Road reflective energy-saving pavement structure in tunnel and paving method thereof

A technology for pavement structures and tunnels, which is applied to road reflective and energy-saving pavement structures in tunnels and their paving fields, can solve problems such as damage to the pavement structure, poor light reflection effect of white gravel, attenuation of road performance, etc., so as to reduce illumination Output, improve light reflection ability, improve the effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

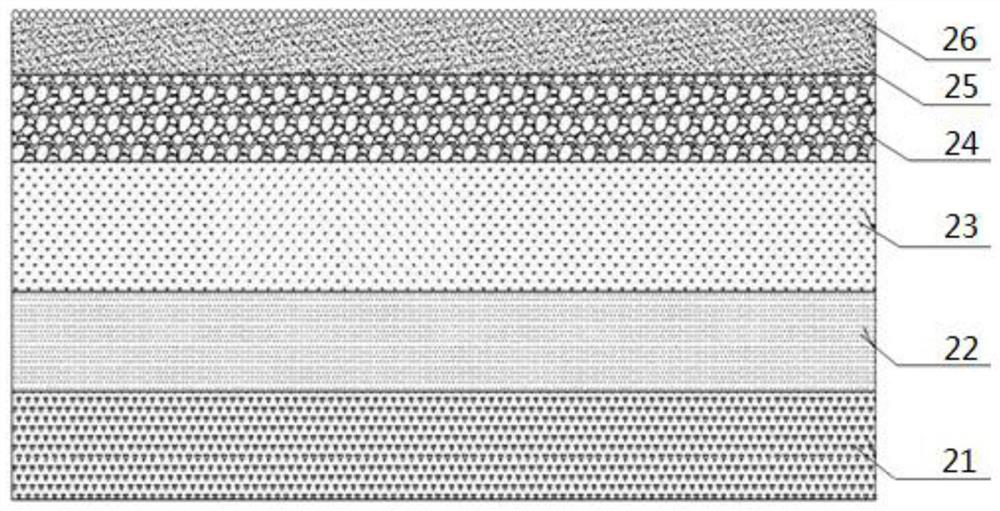

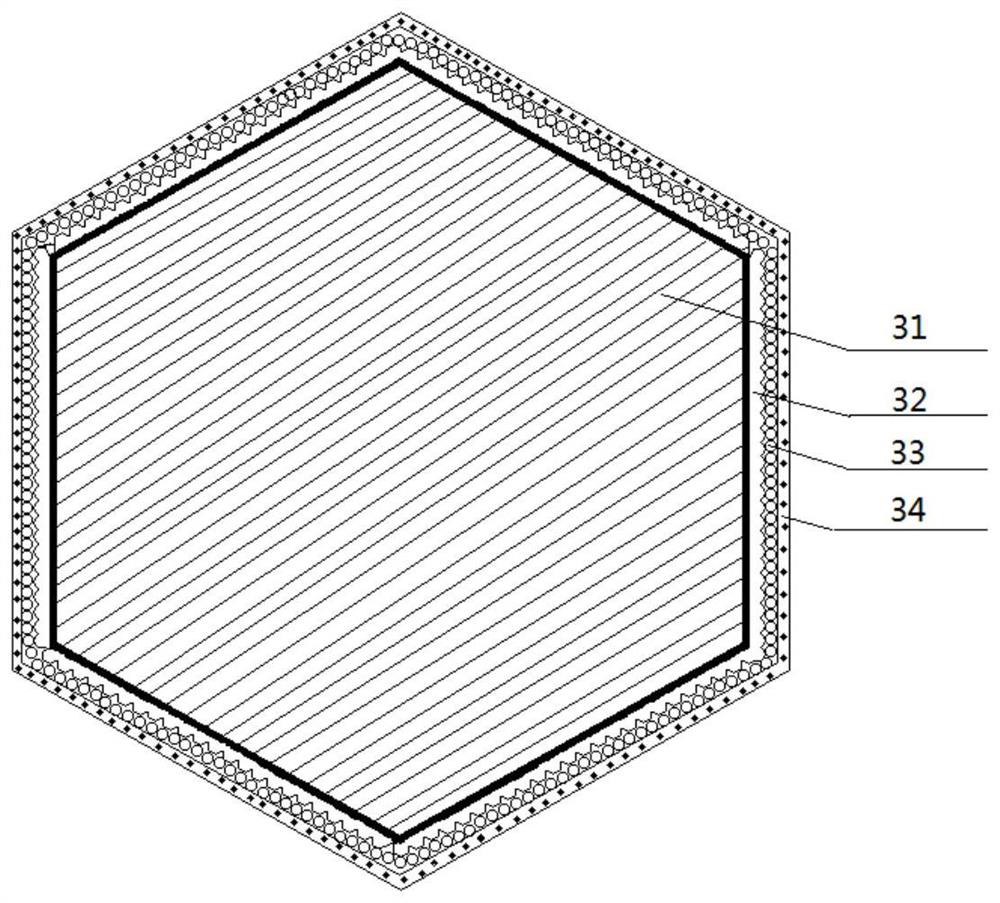

[0060] Such as figure 1 The reflective and energy-saving pavement structure of a road in a tunnel is shown, including an original soil layer 21, a sandstone layer 22 and a gravel layer 23 laid sequentially from bottom to top, and a rough asphalt concrete layer 24 is laid on the gravel layer 23, A fine asphalt concrete layer 25 is laid on the rough asphalt concrete layer 24, and a reflective layer 26 is laid on the fine asphalt concrete layer 25. The reflective layer 26 is composed of several white ceramic particles with the same shape and particle size, such as figure 2 As shown, the white ceramic particles include a green body 31, the green body 31 has a multi-rhombic surface, a texture layer 32 is formed on the multi-rhombic surface, the surface of the texture layer 32 is covered with a reflective layer 33, and the reflective The surface of layer 33 is covered with a transparent protective layer 34 .

[0061] In this embodiment, the white ceramic particles can be fully emb...

Embodiment 2

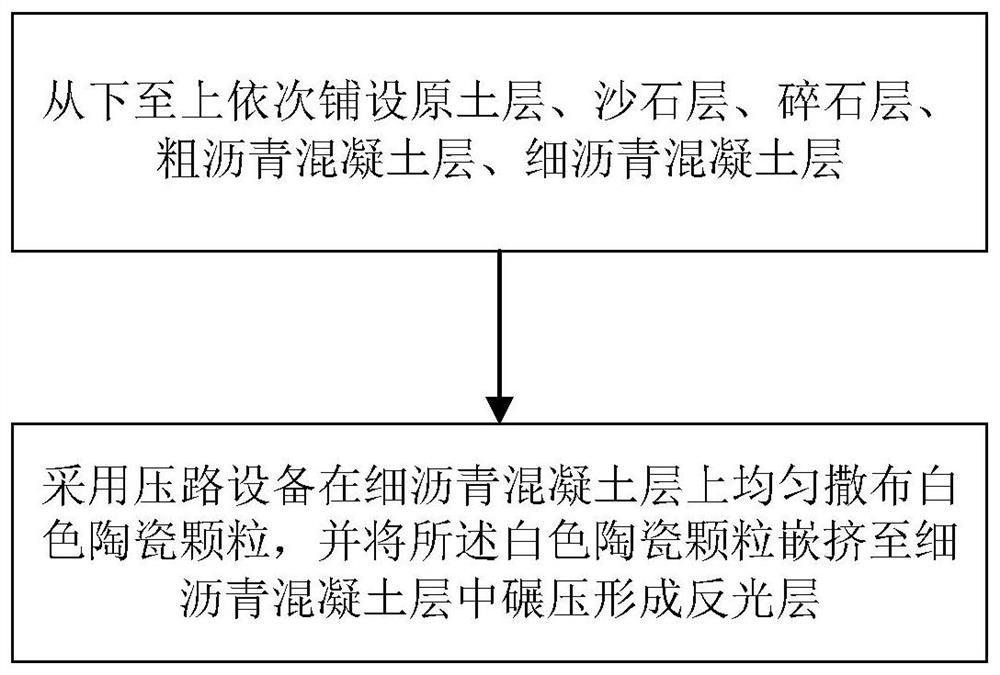

[0067] Such as image 3 A method for paving a reflective energy-saving pavement structure of a highway in a tunnel is used for paving any of the above-mentioned pavement structures, and the method includes the following steps:

[0068] Lay the original soil layer 21, sandstone layer 22, gravel layer 23, rough asphalt concrete layer 24, and fine asphalt concrete layer 25 sequentially from bottom to top;

[0069] The road rolling equipment is used to uniformly spread white ceramic particles on the fine asphalt concrete layer 25 , and insert and extrude the white ceramic particles into the fine asphalt concrete layer 25 for rolling to form the reflective layer 26 .

[0070] In this embodiment, after the original soil layer, sandstone layer, crushed stone layer, rough asphalt concrete layer, and fine asphalt concrete layer are paved in sequence, white ceramic particles are spread on the fine asphalt concrete layer by road rollers, and the The rollers of the road equipment roll th...

Embodiment 3

[0072] On the basis of the above examples, if Figure 4 to Figure 10 A road rolling device is shown, the road rolling device includes a fuselage 1, the fuselage 1 is provided with a blanking box 10 for spreading white ceramic particles, and a first wheel frame 2 and a second wheel frame 3 , the first roller frame 2 is provided with a first roller 4, the second roller frame 3 is provided with a second roller 5, and the first roller 4 is connected with a The first moving frame 7, the first cover plate 71 is arranged on the first moving frame 7, the second rolling roller 5 is connected with the second moving frame 8 through the second transmission mechanism, the second moving frame 8 A second cover plate 81 is arranged on it, and the bottom end of the discharge box 10 is closed when the first cover plate 71 and the second cover plate 81 abut against each other. The first rolling roller 4 and the second rolling roller 5 Drive the first moving frame 7 and the second moving frame 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com