Handle forming mold

A technology for forming a mold and a handle, applied in the field of mold manufacturing, can solve the problems of complicated operation steps and complex mold structure, and achieve the effects of simplifying the mold structure, good responsiveness, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

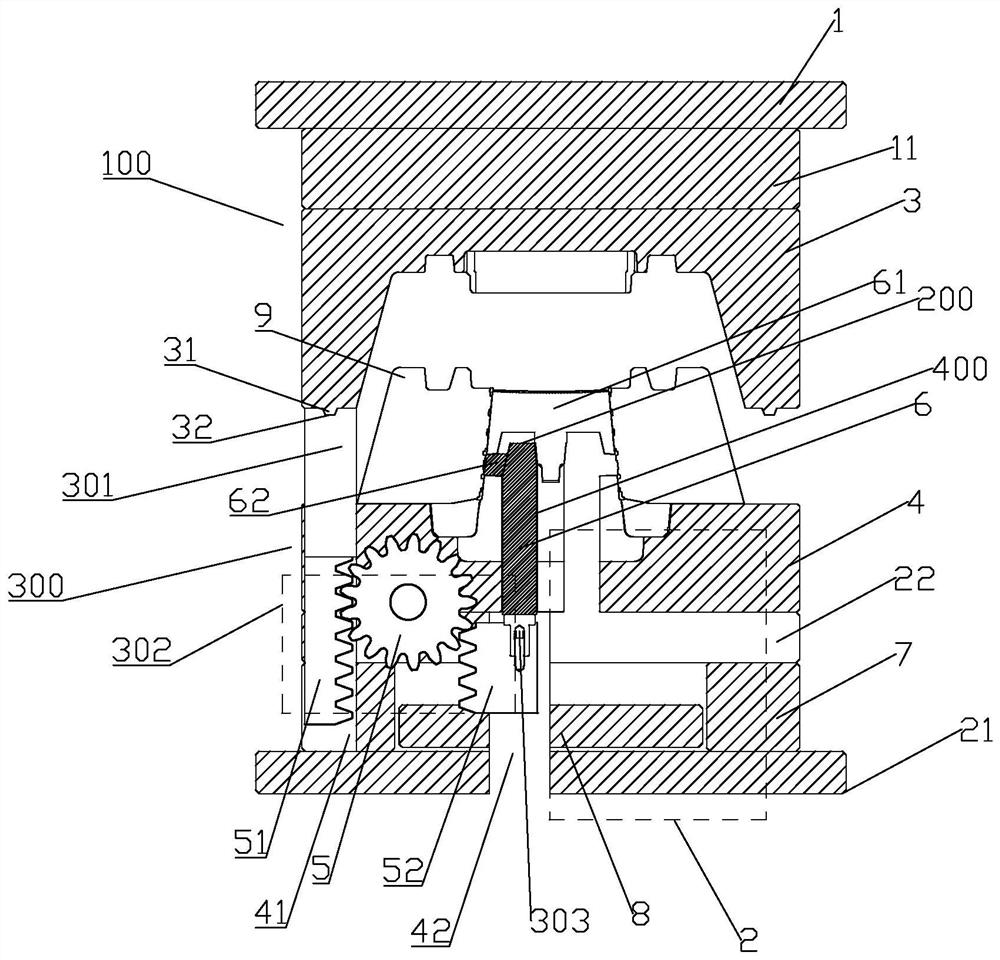

[0025] Such as figure 1 As shown, a handle forming mold includes: a mold body 100, the mold body 100 includes an upper doubler plate 1 and a lower doubler plate assembly 2, a cavity 3 is provided under the upper doubler plate 1, and the lower doubler plate assembly 2 A core 4 is provided above, and a handle internal molding device 200 is provided between the core 4 and the lower doubler plate assembly 2, the handle internal molding device 200 includes a transmission mechanism 300 and a molding assembly 400 connected to the transmission mechanism 300, The transmission mechanism 300 can drive the molding assembly 400 to perform internal molding of the handle product through the mold clamping force, and the transmission mechanism 300 can drive the molding assembly 400 to release the handle product through the mold opening force. In the traditional injection molding process, after the overall cooling of the mold, the molded product is ejected from the core 4 to complete demoulding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com