Liquid crystal glass substrate thinning etching equipment

A liquid crystal glass substrate and etching equipment technology, which is applied in the field of liquid crystal glass substrate thinning and etching equipment, can solve the problems of unevenness, roughness, white powdery precipitation, easy deposition and adhesion of the lower end of the glass, and achieve the effect of improving the surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

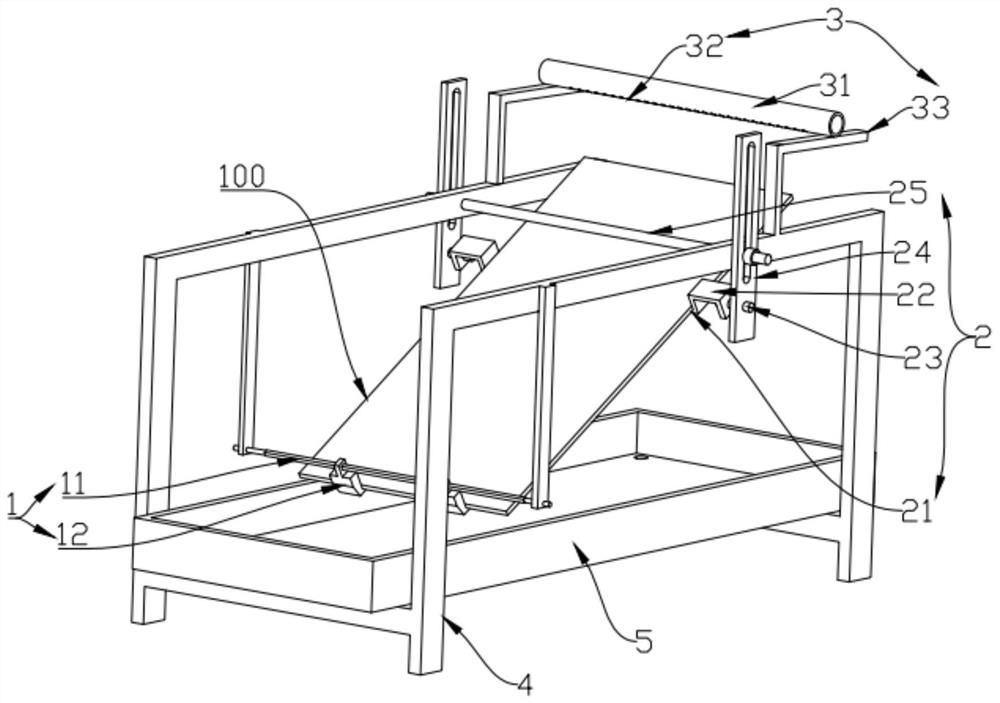

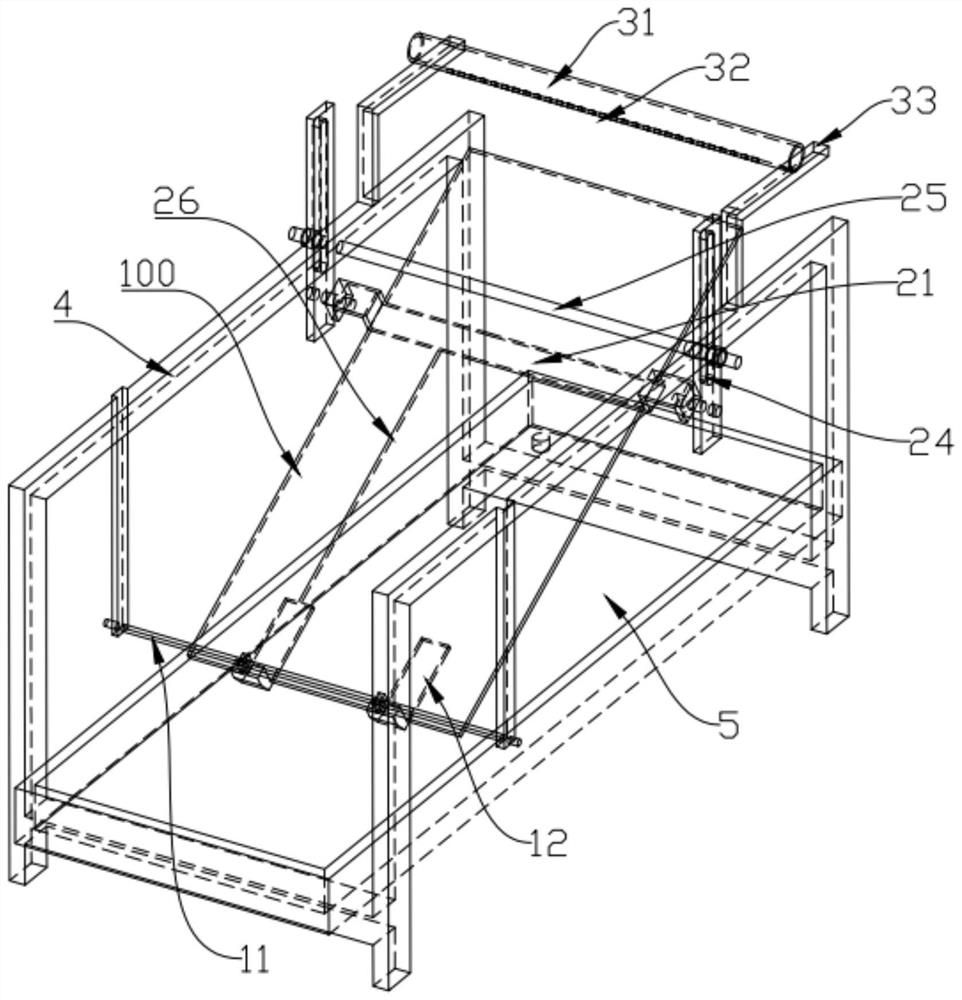

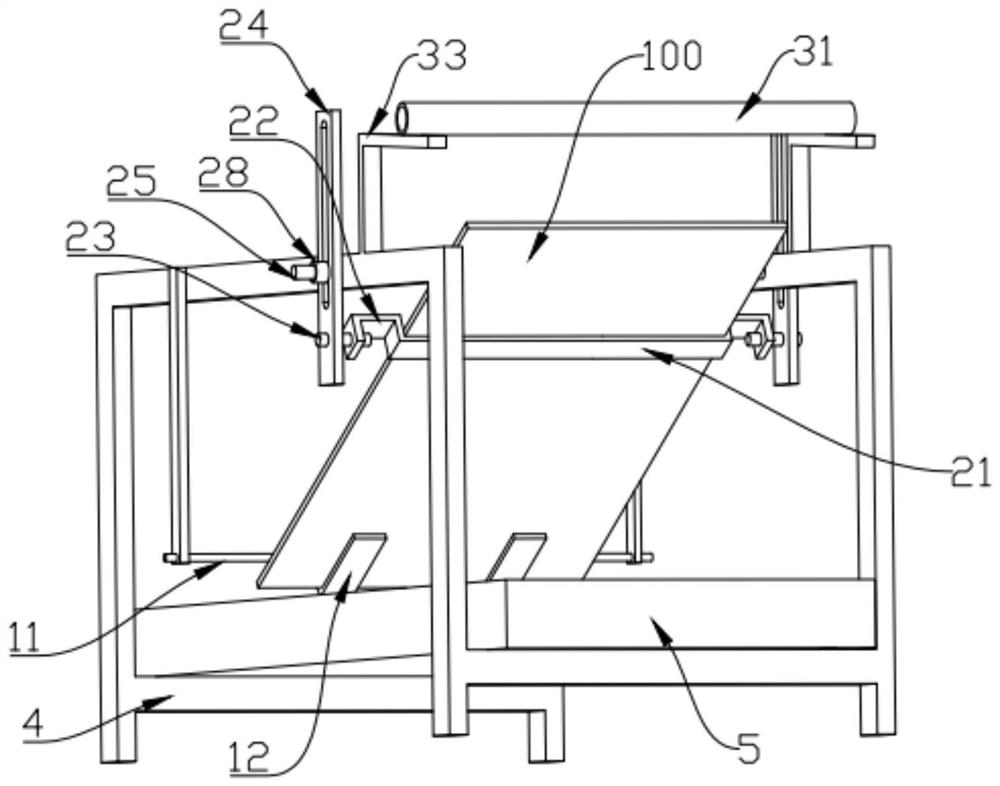

[0025] Such as figure 1 and figure 2 As shown, the technical solution of the present invention is a liquid crystal glass substrate thinning etching equipment, including a frame 4 and a liquid collection tank 5 arranged at the bottom of the frame 4, and also includes a mounting device for installing a glass substrate 100 and a spraying Etching solution spraying device 3. The installation device includes a central end 1 and a free end 2 oppositely arranged. The free end 2 rotates around the central end 1 to change the inclination angle of the glass substrate 100 placed on the installation device. The shower device 3 is arranged at the upper position of the upper end of the inclined glass substrate 100 , and uniformly sprays etching solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com