Hot-metal bottle heat preservation covering agent spreading device

A technology of thermal insulation covering agent and spreading device, which is applied to casting melt containers, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing the thermal insulation effect of the covering agent, poor working efficiency of the device, not covering the covering agent, etc. Quality and thermal insulation effect, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

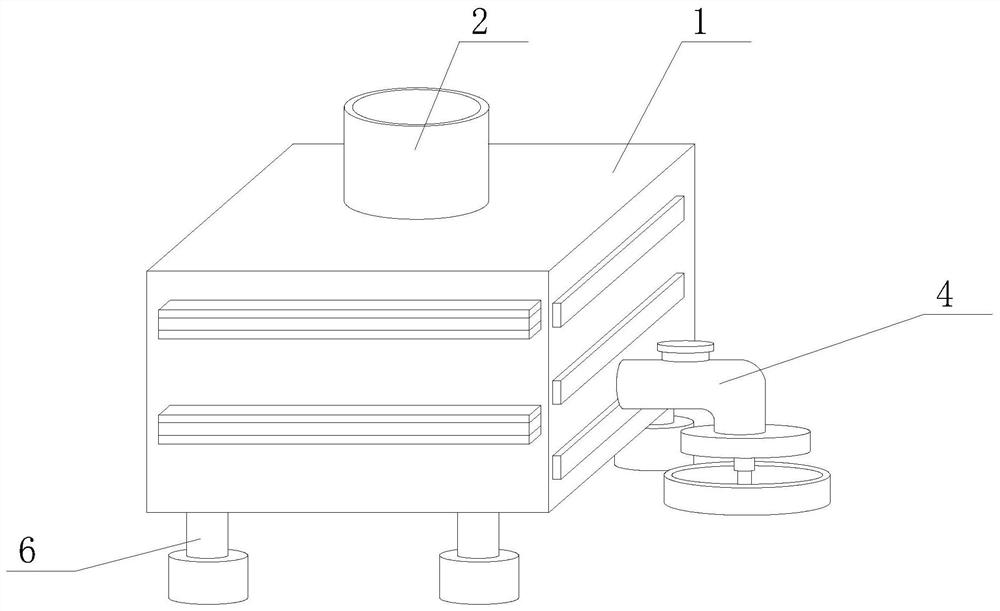

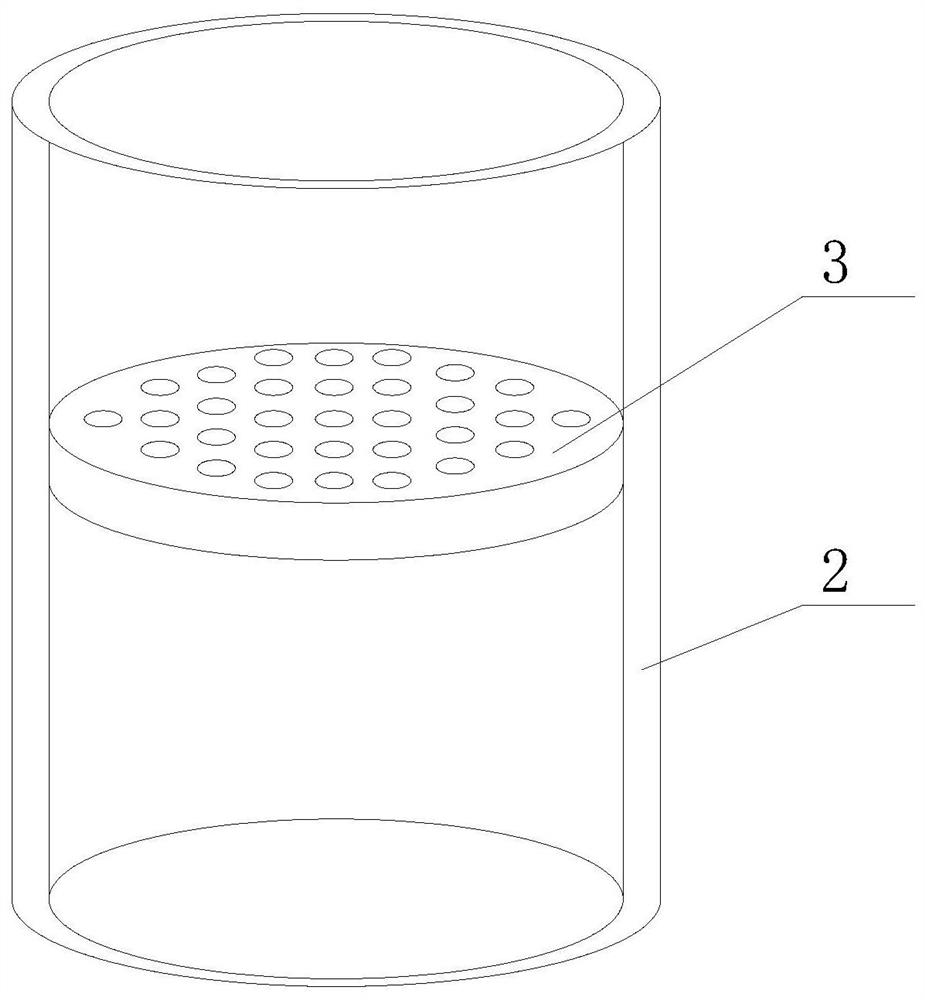

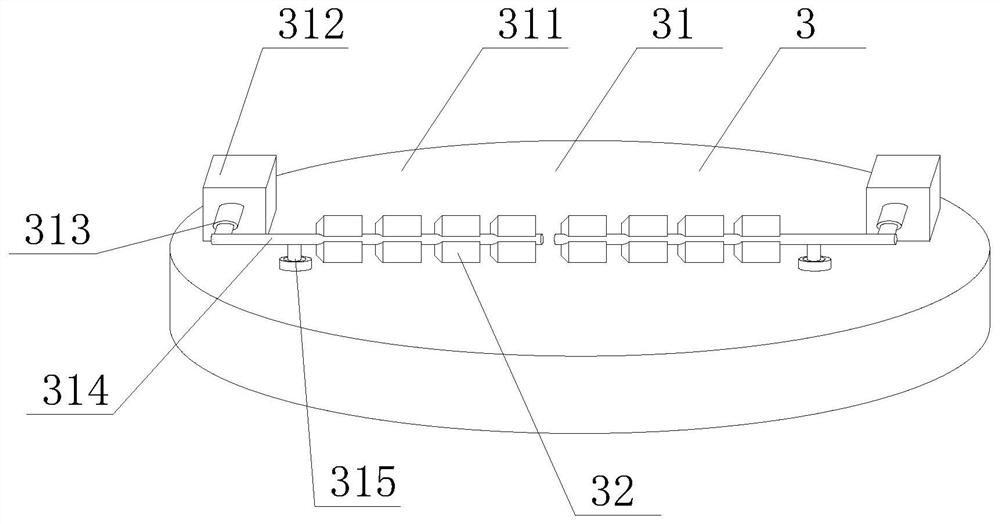

[0049] Such as Figure 1-9As shown, the present invention provides a spreading device for heat preservation and covering agent for molten iron tanks, comprising a spreading device body 1, a feeding pipe 2 and a support column 6, the top of the spreading device body 1 is fixedly connected with a feeding pipe 2, and the spreading device body 1 The four corners of the bottom are fixedly connected with support columns 6, the inner cavity of the feed pipe 2 is fixedly sleeved with a removal device 3, the bottom of one side of the spreading device body 1 is fixedly connected with a spraying device 4, and the removal device 3 includes a driving device 31 And the vibrating device 32, the driving device 31 includes a sieve plate 311, the outer wall of the sieve plate 311 is fixedly sleeved in the inner cavity of the feed pipe 2, the two sides of the top of the sieve plate 311 are fixedly connected with fixed blocks 312, and the sieve plate 311 is provided with There are through holes, ...

Embodiment 2

[0052] Such as Figure 1-9 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the spraying device 4 includes a charging tank 44, and the inner cavity of the charging tank 44 is fixedly connected with a support plate 46, and the support plate 46 The number is four, and one side of four support plates 46 is fixedly connected with a support rod 45, and the top of the support rod 45 is fixedly connected with a No. 1 motor 43, and the bottom of one side of the spreading device body 1 is fixedly connected with a conduit 41. The top is fixedly connected with a suction pump 47, the bottom of the conduit 41 is fixedly connected with a spray head 42, and the bottom of the spray head 42 is fixedly connected with the top of the No. 1 motor 43, and a leak hole is provided on the charging tank 44, which is even are distributed on the outer wall and bottom of the charging tank 44.

[0053] In this embodiment, start the suction pump 47, s...

Embodiment 3

[0055] Such as Figure 1-9 As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, the inner cavity of the spreading device body 1 is provided with a stirring device 5, and the stirring device 5 includes a No. 2 motor 51, and a No. 2 motor 51 The output end extends to the inner cavity of the spreading device body 1 and is fixedly connected with a turntable 52, the outer wall of the turntable 52 is fixedly connected with an arc-shaped stirring rod 53, and one side of the arc-shaped stirring rod 53 is fixedly connected with a fixed box 531, and the fixed box 531 One side is movably socketed with a straight rod 532, the outer wall of the straight rod 532 is fixedly connected with a blade 533, one side of the inner cavity of the fixed box 531 is fixedly connected with a micromotor 534, and the output end of the micromotor 534 is fixedly connected with one end of the straight rod 532 .

[0056] In this embodiment, the No. 2 motor 51 ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com