Diameter detection method and device suitable for cast pipe production line

A detection device and detection method technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of large diameter cast pipe curvature changes, poor detection accuracy, high cost, etc., to achieve large cast pipe range, structure Simple, easy-to-maintain effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

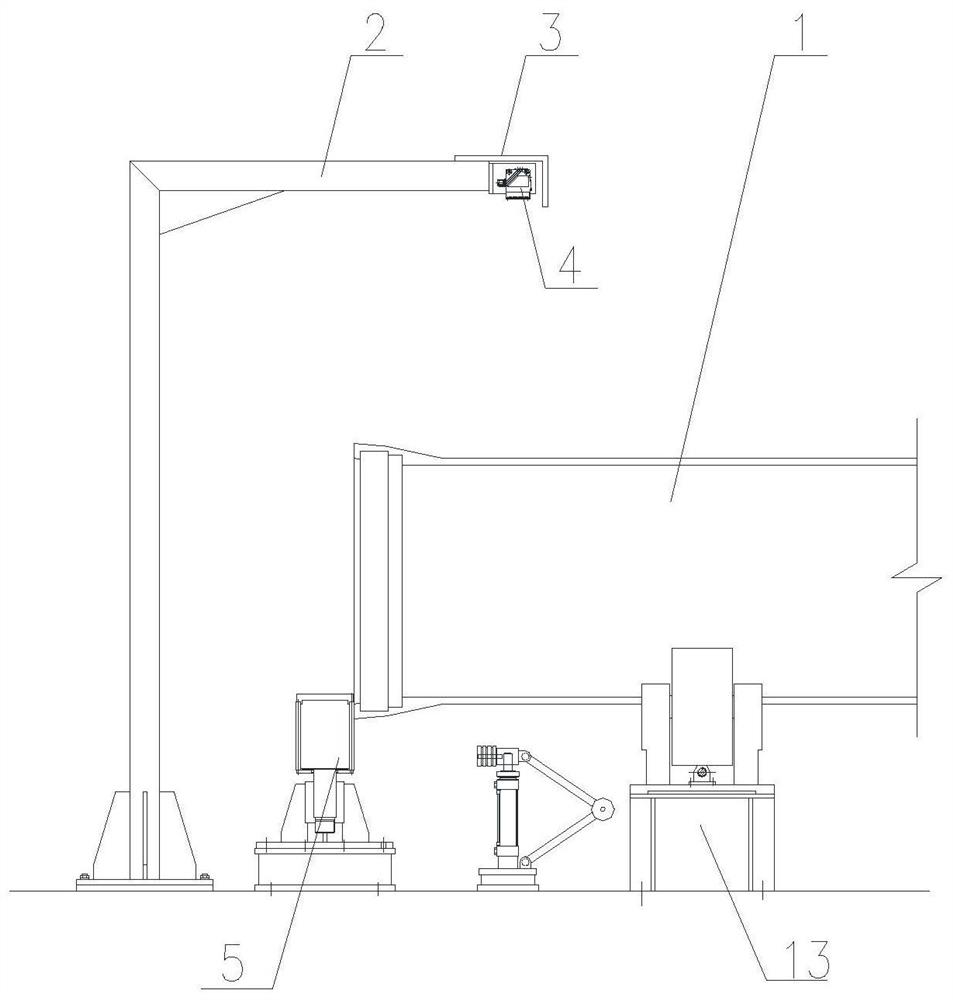

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

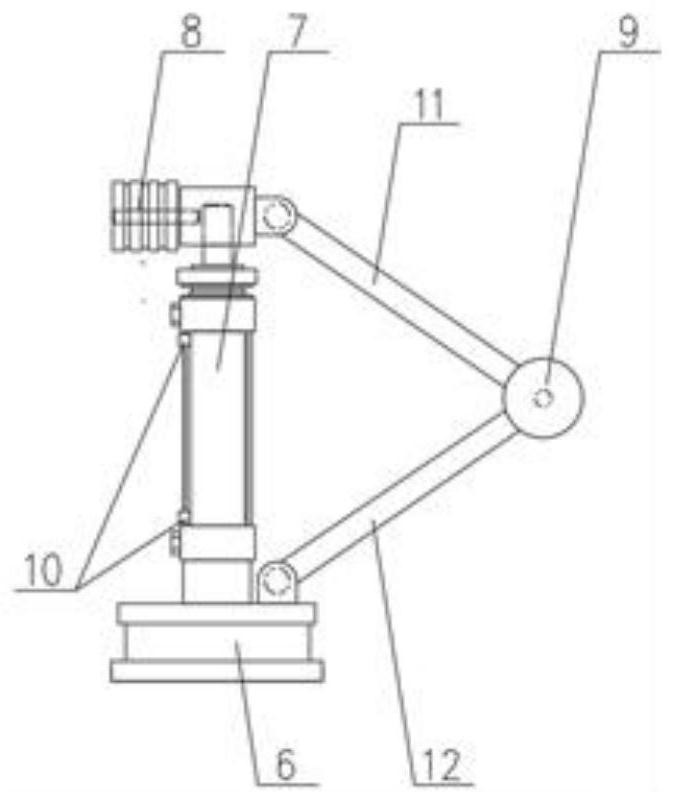

[0022] Such as figure 1 , 4 Shown, a kind of diameter detecting method that is suitable for cast pipe production line, comprises the following steps: A, measure the height L of the lower plane of laser sensor 4 to the ground 1 , L 1 Stored in the PLC controller as known data;

[0023] B. Measure the height L of the magnetic cylinder 7 contacting the roller 8 to the ground of the lower section detection device of the cast pipe when it is not extended 2 , L 2 Stored in the PLC controller as known data;

[0024] C. Calculate L 3 = L 1 -L 2 , stored in the PLC controller;

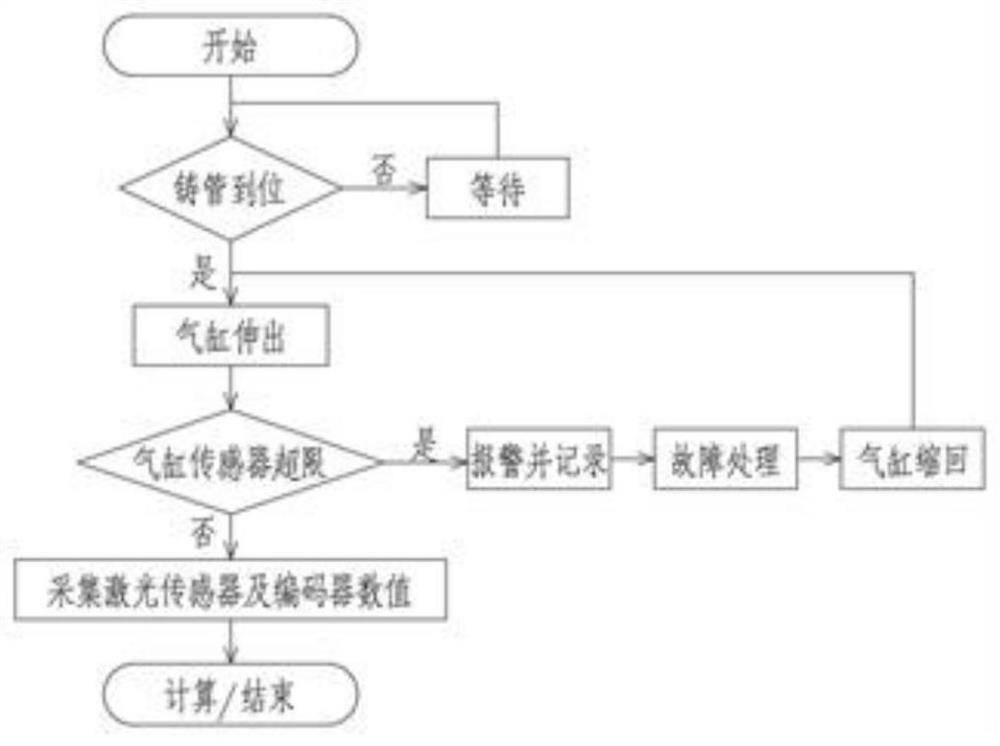

[0025] D. When the casting pipe 1 is sent from the previous station to the supporting rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com