Multifunctional composite scaffold system

A kind of scaffolding and composite technology, which is applied to the accessories of scaffolding, scaffolding supported by house structures, buildings, etc., can solve the problems of increasing the construction time of exterior wall decoration, poor stability of cantilevered scaffolding, and scaffolding stuck, etc., to reduce Probability of accidents, reduced construction costs, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

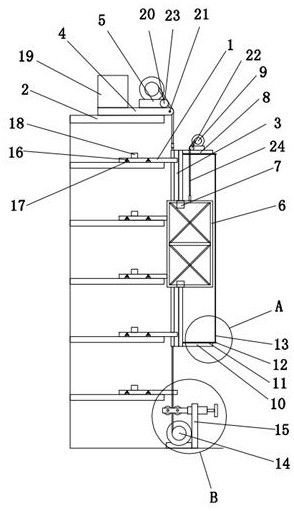

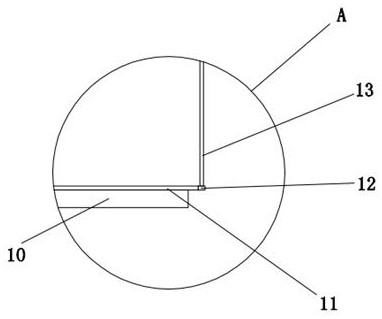

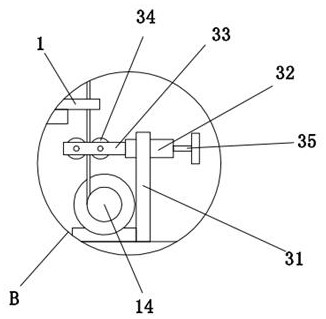

[0033] see Figure 1-6 , a multifunctional composite scaffolding system, including a cantilever frame 1 and a climbing frame 4 fixed on multiple floors 2, the climbing frame 4 is fixedly installed on the uppermost floor 2, and the cantilever frame 1 is provided with multiple, And a plurality of cantilever frames 1 are installed on other floor slabs 2 correspondingly one by one, and the outer end of the cantilever frame 1 is provided with two guide rail chute 25 symmetrically, and the guide rail chute 25 on the plurality of cantilever frames 1 vertically Alignment setting, sliding connection with climbing guide rail 3 in the guide rail chute 25 of alignment, the upper end of climbing frame 4 is fixedly connected with climbing hoist 5, and the winch of climbing hoist 5 is fixedly connected with climbing guide rail 3 upper end by climbing traction rope 23, and climbing guide rail 3 The lower end of the lower end is fixedly connected with the traction machine 14 through the climbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com