Crack length measuring and calculating method based on curvature correction principle

A technology of crack length and curvature, which is applied in the field of fracture mechanical performance testing of metal materials, can solve the problems of identification and measurement, crack length cannot be accurately measured, and crack length linear relationship is poor, so as to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

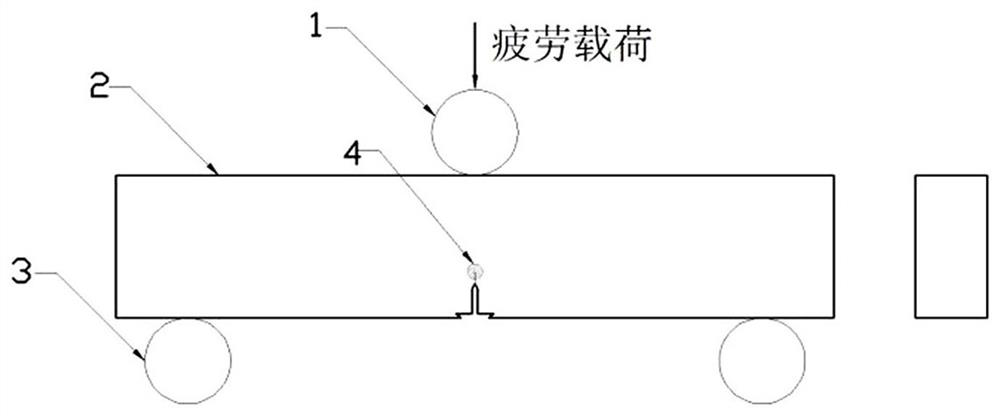

[0041] In this example, the sample material is X70 pipeline steel, the sample type is a three-point bending sample, the sample size thickness B is 28mm, the width W is 56mm, and the notch length is a nis 11.00mm, and the test span S is 224mm.

[0042] A method for measuring and calculating crack length based on the principle of curvature correction, comprising the following steps:

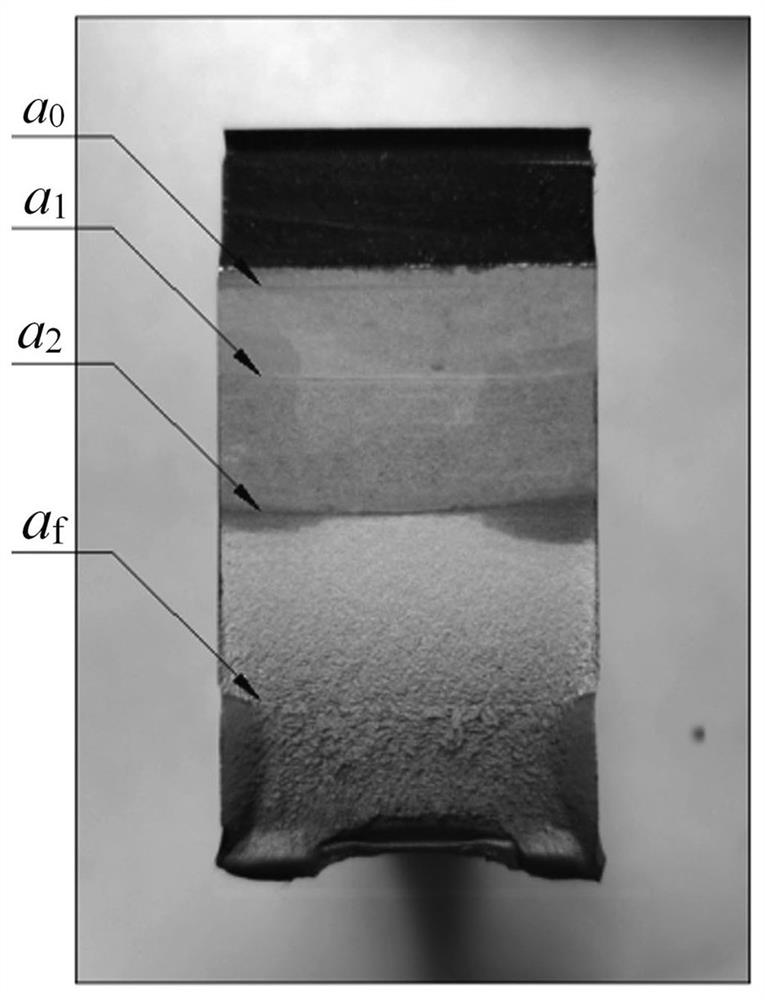

[0043] S1. Prefabricate cracks on the notched sample, and calculate the initial crack length a by the flexibility method 0 13.01mm, the coloring agent made by mixing absolute alcohol and coloring penetrating agent is rubbed on the crack tip from the side of the sample. Wherein, the volume ratio of the absolute alcohol to the colored penetrating agent is 8:1-5:1, and the colored penetrating agent adopts an organic solvent.

[0044] In the actual implementation, according to the state of the marked crack, the proportion of the coloring agent can be adjusted appropriately. When the coloring is not c...

Embodiment 2

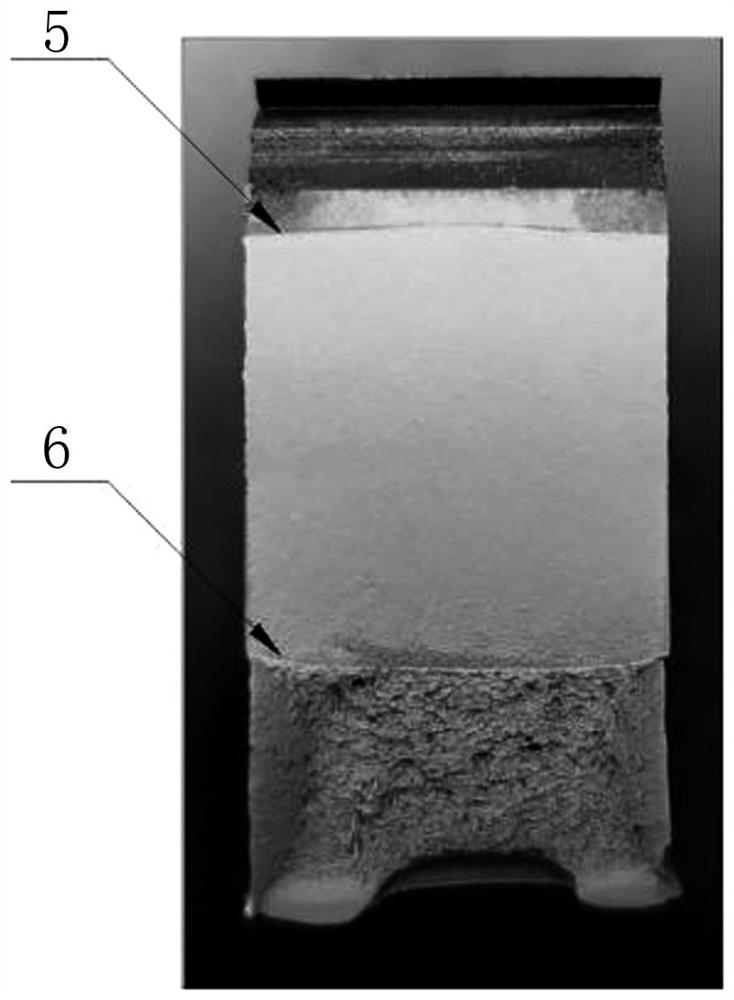

[0059] This embodiment is a specific application of the present invention in the crack growth rate test of metal materials. Taking the crack growth rate test of X70 pipeline steel material as an example below, the crack length measured and calculated by the flexibility method is corrected once by measuring the initial crack length and the final crack length, and the experiment proves the crack length based on the curvature correction principle described in the present invention The calculation method improves the accuracy of the test results.

[0060] 1. Test material: X70 pipeline steel.

[0061] 2. Test temperature: 23-25°C, ambient relative humidity: 40-50%.

[0062] 3. Sample type: three-point bending sample, sample size thickness B is 24mm, width W is 48mm, notch length is a n is 7.2mm, and the test span S is 240mm.

[0063] 4. Test method:

[0064] 1) Prefabrication of cracks on the notched specimen. The crack is prefabricated by the falling K method, and the final ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com