Power system without air intake and compression stroke

A technology of power system and compression stroke, which is applied in the field of power system without intake and compression stroke, can solve the problems of large external force, achieve the effect of saving compression stroke and improving power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

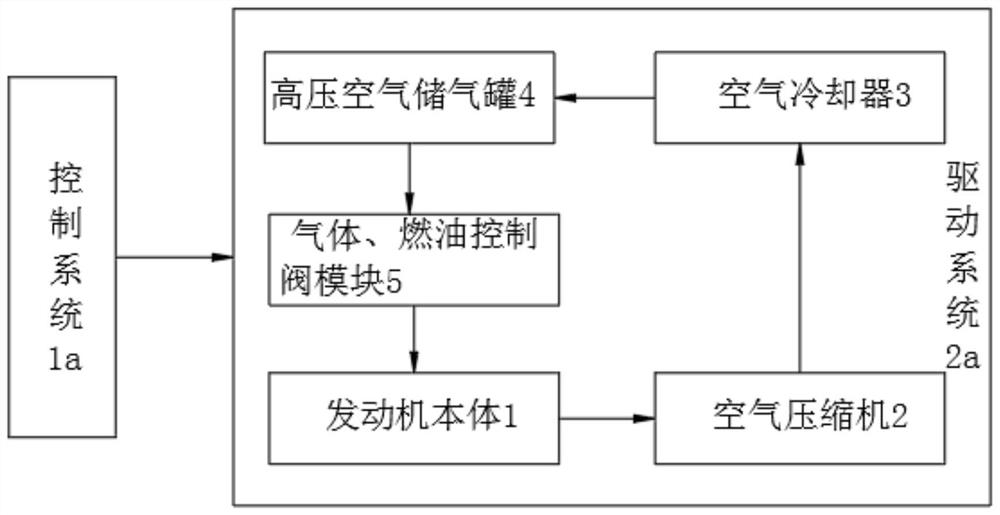

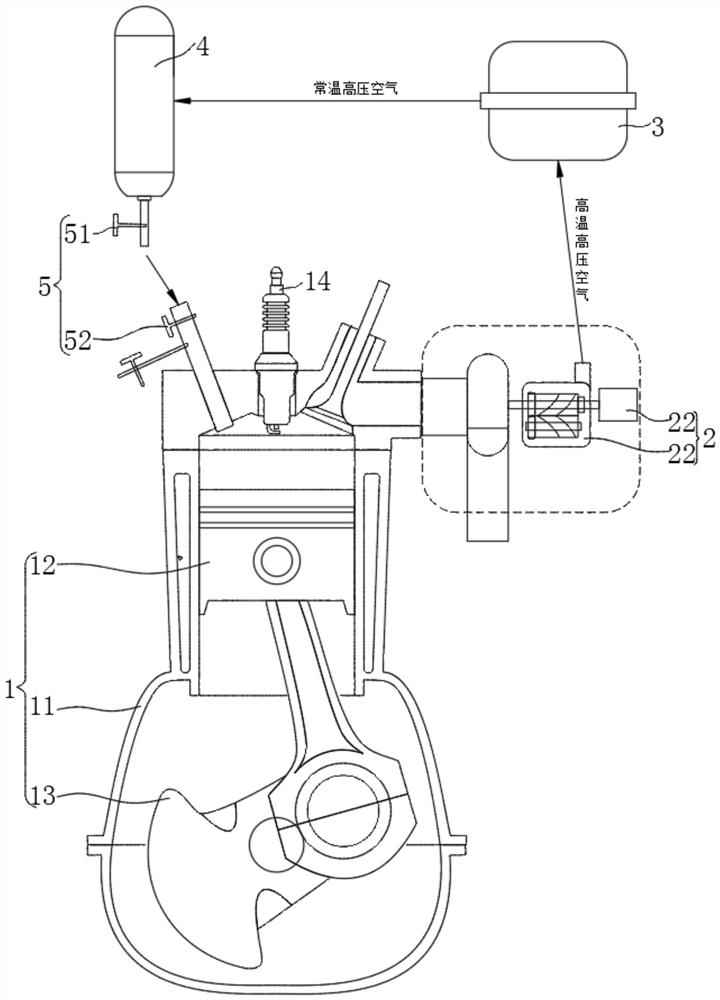

[0043] Please refer to figure 1 with figure 2 ,in, figure 1 The system block diagram of the power system without intake and compression stroke provided by the present invention; figure 2 A physical diagram of the power system without intake and compression stroke provided for the present invention. No intake and compression stroke powertrain, including:

[0044] control system 1a and drive system 2a;

[0045] Wherein, the drive system 2a includes an engine body 1, an air compressor 2, an air cooler 3, a high-pressure air storage tank 4, and a gas-fuel control valve module 5, and the output end of the air compressor 2 is connected to the air The input end of the cooler 3 is connected through a pipeline, the output end of the air cooler 3 is connected with the input end of the high-pressure air storage tank 4 through a pipeline, and the output end of the high-pressure air storage tank 4 is connected with the engine body 1 The air inlet of the gas-fuel control valve module...

no. 2 example

[0059] Based on the first embodiment of the present invention, a power system without intake and compression stroke, the second embodiment of the present invention provides another power system without intake and compression stroke, wherein, the second embodiment does not interfere with the first An independent implementation of the technical solution of an embodiment.

[0060] Specifically, the present invention provides another power system without intake and compression strokes. The difference lies in:

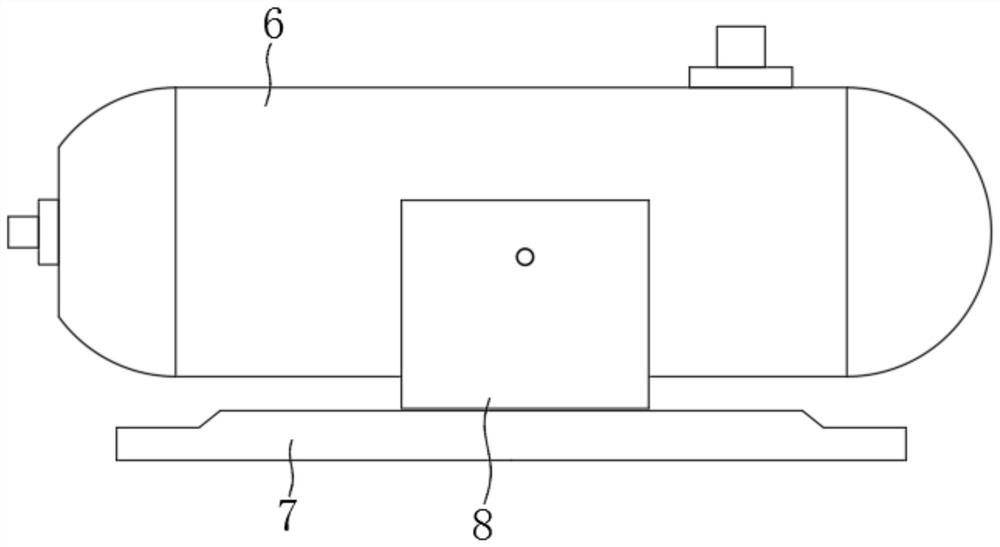

[0061] The high-pressure air storage tank 4 includes a tank body 6 and an installation base plate 7, the top of the installation base plate 7 is provided with a connection seat 8, and both sides of the connection seat 8 are provided with a fixed structure 9, and the fixed structure 9 It includes a connecting block 91, a fixing clip 92, a push piece 93 and an elastic piece 94. The bottom of the connecting block 91 is provided with a fixing groove 95, and the fixing clip 92 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com