Device for treating bulk solid wastes through coordination of pyrolyzing furnace and plasma gasification

A solid waste and coordinated treatment technology, which is applied in the direction of gasification process, combustible gas production, petroleum industry, etc., can solve the problems of inability to quickly discharge waste slag in the furnace, reduce the efficiency of solid waste treatment, and endanger the health of staff, etc., to achieve extended The effect of using time, improving cleanliness, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

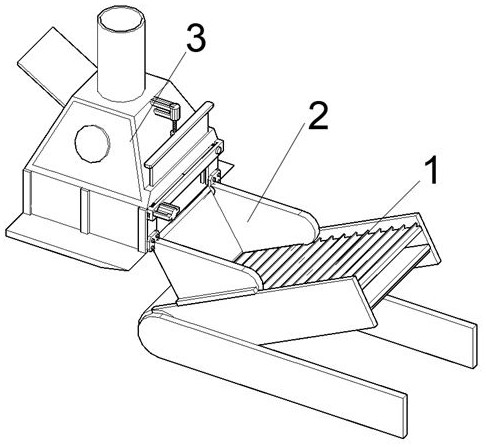

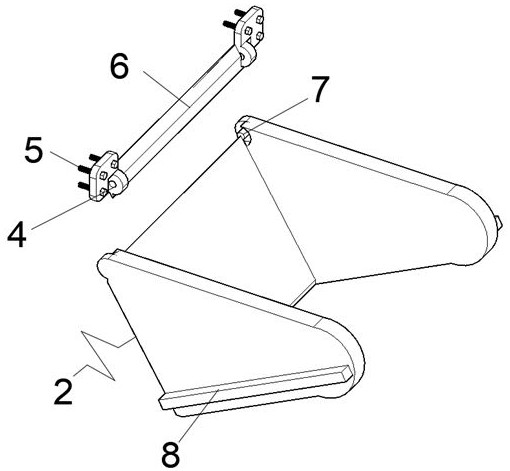

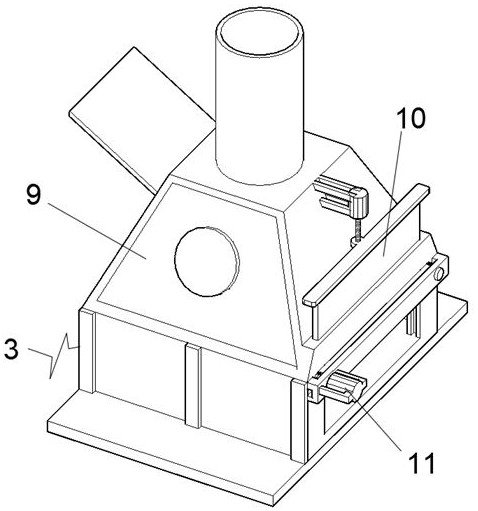

[0032] see Figure 1-2, an embodiment provided by the present invention: a pyrolysis furnace and plasma gasification coordinated treatment of bulk solid waste equipment, including a waste residue conveyor belt 1, a waste residue guide plate 2 and a solid waste pyrolysis device 3, the bottom of the waste residue guide plate 2 The end is clamped on the upper surface of the waste slag conveyor belt 1, the top of the waste slag guide plate 2 is rotatably connected to the center of the bottom edge side of the solid waste pyrolysis device 3, and the bottom edges of both sides of the waste slag guide plate 2 are symmetrically fixedly connected with snap-in plates 8. The inner surface on both sides of the top edge of the waste guide plate 2 is symmetrically fixed to the limit shaft 7, and the outer surface of the limit shaft 7 is rotatably fitted with a positioning connecting plate 6, and the side edges of the two ends of the positioning connecting plate 6 are symmetrically fixed Conn...

Embodiment 2

[0041] On the basis of Example 1, such as Figure 7-8 As shown, the inside of the slag scraper 23 is fixedly installed with a limit cover plate 28, and the bottom surface of the limit cover plate 28 is provided with a limit chute 25, and the inside of the limit chute 25 is slidably equipped with a waste scraper 29, and the limit cover plate The first threaded hole 26 is symmetrically opened on the upper edge of both ends of the side surface of 28, and the center of the side surface of the limiting sleeve plate 28 is provided with a limited slideway 27. , the outer surface of the plug rod 30 is movably sleeved with a return spring 32, and the upper center of the two sides of the waste scraper 29 is symmetrically fixedly connected with the limit block 31, and the waste scraper 29 is connected to the limit block 31 by the upper center of the side surface. The limit slideway 27 inside the side of the position cover plate 28 is slidably engaged, the limit chute 25 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com