Method for preparing lobetyolin, atractylenolide III and syringin from codonopsis pilosula based on PRE-HPLC

A technology of tangshenoside and atractylodes lactone, which is applied in chemical instruments and methods, preparation of sugar derivatives, and resistance to vector-borne diseases, etc., can solve the problems of large consumption of reagents, cumbersome process steps, and single separation components, and achieve The effect of improving efficiency, simple process and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing tangshenoside, atractyllide III and syringin from Radix Codonopsis based on PRE-HPLC, comprising the following steps:

[0029] (1) Medicinal material extraction: Take 100 g of Codonopsis pilosula, crush it, add 12 times the volume of 65% ethanol solution, 1200 mL each time, 400 W ultrasonic extraction for 60 min, and extract 3 times in total. After the extraction, coarse filter, collect and combine the filtrates.

[0030] (2) Concentration and drying: the above extract was concentrated and dried under reduced pressure at 45° C. to obtain 9.9 g of Codonopsis pilosula crude extract.

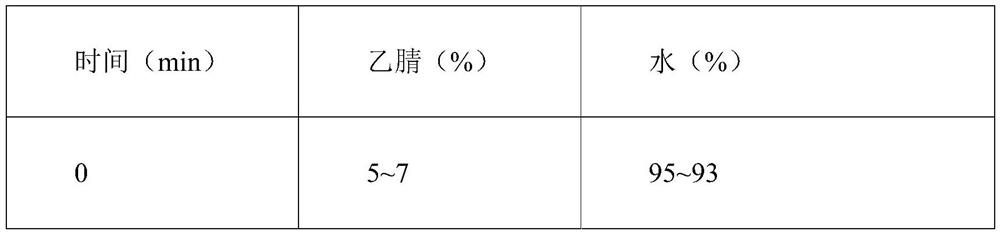

[0031] (3) Preparation and purification: take an appropriate amount of dried Codonopsis pilosula extract and add 100 times the amount of 70% ethanol solution to ultrasonically dissolve, then pass through a 0.22 μm microporous membrane to obtain the sample to be prepared, and finally separate and prepare by preparing the liquid phase, chromatographic conditions For: the...

Embodiment 2

[0037] A method for preparing tangshenoside, atractyllide III and syringin from Radix Codonopsis based on PRE-HPLC, comprising the following steps:

[0038] (1) Medicinal material extraction: Take 100 g of Codonopsis pilosula, crush it, add 14 times the volume of 70% ethanol solution, 1400 mL each time, 450W ultrasonic extraction for 45 min, and extract 3 times in total. After the extraction, coarse filter, collect and combine the filtrates.

[0039] (2) Concentration and drying: the above extract was concentrated and dried under reduced pressure at 60° C. to obtain 10.4 g of Codonopsis pilosula crude extract.

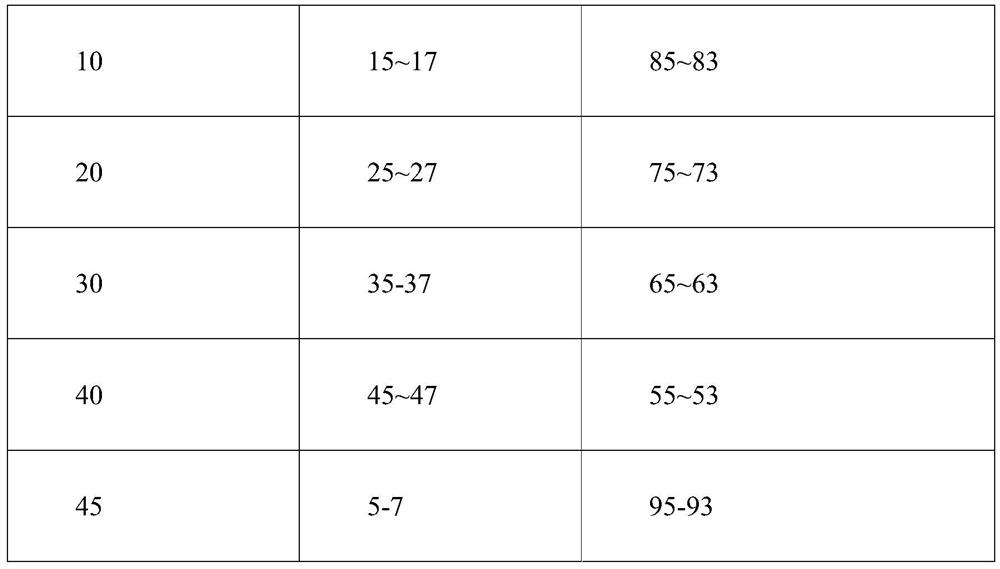

[0040] (3) Preparation and purification: take an appropriate amount of dried Codonopsis pilosula extract and add 150 times the amount of 65% ethanol solution to ultrasonically dissolve, then pass through a 0.22 μm microporous membrane to obtain the sample to be prepared, and finally separate and prepare by preparing the liquid phase, chromatographic conditions For: the...

Embodiment 3

[0046] A method for preparing tangshenoside, atractyllide III and syringin from Radix Codonopsis based on PRE-HPLC, comprising the following steps:

[0047] (1) Medicinal material extraction: Take 100 g of Codonopsis pilosula, crush it, add 15 times the volume of 75% ethanol solution, 1500 mL each time, 500 W ultrasonic extraction for 60 min, and extract 3 times in total. After the extraction, coarse filter, collect and combine the filtrates.

[0048] (2) Concentration and drying: the above extract was concentrated and dried under reduced pressure at 50° C. to obtain 10.7 g of Codonopsis pilosula crude extract.

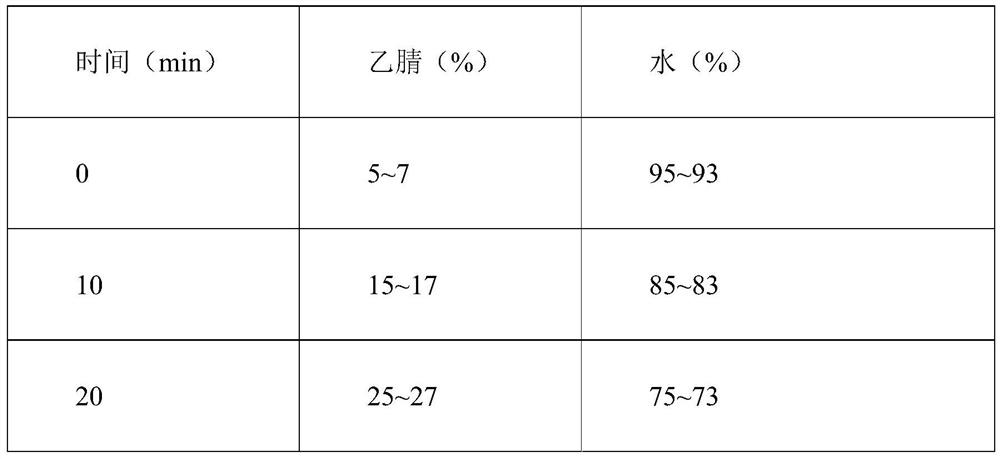

[0049] (3) Preparation and purification: take an appropriate amount of dried Codonopsis pilosula extract and add 200 times the amount of 75% ethanol solution to ultrasonically dissolve, then pass through a 0.22 μm microporous membrane to obtain the sample to be prepared, and finally separate and prepare by preparing the liquid phase, chromatographic conditions For: th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com