Circular knitting machine for knitting fabric spinning

A technology of knitted fabrics and circular knitting machines, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of easy wrinkling of knitted fabrics, uneven tightness, and poor winding effect of winding mechanism, so as to ensure stability High stability and load capacity, guaranteed stability and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of circular knitting machine for weaving knitted fabrics, such as Figure 1-10 As shown, it includes: a frame 1 for supporting and fixing the tension control component 2, the tension control component 3, the winding component 4, the smoothing component 5, the moving component 8 and the linkage component 9;

[0037] The tension component is located above the frame 1, the tension component is set above the frame 1 through the support of the tension control component 3, and the tension control component 3 is clamped on the surface of the frame 1;

[0038] The winding assembly 4 is arranged on the side of the tension control assembly 2, and the bottom of the winding assembly 4 is fixedly connected to the top of the frame 1, wherein the smoothing assembly 5 is arranged on the side of the winding assembly 4 away from the tension control assembly 2.

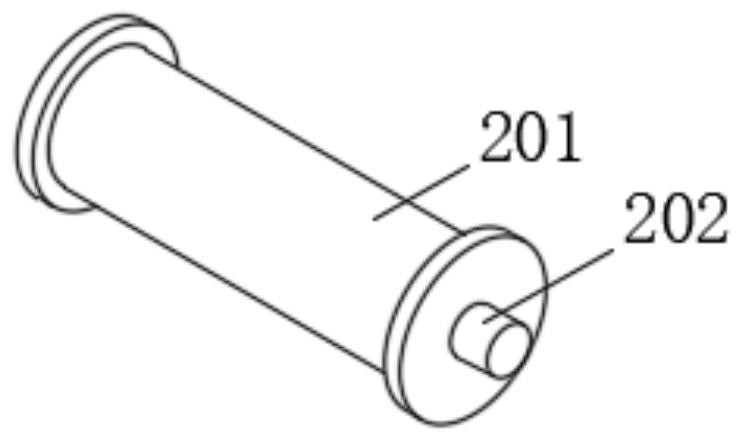

[0039] The tension control assembly 2 includes a receiving roller 201, which is located above the frame 1. The end surfa...

Embodiment 2

[0045] A kind of circular knitting machine for knitting fabric weaving, differs from embodiment 1 in that, as figure 1 As shown, the top of the frame 1 is provided with a winding assembly 4;

[0046] The winding assembly 4 includes a winding roller 401, the winding roller 401 is located above the frame 1, the end surface of the winding roller 401 is fixedly connected with a fourth transfer shaft 402, and the surface of the fourth transfer shaft 402 is sleeved with a first Four bearings 403 , the fourth bearing 403 is clamped on the side close to the first side seat 404 , and the bottom of the fourth bearing 403 is fixedly connected with the top of the frame 1 .

[0047] In practical applications, a drive device needs to be installed at the end of one of the fourth adapter shafts 402 before operation, and the operation of the drive device should be controlled. The output shaft of the drive device will drive the fourth adapter shaft 402 during operation. Rotation occurs in the ...

Embodiment 3

[0049] A kind of circular knitting machine for knitting fabric weaving, differs from embodiment 1 in that, as figure 1 As shown, the top of the base is provided with smoothing components 5;

[0050] The smoothing device includes a smoothing roller 501, a fifth transfer shaft 502 is fixedly connected to the end surface of the smoothing roller 501, and a fifth bearing 503 is sleeved on the surface of the fifth transfer shaft 502, and the fifth bearing 503 is clamped on the second On one side close to the two side side seats 504, the bottom of the second side side seat 504 is fixedly connected with a sliding connecting seat 6, and the second sliding connecting seat 6 is slidably connected in the sliding connecting groove 7 provided at the top of the base.

[0051] The moving assembly 8 includes a driving wheel 801, the driving wheel 801 is fixedly connected to the surface of the fourth transfer shaft 402, the driving wheel 801 is connected to the driven wheel 803 through a belt 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com