Double-lead-screw-driven automatic turnover numerical control rotary table

A rotary table and automatic flip technology, applied in the direction of worktables, manufacturing tools, etc., can solve the problems that it is difficult to balance processing efficiency and precision at the same time, and cannot meet the needs of intelligent processing, so as to improve processing efficiency and processing accuracy, and stabilize the structure , good synchronization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

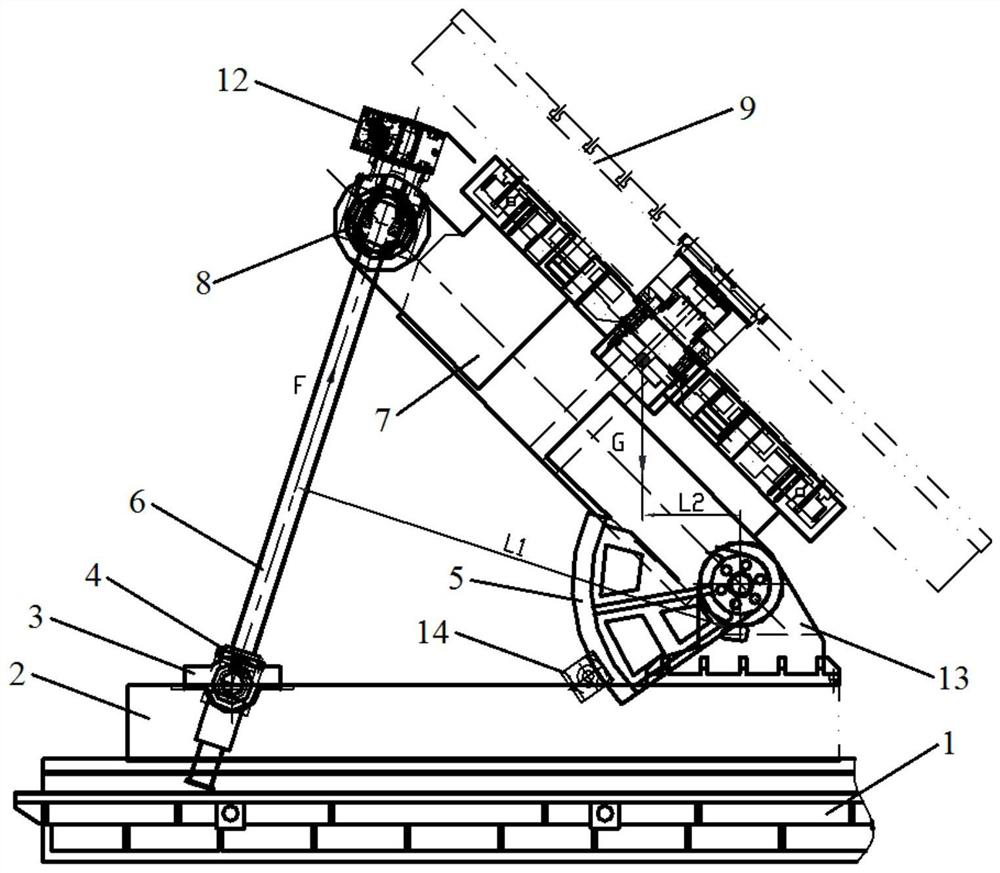

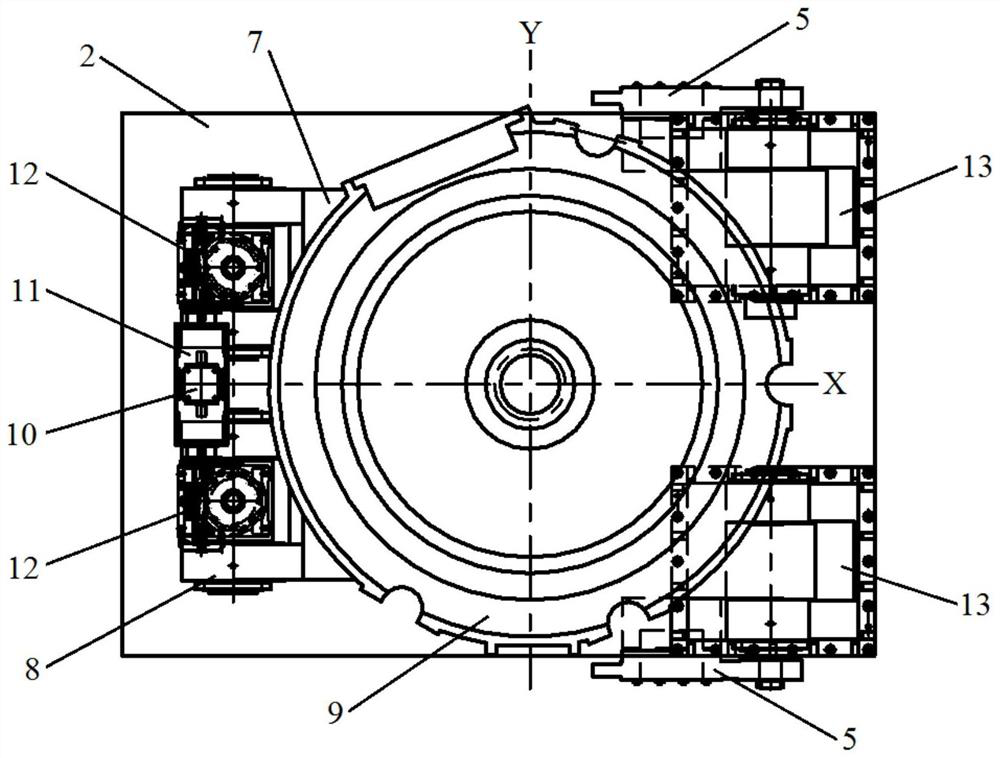

[0016] Regarding the aforementioned and other technical contents, features and effects of the present invention, refer to the appended figure 1 to attach figure 2 It will be apparent from the detailed description of the embodiments. The structural contents mentioned in the following embodiments are all based on the accompanying drawings of the description.

[0017] Exemplary embodiments of the present invention will be described below with reference to the accompanying drawings.

[0018] The dual-screw-driven automatic flip CNC rotary table provided by the present invention mainly solves the problem that the CNC rotary table top realizes automatic flip motion at any angle within the range of 0 to 45°, and can realize precise control of positioning accuracy and repeat positioning accuracy during the flipping process. . The solution is to adopt the servo motor-driven double-screw flip technology on the table of the rotary table, that is, to use a servo motor to connect the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com