Lamp holder reflective bowl assembling device and assembling method

A technology for assembling device and reflective bowl, which is applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of easily damaged reflective bowl structure, high scrap rate of finished products, difficult to promote and use, etc., so as to avoid deformation and scrap, assembly quality Stable and ensure the effect of assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

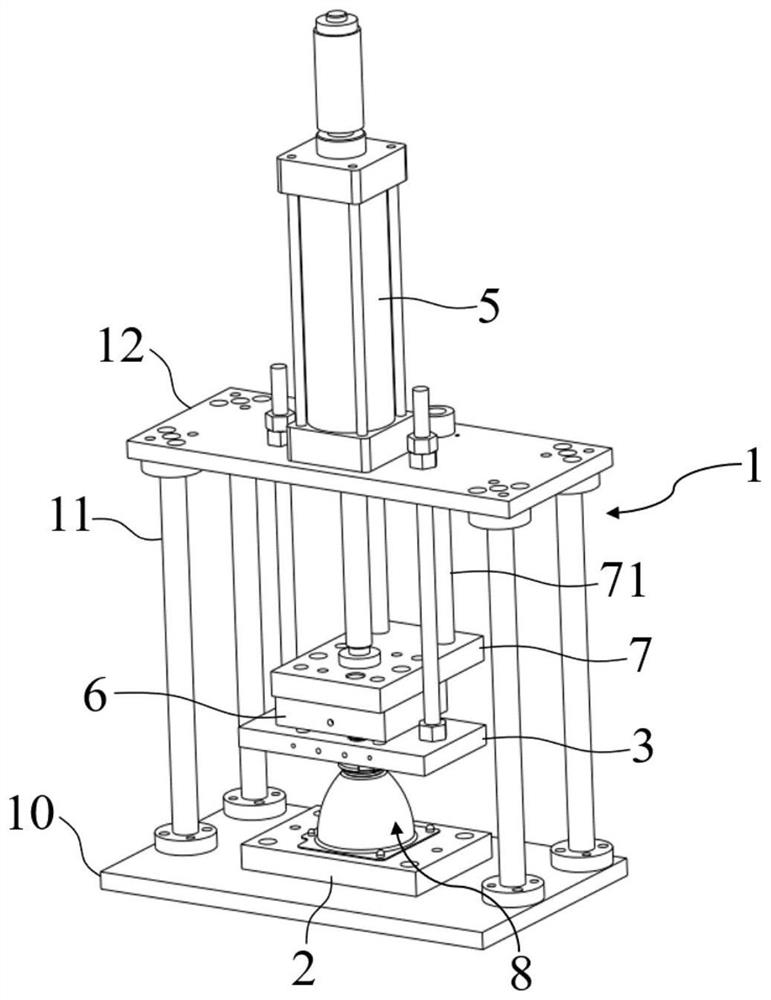

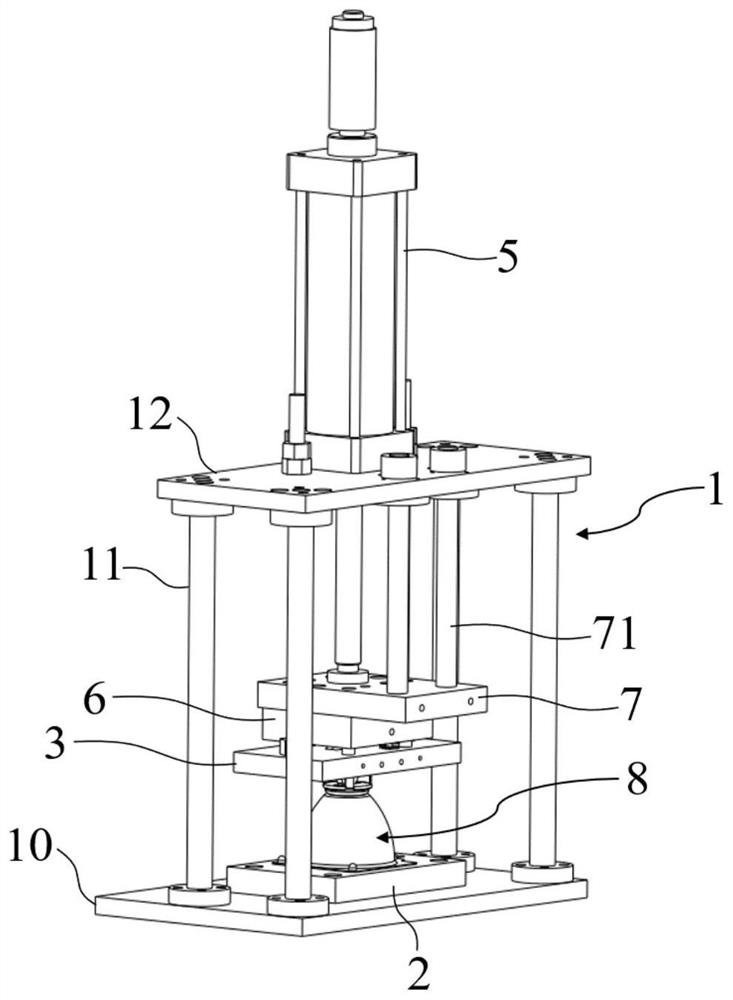

[0068] The lamp holder reflective bowl assembly device of this embodiment includes:

[0069] pedestal 1;

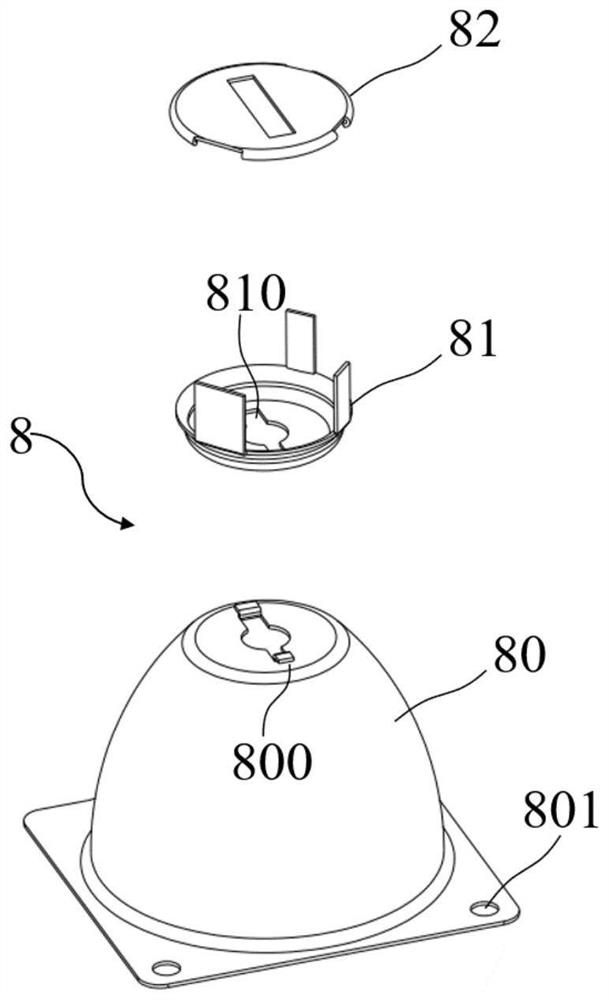

[0070] The mounting plate 2 is placed horizontally on the bottom of the base frame 1, and the lamp housing 8 to be assembled is placed on the mounting plate 2;

[0071] The fixed plate 3 is horizontally fixed above the mounting plate 2;

[0072] Assembly mechanism 4, which includes two rotary claws with the same shape and arranged symmetrically to each other. The rotary claws include an inclined part 40, a positioning part 41 and a working part 42 from top to bottom. A waist-shaped hole 400 is penetrated on the inclined part 40, and the length direction of the waist-shaped hole 400 is along the length direction of the inclined part 40. A fixing hole 410 is penetrated on the positioning part 41, and the surfaces of the two working parts 42 facing away from each other are formed by depressions. With card slot 420,

[0073] Assembly mechanism 4 also comprises pin one 43 a...

Embodiment 2

[0080] The reflective bowl assembly device of the lamp holder in this embodiment is further improved on the basis of Embodiment 1, and the base frame 1 includes:

[0081] base plate 10, which is arranged horizontally;

[0082] Upright column 11, it has several, vertical arrangement, one end of upright column 11 is fixedly connected with bottom plate 10 top surface;

[0083] The horizontal plate 12 is arranged horizontally and fixed on the other end of the column 11;

[0084] The driving mechanism 5 is a cylinder, which is fixed on the horizontal plate 12, and the telescopic rod 50 of the cylinder stretches out from the bottom of the horizontal plate 12;

[0085] The mounting plate 2 is fixed on the top surface of the base plate 10 , and the top surface of the mounting plate 2 protrudes upwards to form a mounting pile 20 . The shape and position of the mounting pile 20 matches the shape and position of the lamp mounting hole 801 .

[0086] Such as Figure 4 with Figure 5 A...

Embodiment 3

[0088] The reflective bowl assembly device for the lamp base of this embodiment is further improved on the basis of Embodiments 1 and 2. The top surface of the installation plate 2 is provided with a support column 21, and the bottom surface of the support column 21 is detachable from the top surface of the installation plate 2. Connected, the top surface of the support column 21 abuts against the rear end of the inner wall of the reflective bowl 80 .

[0089] Such as Figure 4 with Figure 5 As shown, the main function of the support column 21 is to be arranged inside the reflective bowl 80 during assembly. The bottom of the support column 21 is in contact with the mounting plate 2, and the top is in contact with the tail end of the inner wall of the reflective bowl 80. When assembling, pass The support column 21 supports the reflective bowl 80, which can ensure that the reflective bowl 80 will not be subjected to downward pressure, and avoid the situation that the reflectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com