Production process of high-breathability fabric for western-style clothes

A production process and highly breathable technology, applied in the field of fabrics, can solve problems such as easy to wrinkle and affect the appearance of suits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The present embodiment is anti-wrinkle agent, and the preparation process of described anti-wrinkle agent is as follows:

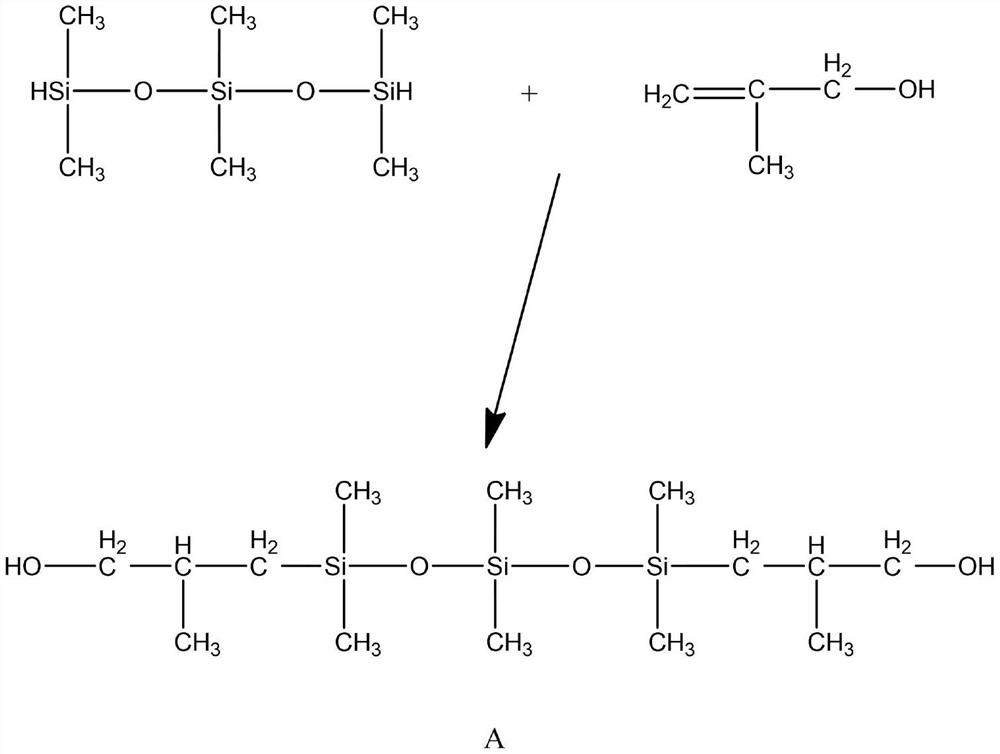

[0031] S1: Add hydrogen-terminated dimethyl (siloxane and polysiloxane) and methallyl alcohol into a four-necked flask equipped with a thermometer, condenser, and stirrer, and stir at a speed of 100r / The temperature was raised to 50°C while stirring under the condition of min, and the temperature rise rate was controlled to be 2°C / min. After that, the catalyst chloroplatinic acid was added, and the temperature was continued to rise to 85°C, and the reaction was stirred at a constant temperature for 4 hours. After that, the reaction solution was suction filtered, and the filtrate was rotary evaporated. Collect the rotary steamed product to obtain intermediate A; control the molar ratio of the hydrogen-terminated dimethyl (siloxane and polysiloxane) to methallyl alcohol to be 1:1.2, and the chloroplatinic acid The addition amount is 60ppm;

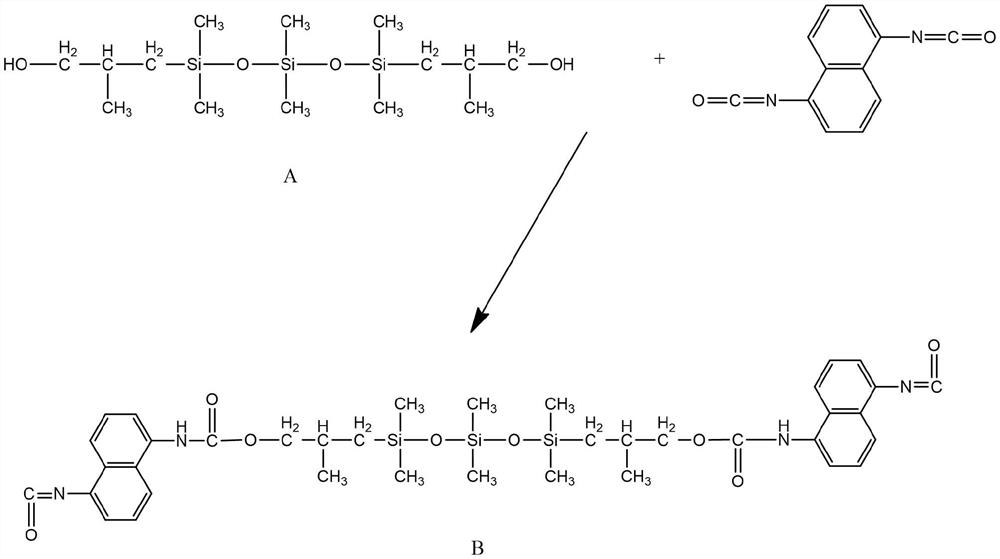

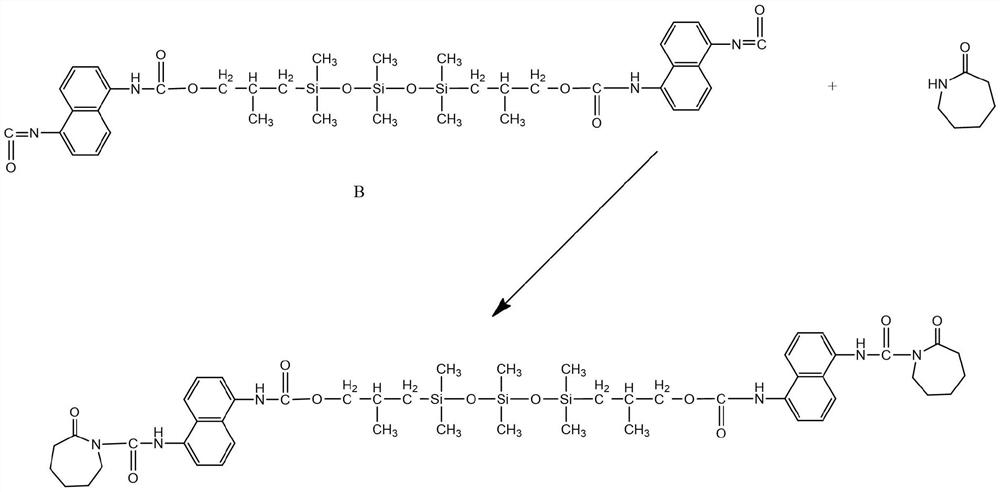

[0032] ...

Embodiment 2

[0035] The present embodiment is anti-wrinkle agent, and the preparation process of described anti-wrinkle agent is as follows:

[0036] S1: Add hydrogen-terminated dimethyl (siloxane and polysiloxane) and methallyl alcohol into a four-necked flask equipped with a thermometer, condenser, and stirrer, and stir at a speed of 300r / The temperature was raised to 50°C while stirring under the condition of min, and the temperature rise rate was controlled to be 2°C / min. After that, the catalyst chloroplatinic acid was added, and the temperature was continued to rise to 85°C. The reaction was stirred at a constant temperature for 5 hours, and then the reaction solution was filtered with suction, and the filtrate was rotary evaporated. Collect the rotary steamed product to obtain intermediate A; control the molar ratio of the hydrogen-terminated dimethyl (siloxane and polysiloxane) to methallyl alcohol to be 1:1.5, and the chloroplatinic acid The addition amount is 100ppm;

[0037]S2...

Embodiment 3

[0040] This embodiment is a production process for a highly breathable fabric for suits, comprising the following steps:

[0041] Step 1: Weaving and molding silk fibers to make outer fabric, and placing the outer fabric in the anti-wrinkle finishing solution with a bath ratio of 1:20, and using two dipping and two rolling methods for treatment. First, in an environment with a temperature of 80°C Pre-baked for 2 minutes in the middle, and then baked for 3 minutes in an environment with a temperature of 140° C. to obtain an anti-wrinkle outer fabric; wherein, the anti-wrinkle finishing solution is a mixed solution of an anti-wrinkle agent and fatty alcohol polyoxyethylene ether, and the anti-wrinkle agent The mass concentration is 60g / L;

[0042] Step 2: Weaving and forming polyester fiber to make middle layer fabric;

[0043] Step 3: Weaving and forming the cotton fiber to make the inner layer fabric;

[0044] Step 4: bonding and pressing the anti-wrinkle outer layer fabric,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com