Preparation method for ultra-black coating with high ultraviolet band absorption

A technology of ultraviolet band and black coating, applied in coating, metal material coating process, alkali metal silicate coating, etc., can solve the problem of low absorption rate in ultraviolet band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

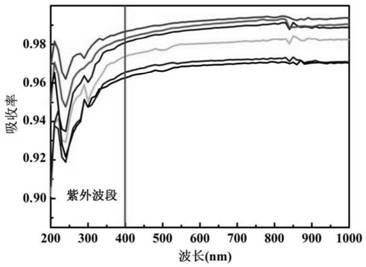

[0026] Embodiment 1: A kind of preparation method of the ultra-black coating with ultraviolet band high absorption is realized through the following steps in the present embodiment:

[0027] Take 100g spray liquid as an example:

[0028] Step 1. After mixing 30g of potassium silicate, 70mL of water and 0.2g of additive Tego 280, add zirconium beads with a diameter of 1mm. The amount of zirconium beads is one-third of the liquid volume. Stir and disperse evenly and divide into five equal parts. Separate and then add different mass fractions of high-performance carbon black, ultrasonically disperse for 3 minutes, continue to stir for 3 hours, filter through a filter cloth, stir slowly (500rpm) until the suspension is stable and does not precipitate (it takes 0.5h), and spray coatings with different concentrations are obtained. Liquid, the mass fraction of carbon black in the spraying liquid is 0.5%, 0.4%, 0.3%, 0.2%, 0.1% respectively;

[0029] Step 2, and then put into the spr...

Embodiment 2

[0036] Embodiment 2: A kind of preparation method of the ultra-black coating with ultraviolet band high absorption is realized through the following steps in the present embodiment:

[0037] Take 100g spray liquid as an example:

[0038] Step 1. After mixing 30g of potassium silicate, 70mL of water and 0.2g of additive Tego 280, add zirconium beads with a diameter of 1mm. The amount of zirconium beads is one-third of the liquid volume. Stir and disperse evenly and divide into five equal parts. Separate and then add different mass fractions of high-performance carbon black, ultrasonically disperse for 5 minutes, continue to stir for 3 hours, filter through a filter cloth, stir slowly (500rpm) until the suspension is stable and does not precipitate (it takes 0.5h), and spray coatings with different concentrations are obtained. Liquid, the mass fraction of carbon black in the spraying liquid is 1.0%, 0.8%, 0.6%, 0.4%, 0.2% respectively;

[0039] Step 2, and then put into the spr...

Embodiment 3

[0046] Embodiment 3: a kind of preparation method of the ultra-black coating with ultraviolet band high absorption in the present embodiment is realized through the following steps:

[0047] Take 100g spray liquid as an example:

[0048] Step 1. After mixing 30g of potassium silicate, 70mL of water and 0.2g of additive Tego 280, add zirconium beads with a diameter of 1mm. The amount of zirconium beads is one-third of the liquid volume. Stir and disperse evenly and divide into five equal parts. Separate and then add different mass fractions of high-performance carbon black, ultrasonically disperse for 4 minutes, continue to stir for 3 hours, filter through a filter cloth, stir slowly (400rpm) until the suspension is stable and does not precipitate (it takes 0.5h), and spray coatings with different concentrations are obtained. Liquid, the mass fraction of carbon black in the spraying liquid is 0.5%, 0.4%, 0.3%, 0.2%, 0.1% respectively;

[0049] Step 2, and then put into the spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com