A sound-insulating assembled wall panel and its production method

A production method and assembly technology, applied in the direction of sound insulation, chemical instruments and methods, walls, etc., can solve the problems of poor sound insulation effect, affecting the life and health of residents, and difficult living experience of indoor residents, so as to reduce the penetration , reduce the transmission speed, good sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

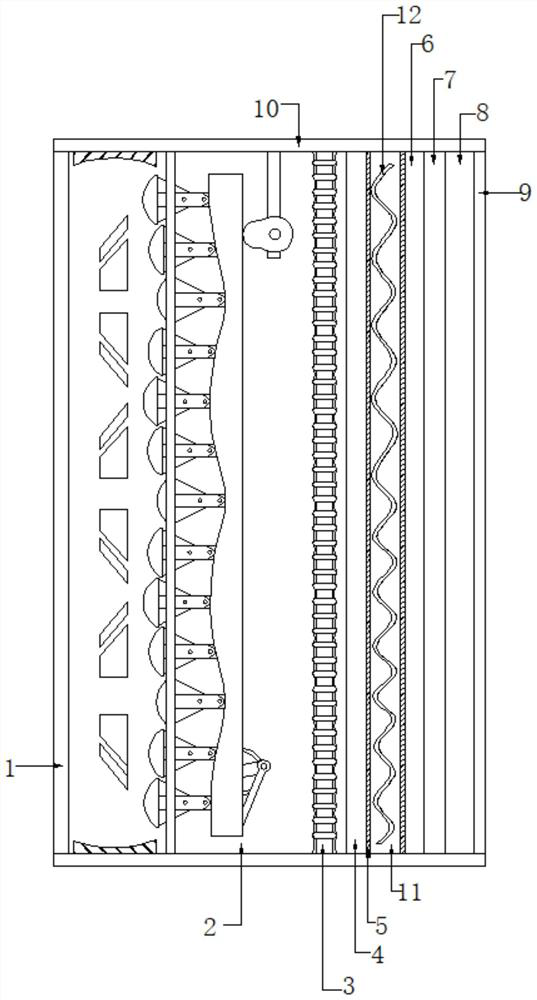

[0041] Such as Figure 1-3 displayed in:

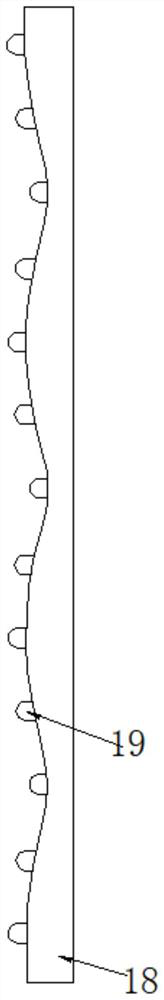

[0042] The invention provides a sound-insulating assembled wallboard, comprising an outer layer 1, a vacuum layer 2, a corrugated board 3, a drying layer 4, a waterproof layer 5, a moisture-proof layer 6, an insulating layer 7, a supporting surface layer 8, and an inner surface layer 9 And the pressing line 10, the inner side of the outer layer 1 is provided with the vacuum layer 2, the inner side of the vacuum layer 2 is provided with the corrugated board 3, the inner side of the corrugated board 3 is provided with the drying layer 4, the The inside of the drying layer 4 is provided with the waterproof layer 5, the inside of the waterproof layer 5 is provided with the moisture-proof layer 6, the inside of the moisture-proof layer 6 is provided with the heat-insulation layer 7, and the inside of the insulation layer 7 is provided with the A supporting surface layer 8, the inner surface layer 9 is provided on the inner side of the sup...

Embodiment 2

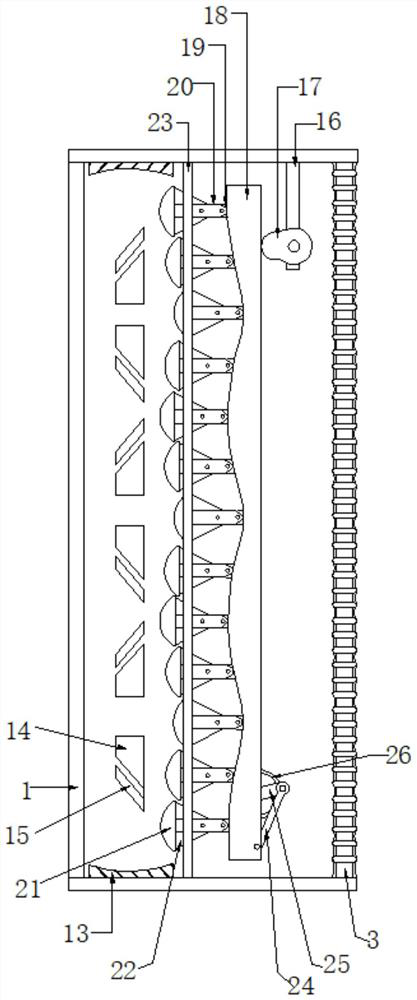

[0045] Such as Figure 4 displayed in:

[0046] A method for producing a sound-insulating prefabricated wall panel, comprising the following steps:

[0047] S101: Pre-press the plate to form a wave pattern, and process a thin plate into an S-shaped wave-like return plate;

[0048] S103: Press and fix the corrugated board, dry layer, waterproof layer, moisture-proof layer, thermal insulation layer, support surface layer and inner surface layer in advance, and at the same time use the pressure line to seal the edge, and the pre-formed return board set in the waterproof layer;

[0049] S105: Manufacture the primary mirror, secondary mirror, secondary mirror base and noise reduction mechanism: among them, two primary mirrors are made, and the primary mirror is pre-cut into a concave groove-shaped lens on one side, and the secondary mirror is made to be inclined The strip-shaped double-sided lens, the auxiliary mirror base is cut into a slope that is the same as and conforms to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com