Inner frame paper folding device and system

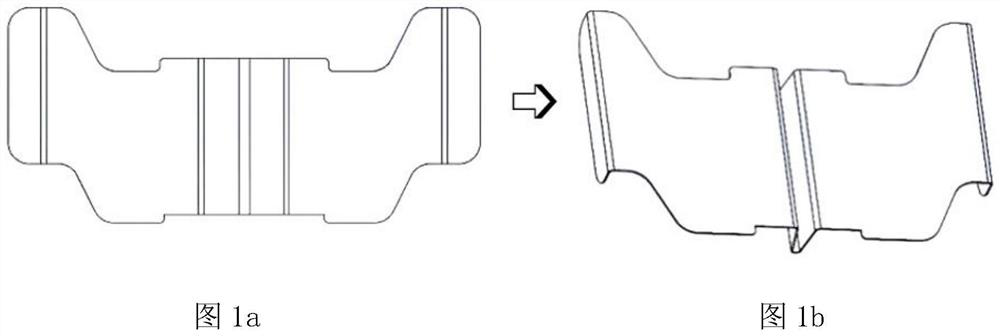

A folding device and folding system technology, which is applied in the direction of wrapping paper bending device, packaging, packaging cigarettes, etc., can solve the problems of easy occurrence and difficult control of folding, and achieve the effects of reducing downtime rate, improving folding quality and avoiding friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

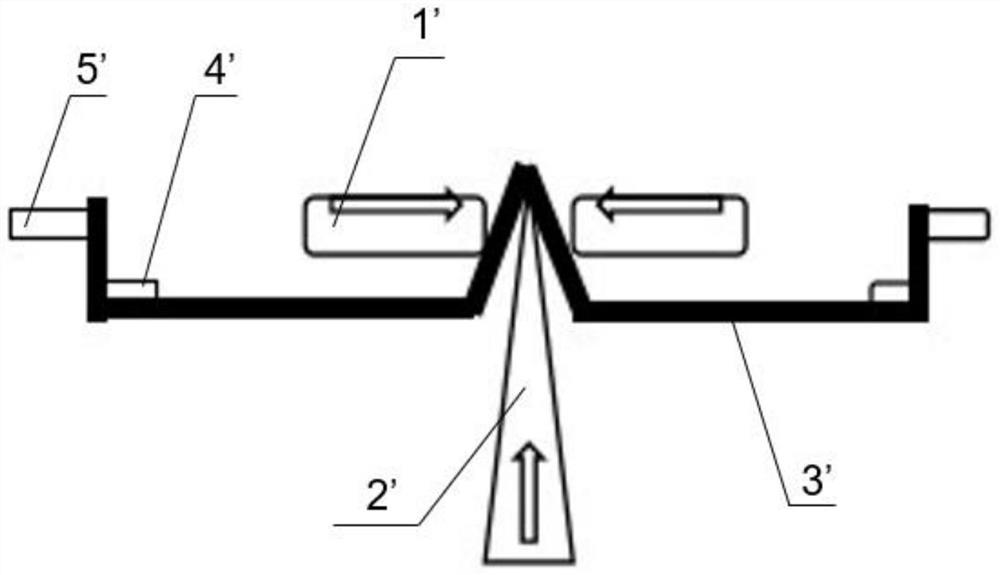

[0030] see Figure 4-6 , a kind of inner frame paper folding device, at least includes two grid plates 1 arranged parallel to each other, a support shaft 2, an upper runner 3, a belt 4, a pulley 5, a rotating shaft 17, a left support plate 6 arranged parallel to each other and Right support plate 10, following runner 7.

[0031] Specifically, a plurality of rotating shafts 17 are installed between the left support plate 6 and the right supporting plate 10, a plurality of lower runners 7 are installed side by side in the middle of the rotating shaft 17, the pulley 5 is installed at one end of the rotating shaft 17, and the belt 4 Set on all pulleys 5. The power is transmitted to the pulley through the drive pulley, or a drive pulley is also connected in the belt to provide power for the pulley of the belt conveyor. The support shaft 2 is installed between the left support plate 6 and the right support plate 10, one end of the two grid plates 1 is hinged in the middle of the s...

Embodiment 2

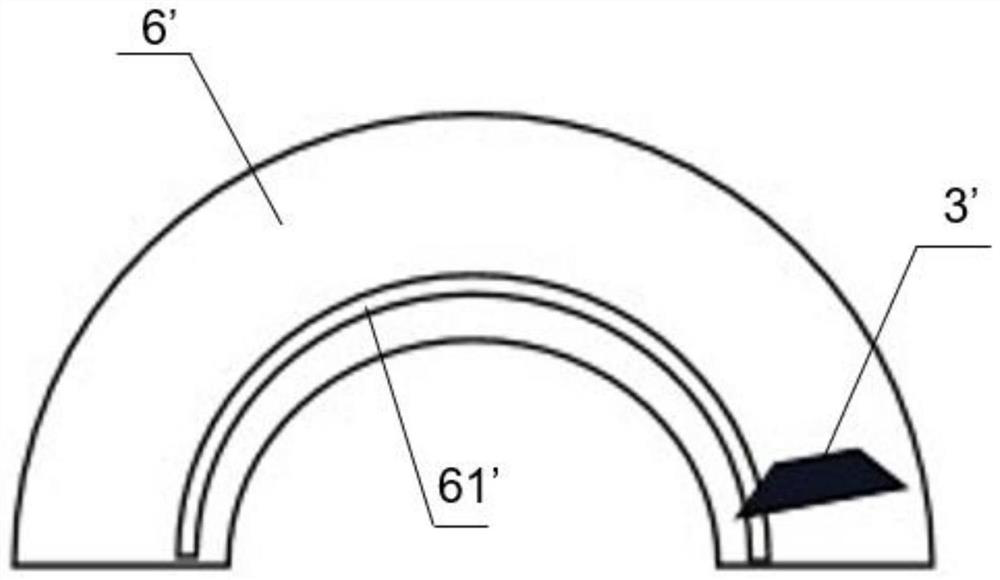

[0038]An inner frame paper folding system includes a semicircular conveying device and the inner frame paper folding device described in Embodiment 1. The semicircular conveying device includes two parallel supports 20, two rows of rollers 18 arranged in an arc between the two supports, and two conveyor belts 19 sleeved on one row of rollers 18 respectively. The middle part of the inner frame paper 8 is conveyed to the next station by two conveyer belts 19, and due to the clamping of the two conveyer belts 19, the inner frame paper 8 is completely folded in place.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com