Square edge sealing production line system and square edge sealing production method thereof

A production line and square technology, used in forming/shaping machines, manufacturing tools, wood processing appliances, etc., can solve the corner size, the perpendicularity error of each adjacent side, the lack of fixed length, fixed width processing, lack of alignment problems such as datum edges, to achieve the effect of reducing springboard and offset, novel structure, and improving work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention. The present invention will be described in detail below in conjunction with the accompanying drawings.

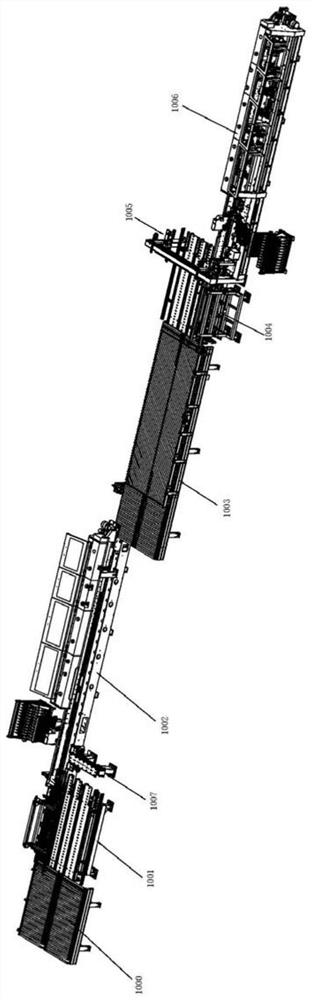

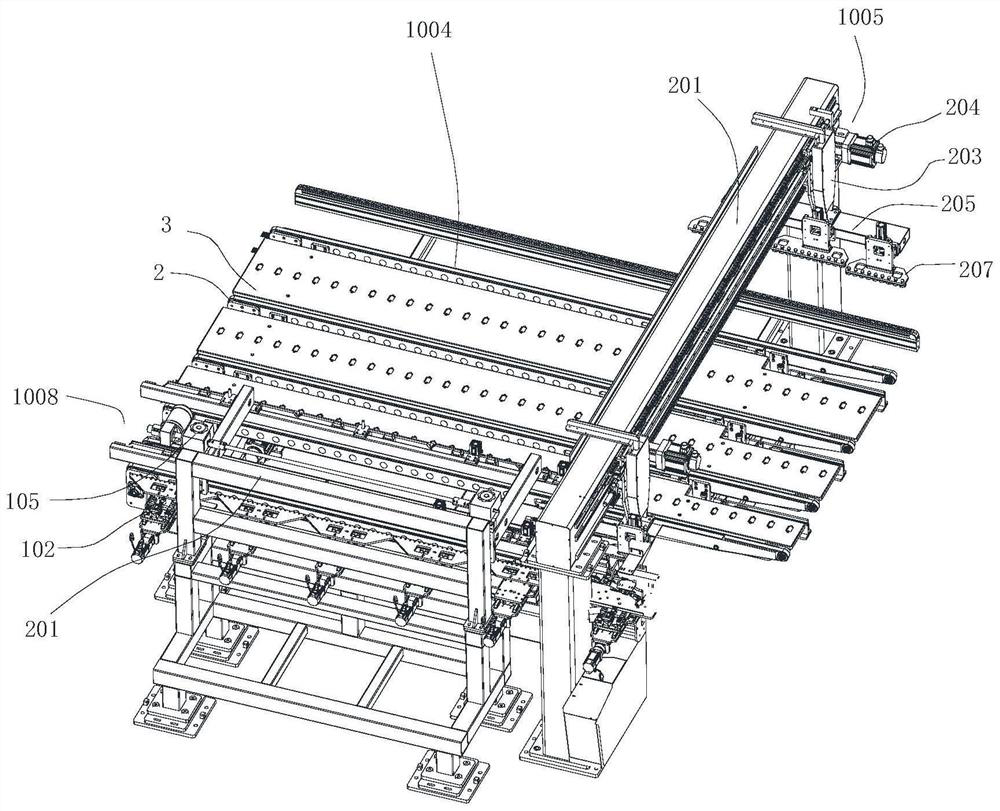

[0074] A standard side banding production line system, such as Figure 1 to Figure 23 As shown, there are feeding conveyor 1001, left correction conveyor 1002, left intelligent edge banding machine 1003, double-row oblique roller conveyor 1004, right correction conveyor 1005, and gantry side positioning mechanism in sequence along the plate conveying direction. 1006 and the right-hand intelligent edge banding machine 1007;

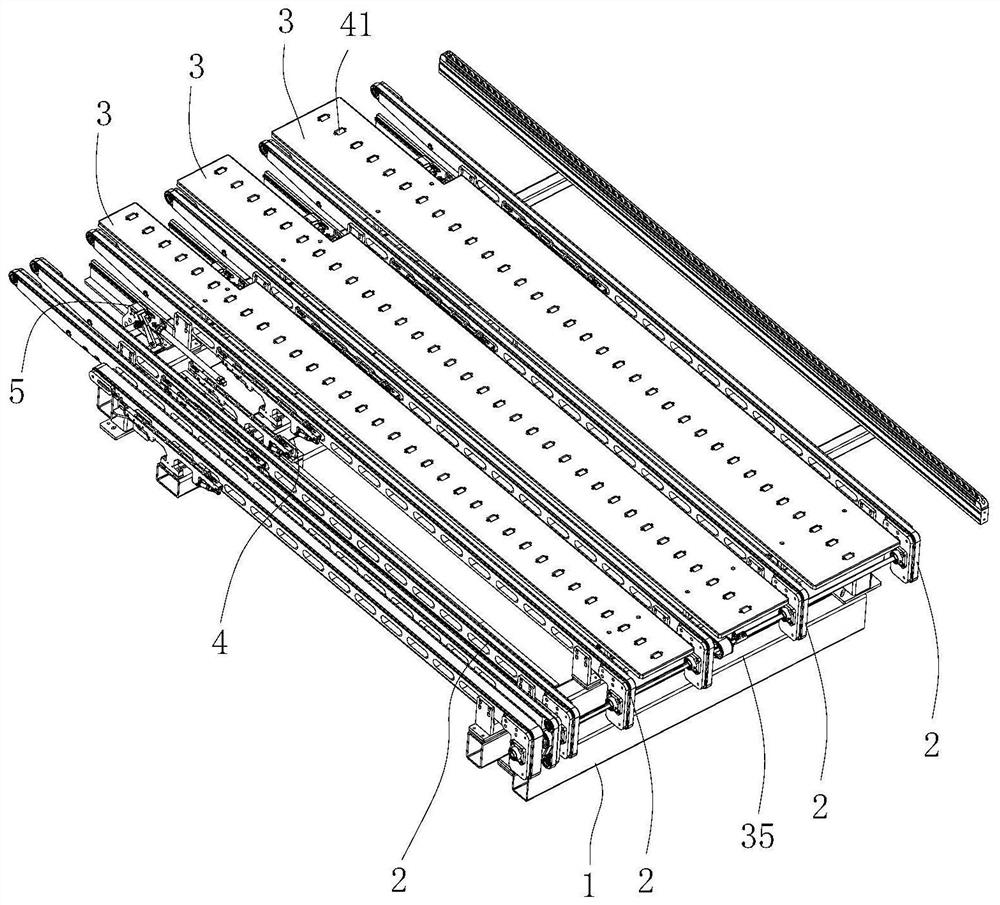

[0075] Both the leftward correction conveying platform and the rightward correcting conveying platform comprise an underframe 1, a plurality of belt transmission units...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com