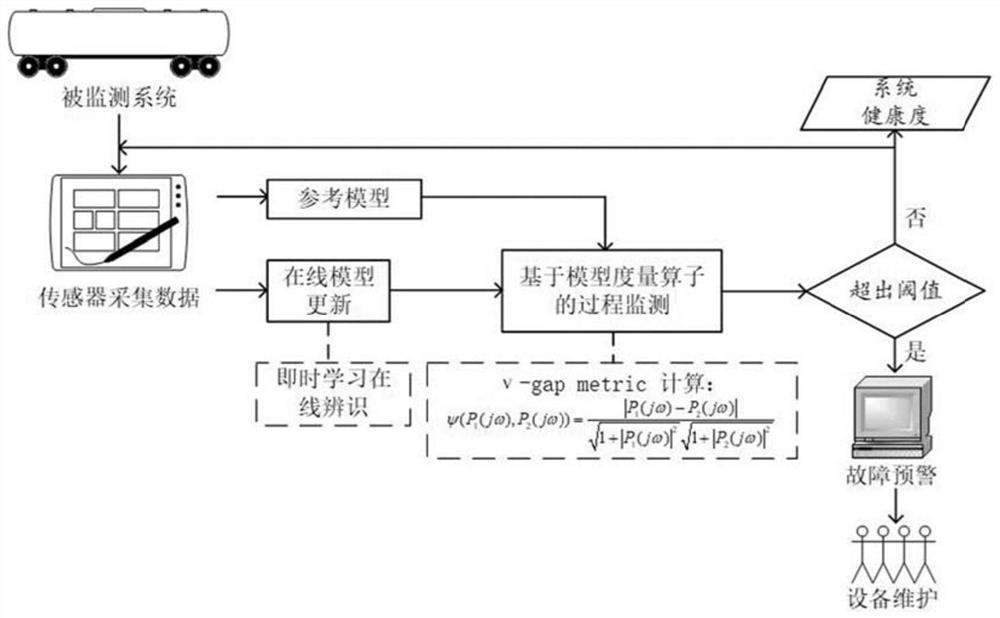

Device system health degree online monitoring method based on v-gap metric

A technology of system health and curves, applied in general control systems, control/regulation systems, test/monitoring control systems, etc., can solve problems such as poor monitoring effects in the transient state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

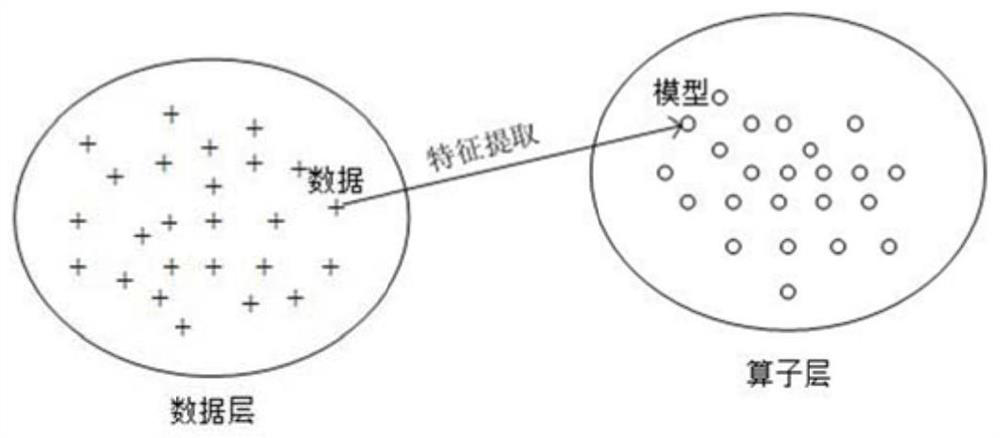

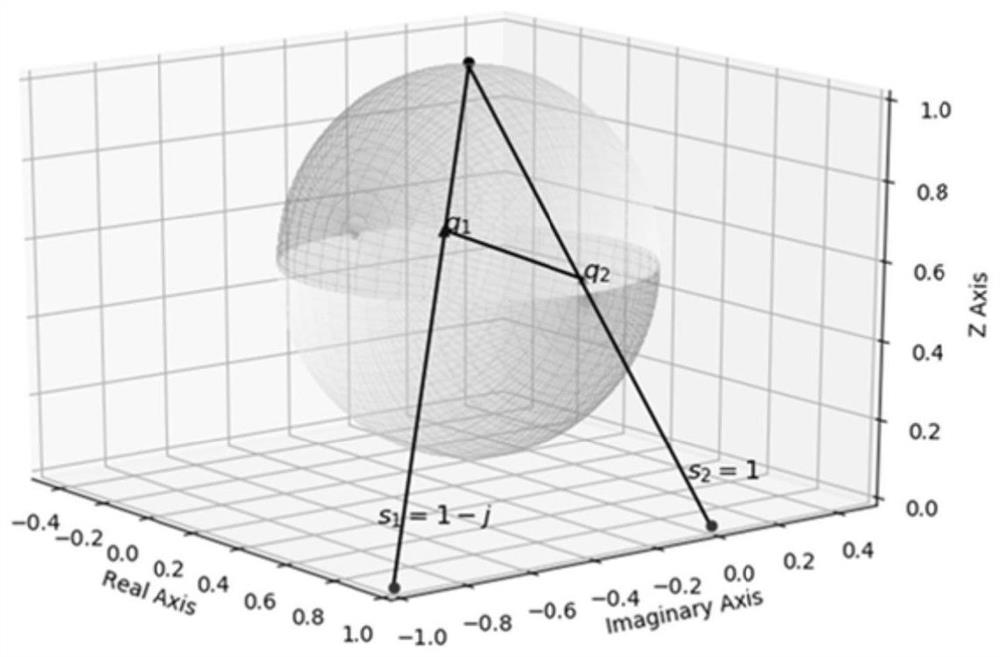

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in more detail below in conjunction with the accompanying drawings, and the advantages and implementation details of the present invention will become clearer. It should be noted that the following are only preferred embodiments of the present invention, but the present invention is not limited thereto, and the method is applicable to various industrial device systems that require health monitoring, such as the monitoring of voltage and current in a traction driving control system; The influence of reactant temperature and flow rate on dissolved oxygen concentration in the process of penicillin pharmaceutical, etc.

[0040] The present invention will be further described in detail below with a simulation example of a continuous stirred reactor system (CSTR) in conjunction with the accompanying drawings. CSTR is a tank reactor with a stirring paddle, which stirs the material to achieve a uniform state, which is beneficial to the un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com