Alternating-current ice melting device and method for continuously adjusting voltage frequency of multiple branches of distribution network

A technology of voltage frequency and ice-melting method, which is applied in the field of AC ice-melting devices, can solve the problems of hard-to-distribute network multi-branch line melting, low efficiency of machine-melting ice-melting ice, and limited ice-melting range, etc., to increase the ice-melting function , Improve the efficiency of ice melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

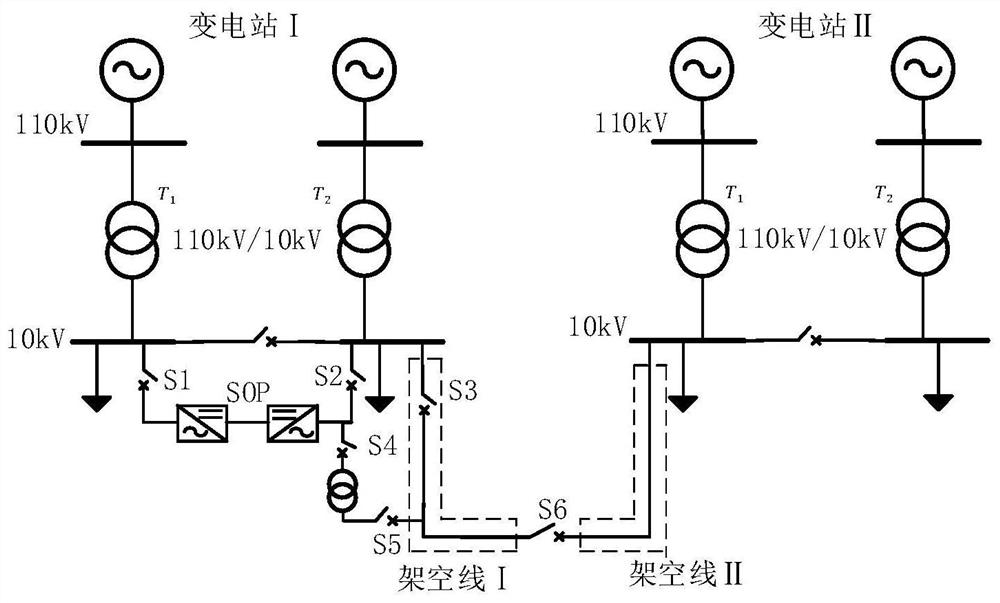

[0029] Embodiment 1 of the present invention provides a configuration structure of a variable frequency AC deicing system suitable for flexible substations and continuous regulation of voltage and frequency. The specific implementation is as follows figure 1 shown. The implementation premise of the present invention is that a B2B-MMC replacement contact switch is installed in the substation, and its common function is power flow control. The content contained in the common function is not the content of the present invention. The present invention is a new function and new technology. In terms of B2B-MMC access mode, the difference from conventional functions is that it is connected to an ice-melting transformer and ice-melting circuit breaker S4, S5, so that it can adapt to the complex status of multi-branch ice melting in the distribution network. Handle overhead lines, branch lines or overhead main lines. When the ice-melting side inverts the AC power with too high voltage...

Embodiment 2

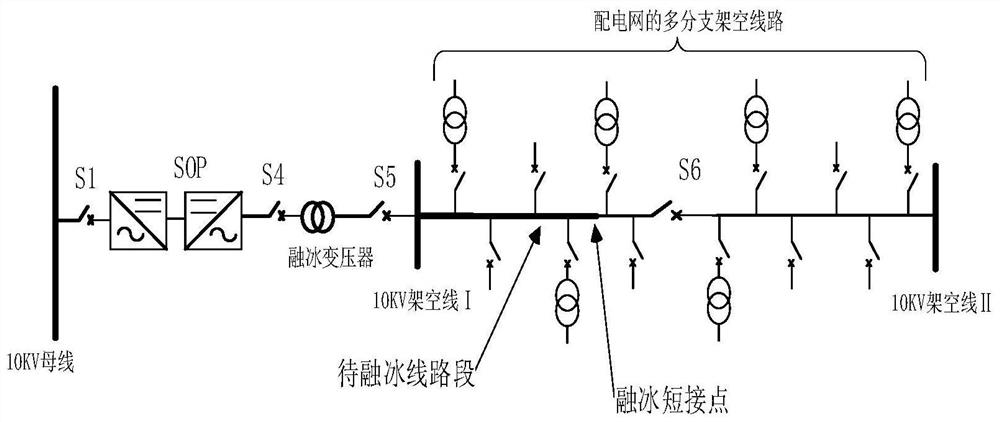

[0031] Embodiment 2 of the present invention provides a variable-frequency AC ice-melting technology model suitable for multi-branch distribution network and continuous adjustment of voltage and frequency. The specific implementation is as follows figure 2 shown. A control flow of frequency conversion AC ice-melting technology proposed by the present invention, which is suitable for multi-branch distribution network and continuous adjustment of voltage and frequency, includes the following steps:

[0032] Step 101: Determine the online ice-melting target line;

[0033] Step 102: Close the switches S4 and S5, connect to the ice-melting system and form an ice-melting circuit

[0034] Step 103: B2B-MMC switches to ice melting mode;

[0035] Step 104: Calculate the current required for ice melting;

[0036] Step 105: Adjust the frequency parameter of the inverter and the transformation ratio of the ice-melting transformer according to the ice-melting current;

[0037] Step 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com