Single-planet-row electric driving system based on synchronizer gear shifting and control method of single-planet-row electric driving system

A drive system and synchronizer technology, which is applied in electric vehicles, control drives, control devices, etc., can solve the problems of poor smoothness and shifting quality, large space occupied by parallel shafts, and complex transmission systems, so as to reduce the shifting force. , the effect of reducing shift shock and compact drive system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be described in further detail in conjunction with the following, so that those skilled in the art can implement it with reference to the description.

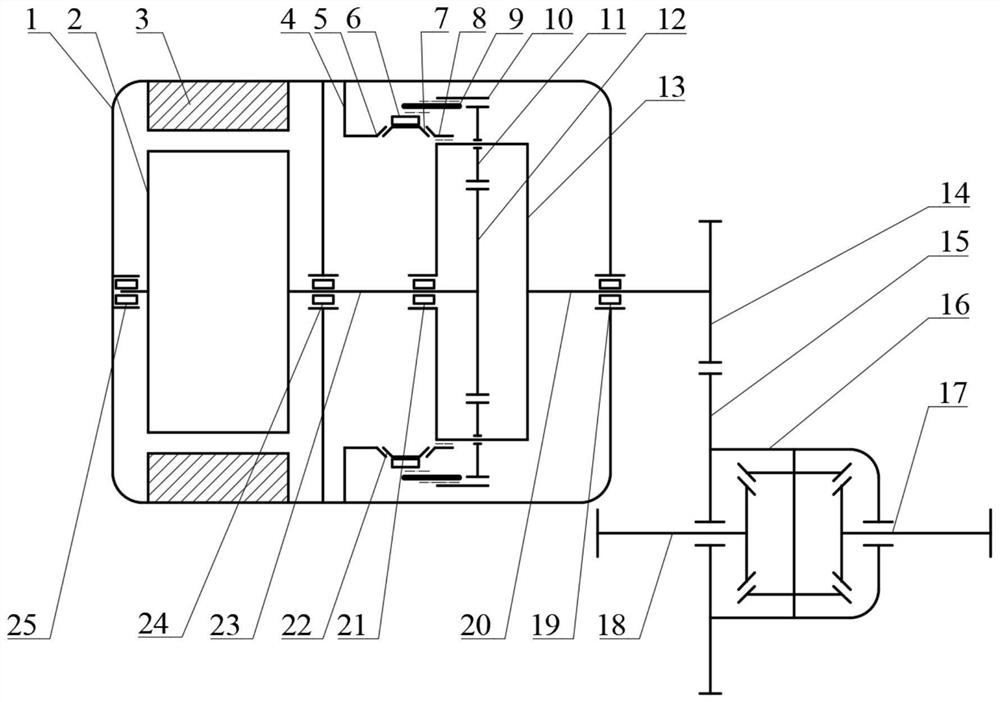

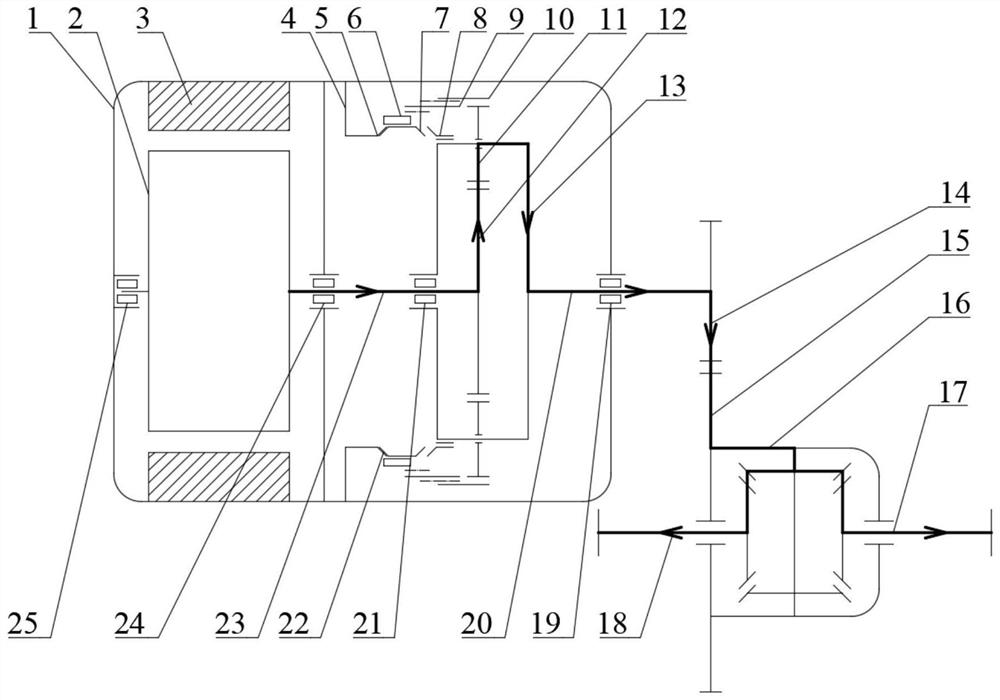

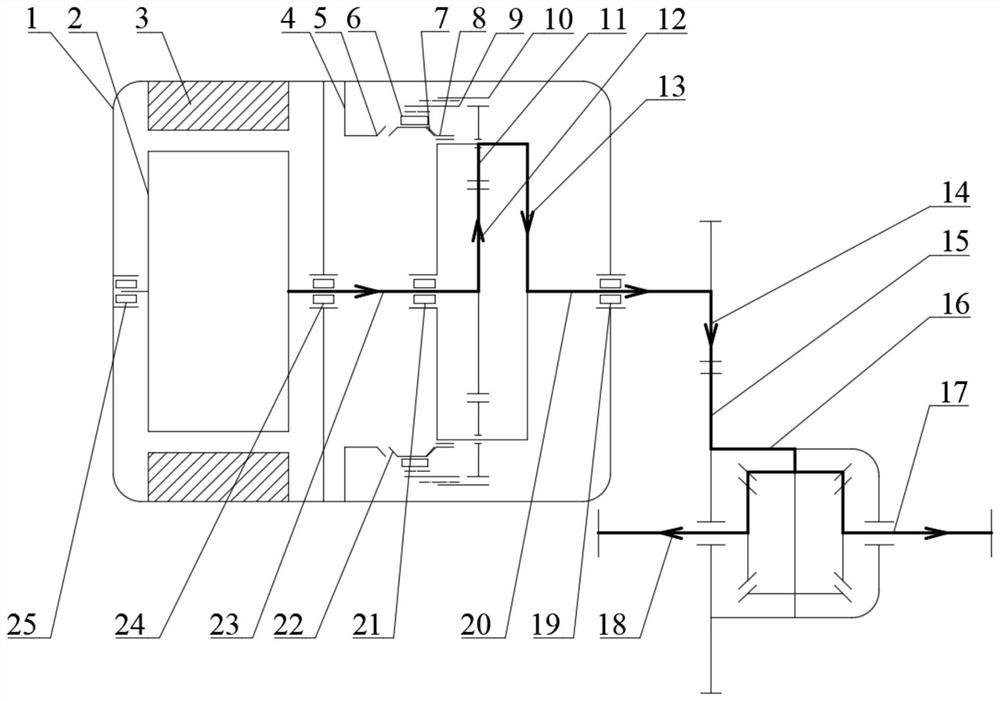

[0069] Such as figure 1 As shown, the present invention provides a single planetary electric drive system based on synchronizer shifting, which specifically includes: 1. Housing, 2. Rotor, 3. Stator, 4. Low-speed gear diaphragm, 5. Low-speed gear cone Hub, 6, sliding sleeve, 7, direct gear synchronous ring, 8 direct gear cone hub, 9, ring gear, 10, planetary gear ring gear, 11, planetary gear, 12, sun gear, 13, planet carrier, 14, Output gear, 15, differential gear, 16, differential assembly, 17, right half shaft, 18, left half shaft, 19, bearing, 20, transmission output shaft, 21, bearing, 22, low gear synchronous ring , 23, drive motor output shaft, 24, bearing, 25, bearing.

[0070] The pure electric vehicle electric drive system mainly includes a drive motor and a transmission part. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com