Compound A2, preparation method thereof and application of compound A2 as pranoprofen impurity

A compound and quality technology, applied in organic chemistry and other directions, can solve problems such as difficult quality of pranoprofen, and achieve the effect of high purity, high application value and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

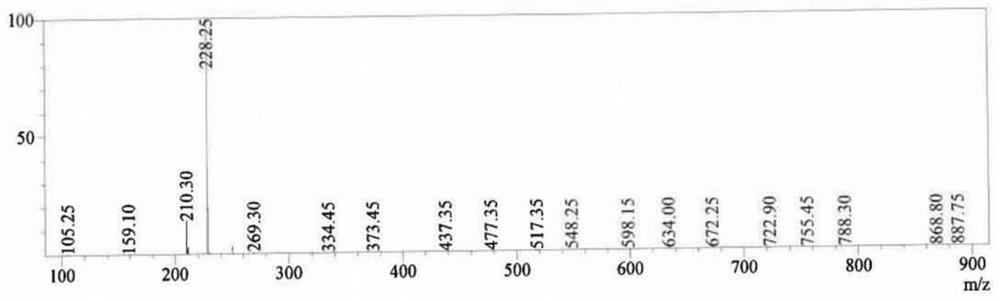

Examples

Embodiment 1

[0029] A preparation method of compound A2, the reaction equation is as follows:

[0030]

[0031] Specific steps include:

[0032] (1) Add 30mL carbon tetrachloride, 0.1g azobisisobutyronitrile, 2.11g compound B in sequence in the reactor, add dropwise the solution formed by 1.6g bromine and 10mL carbon tetrachloride;

[0033] (2) After the reaction is over, wash the reaction solution successively with 20 mL of 10% sodium bisulfite aqueous solution and 20 mL of distilled water, separate the sodium bisulfite aqueous layer, and concentrate the solvent carbon tetrachloride to dryness to obtain a concentrate D;

[0034] (3) Add 20 mL of distilled water and 1 mL of 10% sodium hydroxide solution to the concentrate D obtained in step (2), stir overnight, extract the water layer with 10 mL of ether three times, combine the extracts, and concentrate the ether to dryness below 10°C. , to obtain concentrate E;

[0035] (4) Purify with a silica gel column with a diameter of 1 cm an...

Embodiment 2

[0038] A preparation method of compound A2, the reaction equation is as follows:

[0039]

[0040] Specific steps include:

[0041] (1) Add 30 mL of carbon tetrachloride, 0.076 g of azobisisobutyronitrile, 1.6 g of compound B in sequence in the reactor, and add dropwise the solution formed by 1.0 g of bromine and 10 mL of carbon tetrachloride;

[0042] (2) After the reaction is over, wash the reaction solution successively with 20 mL of 10% sodium bisulfite aqueous solution and 20 mL of distilled water, separate the sodium bisulfite aqueous layer, and concentrate the solvent carbon tetrachloride to dryness to obtain a concentrate D;

[0043] (3) Add 20 mL of distilled water and 0.8 mL of 5% sodium hydroxide solution to the concentrate D obtained in step (2), stir overnight, extract the water layer three times with 10 mL of ether, combine the extracts, and concentrate the ether below 10°C to dry to obtain concentrate E;

[0044] (4) Purify with a silica gel column with a ...

Embodiment 3

[0047] A preparation method of compound A2, the reaction equation is as follows:

[0048]

[0049] Specific steps include:

[0050] (1) Add 30mL carbon tetrachloride, 0.11g azobisisobutyronitrile, 2.4g compound B in sequence in the reactor, add dropwise the solution formed by 2.0g bromine and 10mL carbon tetrachloride;

[0051] (2) After the reaction is over, wash the reaction solution successively with 20 mL of 10% sodium bisulfite aqueous solution and 20 mL of distilled water, separate the sodium bisulfite aqueous layer, and concentrate the solvent carbon tetrachloride to dryness to obtain a concentrate D;

[0052] (3) Add 20mL of distilled water and 1.1mL of 1.1mL sodium hydroxide solution with a mass fraction of 15% to the concentrate D obtained in step (2), stir overnight, extract the water layer with 10mL ether for three times, combine the extracts, and concentrate the ether below 10°C to dry to obtain concentrate E;

[0053] (4) Purify with a silica gel column wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com