Improved structure of drum brake

A drum brake, a pair of technology, applied in the field of motorcycle and electric vehicle brake devices, can solve the problems of large vehicle braking sliding distance, easy wear of the brake cam, poor braking effect of drum brakes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

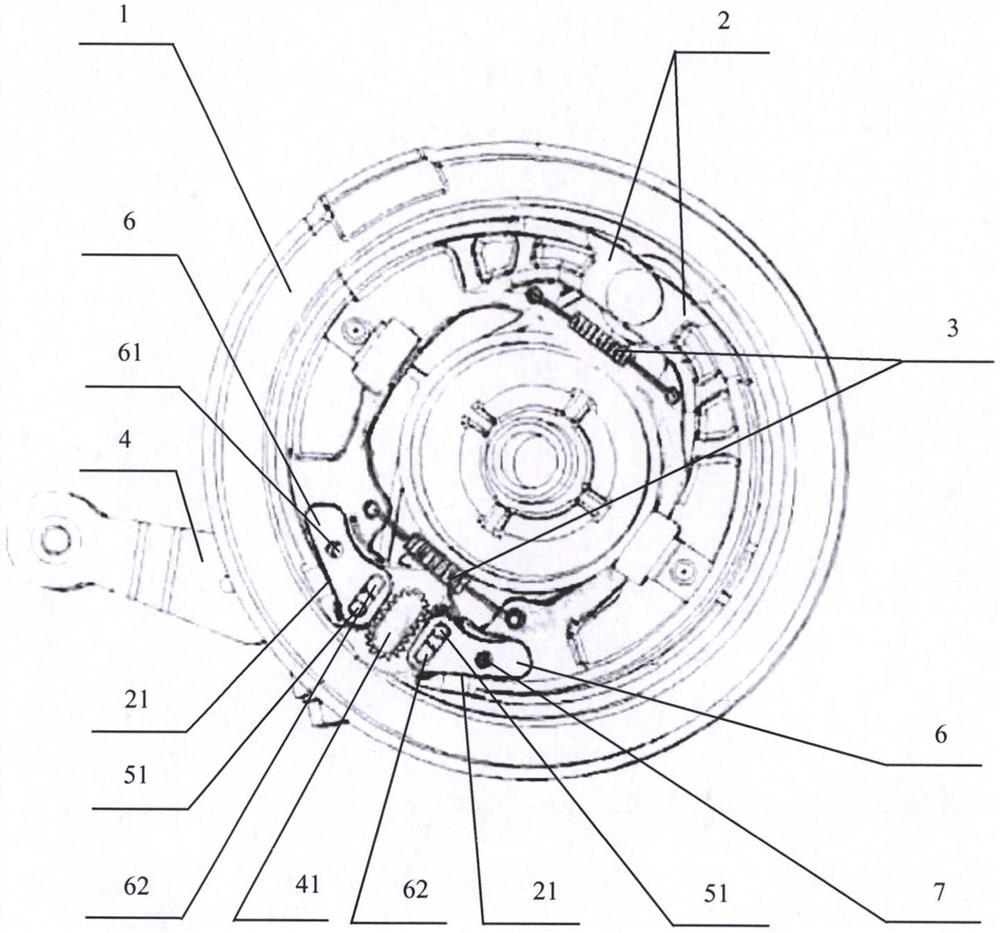

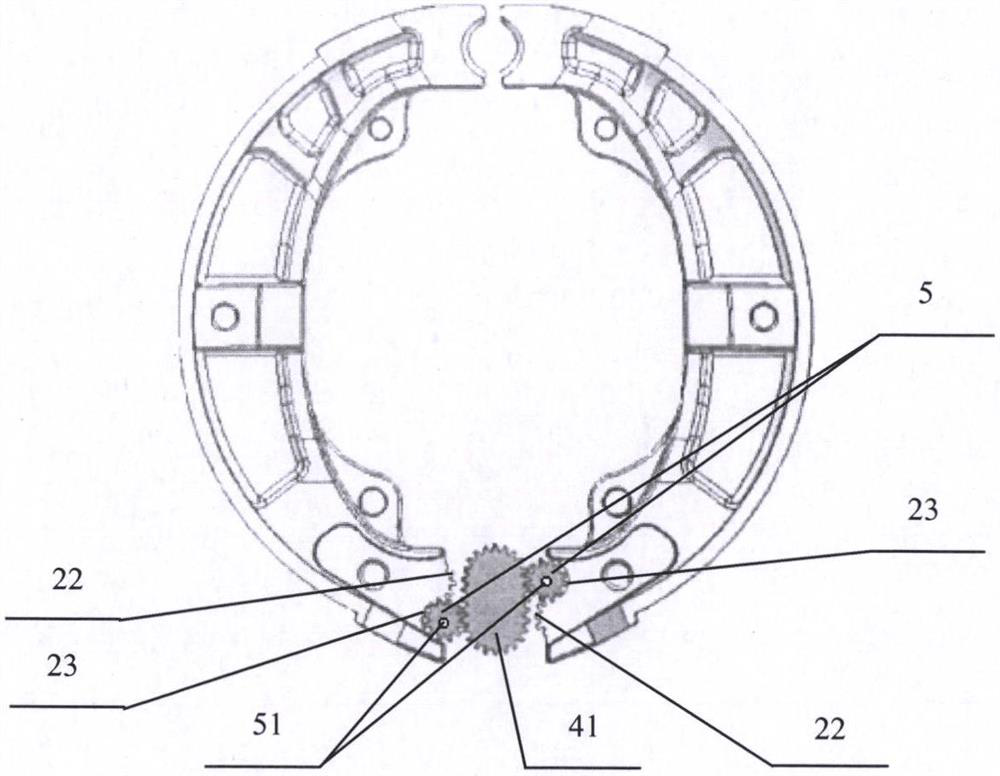

[0007] as attached figure 1 , attached figure 2 As shown, a pair of brake shoes (2) are installed in the casing (1), the elastic reset element (3) is connected between the brake shoes (2), and one end of the pair of brake shoes (2) is rotatably positioned on the casing In (1), a waist-shaped columnar brake gear (41) driven by the brake rocker arm assembly (4) is provided between the end gaps at the other end, and the waist-shaped columnar brake gear (41) is connected to the brake shoes (2) on both sides. ) between the end faces of a roller gear (5), the rivet (7) fixes the connecting piece (6) in the pit (21) of a pair of brake shoes (2), and the roller gear (5) The shaft (51) is installed in the waist-shaped hole (62) of the connecting piece (6) and can rotate and move therein. When the brake rocker arm assembly (4) drives the waist-shaped columnar brake gear (41) to rotate, the waist-shaped columnar brake wheel (41) drives the two roller gears (5) to rotate and move, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com