A kind of environmental protection and energy-saving material for the surface layer of sports venues, its preparation method and application

An environmental protection, energy saving, venue technology, applied in the direction of sustainable manufacturing/processing, climate sustainability, chemical industry, etc., can solve the problem of poor sound-absorbing and noise-reducing performance of surface materials, limited applications, and inability to apply to indoor sports venues, etc. problems, to achieve the effect of good elasticity, less interference of climatic conditions, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

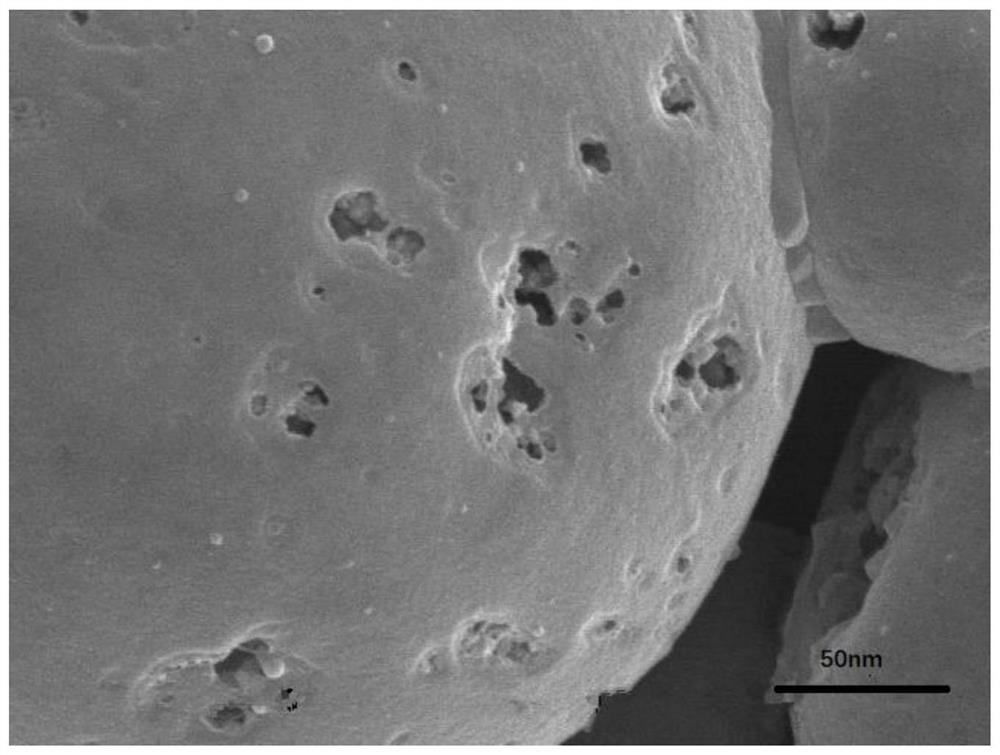

Image

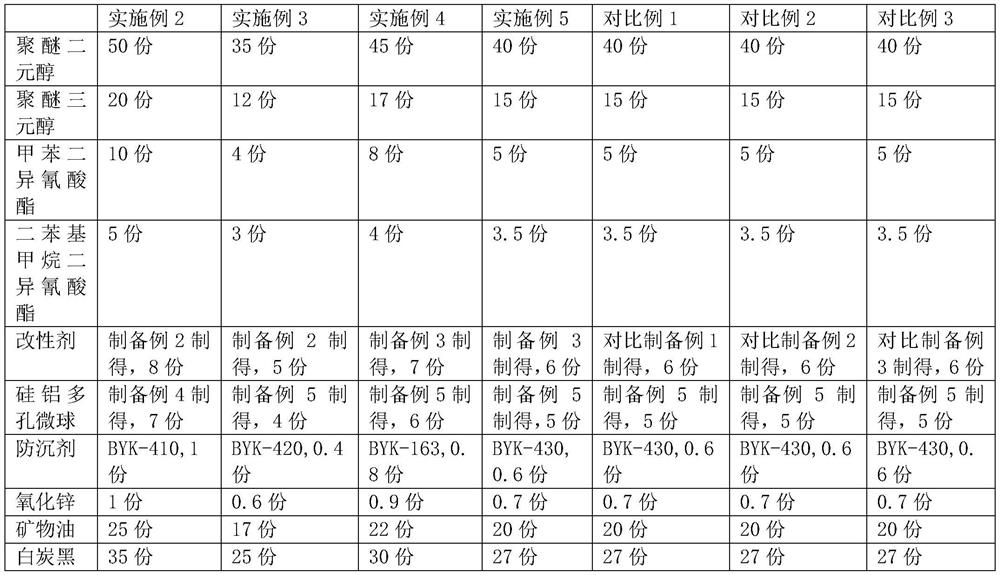

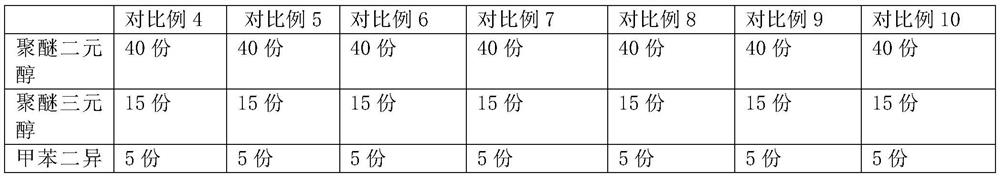

Examples

Embodiment 8

[0040] The polystyrene microspheres in Example 8 were purchased from Thermo Fisher Scientific Co., Ltd., and the particle size was between 200-400 nm. Potassium hexatitanate whisker (length 2mm, L / D=5) Tangshan Whisker Composite Material Co., Ltd.; potassium carbonate whisker, length 20 μm, L / D=20, Shanghai Quanxin Import and Export Trade Co., Ltd.; titanium Ester coupling agent TMC-201, titanate coupling agent TMC-27, ester coupling agent TMC-401, industrial grade, Nanjing Shuguang Chemical Co., Ltd.; silane coupling agent KH550, silane coupling agent KH570, silane Coupling agent KH580, silane coupling agent KH602, industrial grade, Nanjing Shuguang Chemical Co., Ltd.; aluminate coupling agent DL-411D, aluminate coupling agent DL-411, industrial grade, Guangzhou Yuantai Synthetic Materials Co., Ltd. ; Ethylene oxide-oxypropylene triblock copolymer PEO20-PPO70-PEO20 (P123); anti-settling agent BYK-163, anti-settling agent BYK-410, anti-settling agent BYK-420, anti-settling age...

preparation example 1

[0041] Preparation Example 1 Modifier preparation

[0042] S1. Dissolve 1g of titanate coupling agent TMC-201 in 100g of ethanol, add 20g of potassium hexatitanate whiskers, ultrasonically disperse for 1.5h, separate at 2500r / min for 12min, remove the supernatant, and use anhydrous Washing with ethanol, repeating the operation 3 times, and drying to obtain the modified potassium hexatitanate whiskers;

[0043] S2. Dissolve 2g of silane coupling agent KH550 in 100g of ethanol, add 25g of calcium carbonate whiskers, ultrasonically disperse for 1.5h, separate at 2500r / min for 12min, remove the supernatant, wash with absolute ethanol, repeat operation 3 Second, dry to obtain modified calcium carbonate whiskers;

[0044] S3. After uniformly mixing the modified potassium hexatitanate whiskers in step S1 and the modified calcium carbonate whiskers in step S2, place them in an oven and dry at 90° C. for 3 hours to obtain a modifier.

preparation example 2

[0045] Preparation example 2 Modifier preparation

[0046] S1. Dissolve 3g of titanate coupling agent TMC-27 in 100g of ethanol, add 30g of potassium hexatitanate whiskers, ultrasonically disperse for 1.5h, separate at 2500r / min for 12min, remove the supernatant, and use anhydrous Washing with ethanol, repeating the operation 3 times, and drying to obtain the modified potassium hexatitanate whiskers;

[0047] S2. Dissolve 4g of silane coupling agent KH580 in 100g of ethanol, add 35g of calcium carbonate whiskers, ultrasonically disperse for 1.5h, separate at a speed of 2500r / min for 12min, remove the supernatant, wash with absolute ethanol, repeat operation 3 Second, dry to obtain modified calcium carbonate whiskers;

[0048] S3. After uniformly mixing the modified potassium hexatitanate whiskers in step S1 and the modified calcium carbonate whiskers in step S2, place them in an oven and dry at 90° C. for 3 hours to obtain a modifier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com