Large-diameter vertical well exploring machine

A large-diameter, well-exploring rig technology, applied to drilling equipment, directional drilling, earthwork drilling and production, etc., can solve problems such as low work efficiency, increased working time, and deviation of hole verticality, so as to improve the effect and efficiency, and improve work Efficiency, the effect of ensuring verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

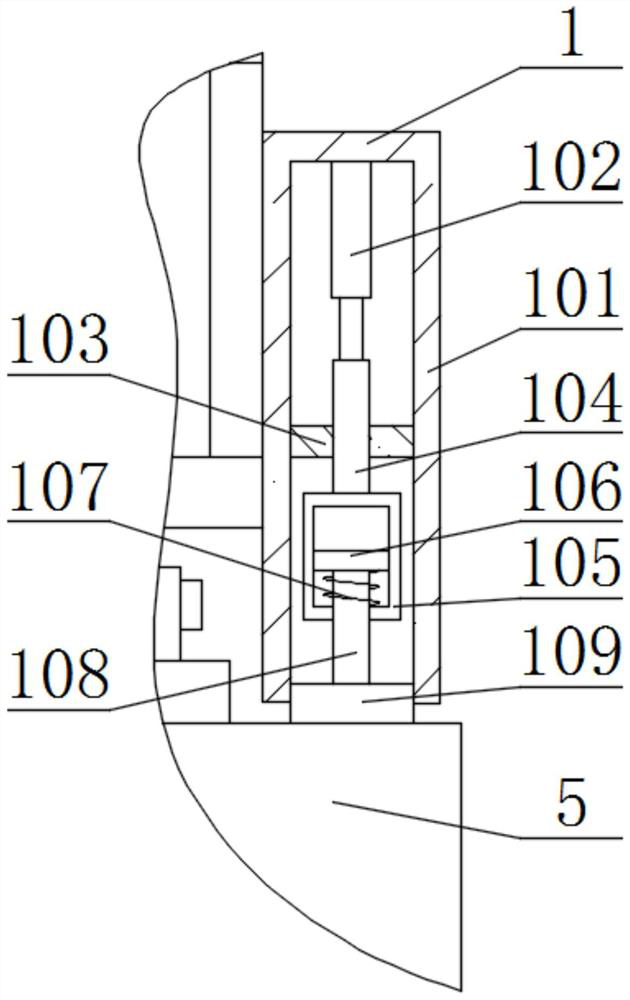

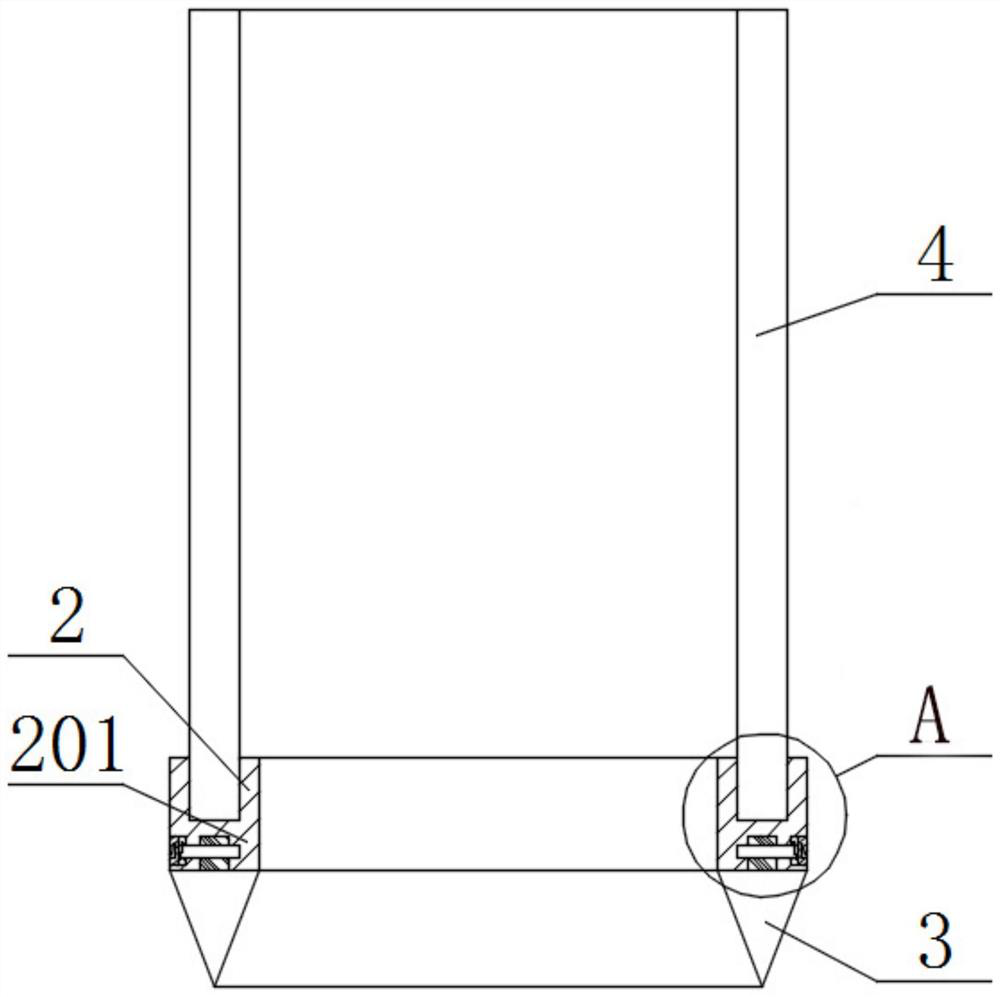

[0026] see Figure 1-5 , the present invention provides a technical solution:

[0027] The large-diameter vertical drilling machine includes a drilling machine main body 5, one end of the drilling machine main body 5 is fixedly connected with an auxiliary drop device 1, and the bottom end of the drilling machine main body 5 is provided with a soil cutting part 4, and the soil cutting part The bottom end of 4 is fixedly connected with a connecting device 2, and the bottom end of the connecting device 2 is fixedly connected with a cutter 3, and a probe mechanism 6 is arranged on the lower part of the main body of the drilling machine 5 and inside the soil cutting part. The needle mechanism 6 is used to ensure the verticality of the holes dug under the soil-cutting part 4. The length of the probe mechanism 6 is greater than the length of the soil-cutting part 4, so that when the large-diameter vertical well-exploring machine falls, the probe mechanism can 6 Guarantee the vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com