High-strength and high-porosity thermal-insulation ceramsite prepared by compounding electrolytic manganese residues with coal-series wastes and preparation method thereof

A technology of electrolytic manganese slag and porosity, which is applied to ceramic products, clay products, and other household utensils, etc. It can solve the problems that sulfide will corrode grass roots, complicated operation steps, and lack of access to farmers, so as to improve the water resource environment Pollution problem, simple production process, effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

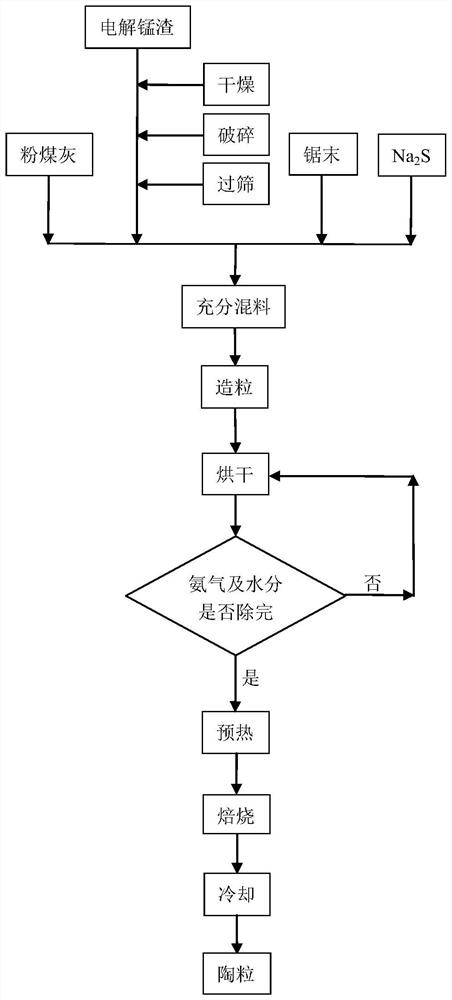

Method used

Image

Examples

Embodiment 1

[0065] This embodiment prepares thermal insulation ceramsite according to the following steps:

[0066] Step 1. After drying the electrolytic manganese slag block at 105°C for 4 hours, crush it and pass it through a 100-mesh standard sieve to obtain the raw material of electrolytic manganese slag; dry the fly ash at 105°C for 2 hours for later use; pass the sawdust through a standard sieve, and take the average Sawdust with a particle size of <1mm was dried at 105°C for 2 hours and set aside.

[0067] Step 2, according to 100 parts of electrolytic manganese slag, 100 parts of fly ash, 5 parts of sawdust, Na 2 The ratio of S 1 part, the raw material of electrolytic manganese slag, fly ash, sawdust and Na 2 S Mix well.

[0068] Step 3, granulation

[0069] Use the mechanical granulation method to granulate the mixed material obtained in step 2 (using a ZL-500 granulator), and the granulation size is 10mm-15mm to obtain pellets.

[0070] Step 4, drying

[0071] Put the pelle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com