alkaline limestone coarse aggregate and hydraulic asphalt, modified asphalt, and anti-stripping agent was added, and 5 coarse aggregates were taken for each group.

[0041] The present invention adopts concrete steps as follows:

[0042] 1) Take 5 coarse aggregates with a particle size of 13mm-19mm, put them in an enamel plate, wash them, dry them in an oven with a set temperature of 105°C for 2 hours, take them out and cool them to room temperature for later use;

[0043] 2) Lay a single layer of gravel covering about 1 / 8 of the bottom area of the beakers at the bottom of five 1000mL beak...

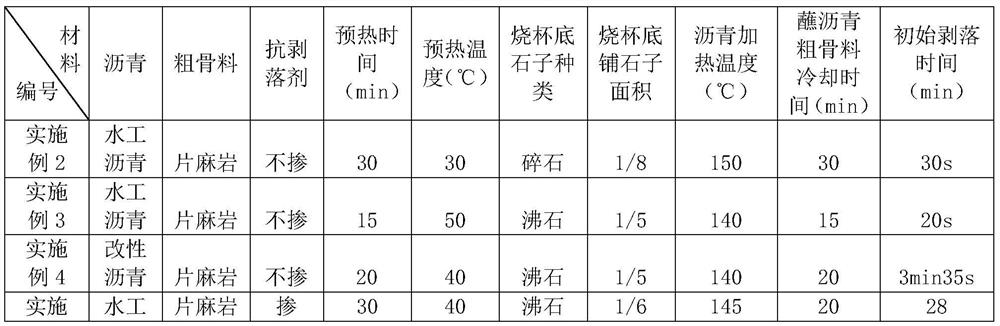

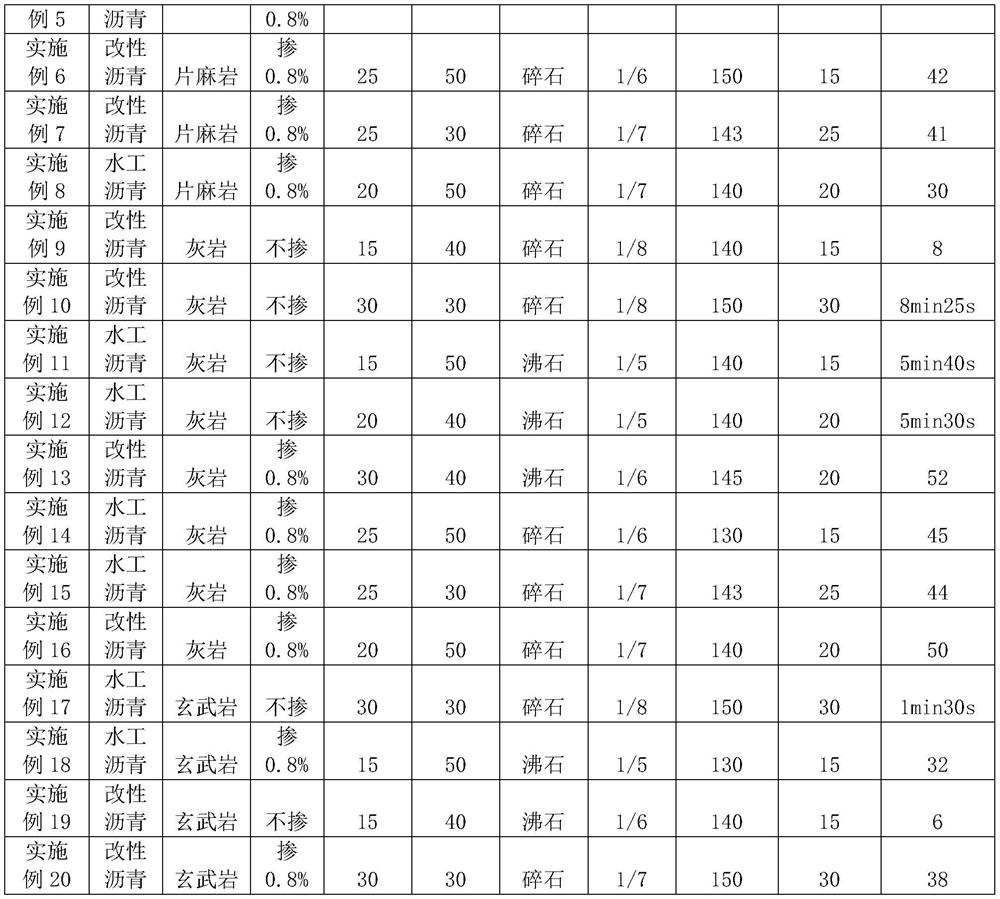

Embodiment 2

[0053] 1) Take acidic coarse aggregate gneiss particles with a particle size of 13mm-19mm, put them in an enamel plate, wash them, dry them in an oven with a set temperature of 105°C for 2 hours, take them out and cool them to room temperature for later use;

[0054] 2) Lay a single layer of gravel covering about 1 / 8 of the bottom area of the beakers at the bottom of five 1000mL beakers, then fill the beakers with water and put them on a heating furnace with an asbestos net, and boil the water to a slight boil;

[0055] 3) Fasten the coarse aggregates one by one with thin iron wires, and place them in an oven with a set temperature of 30°C for 30 minutes to preheat;

[0056] 4) Preheated to 150 ℃ 70 # Take the hydraulic asphalt out of the oven, take 5 preheated coarse aggregates, and immerse them in the asphalt for 45 seconds, so that the surface of the coarse aggregates is completely covered by the asphalt;

[0057] 5) Hang the asphalt-coated coarse aggregate on the test f...

Embodiment 3

[0061] 1) Take acidic coarse aggregate gneiss particles with a particle size of 13mm-19mm, put them in an enamel plate, wash them, dry them in an oven with a set temperature of 105°C for 2 hours, take them out and cool them to room temperature for later use;

[0062] 2) Lay a single layer of zeolite at the bottom of three 1000mL beakers, accounting for about 1 / 5 of the bottom area of the beakers, then fill the beakers with water and put them on a heating furnace with an asbestos net, and boil the water to a slight boil;

[0063] 3) Fasten the coarse aggregates one by one with thin iron wires, and place them in an oven with a set temperature of 50°C for 15 minutes to preheat;

[0064] 4) Preheated to 140 ℃ 70 # Take the hydraulic asphalt out of the oven, take 3 preheated coarse aggregates, and immerse them in the asphalt for 45 seconds, so that the surface of the coarse aggregates is completely covered by the asphalt;

[0065] 5) Hang the asphalt-coated coarse aggregate on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com