Multilayer composite material water lubricated bearing with gradually-expanded end face

A multi-layer composite material, water-lubricated bearing technology, applied in the field of bearings, can solve the problems of insufficient load sharing and vibration damping capacity, large friction, etc., to improve load sharing and vibration damping performance, improve friction performance, and avoid end friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

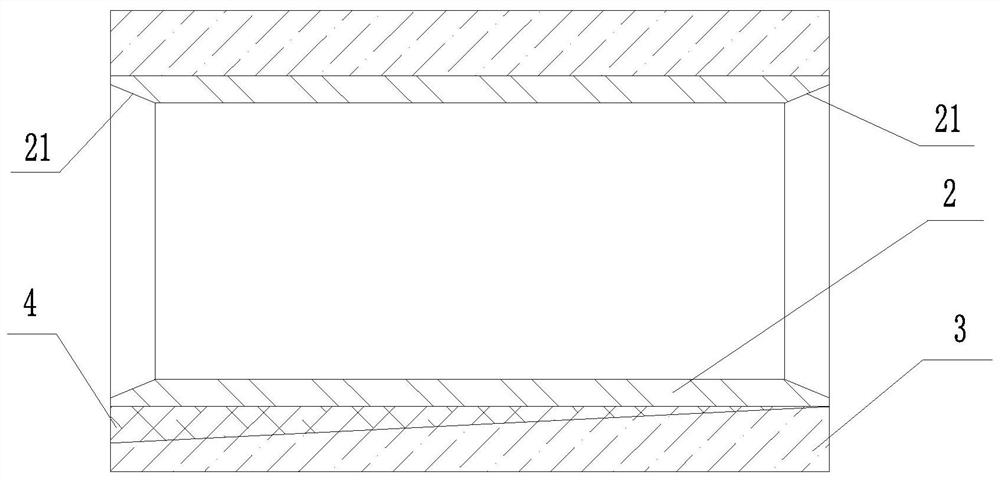

[0031] Such as figure 1 figure 2 As shown, a water-lubricated bearing with a multi-layer composite material with gradually expanding end faces, including a metal matrix 3 and a polymer lining 2, and the polymer lining 2 is arranged in the metal matrix 3;

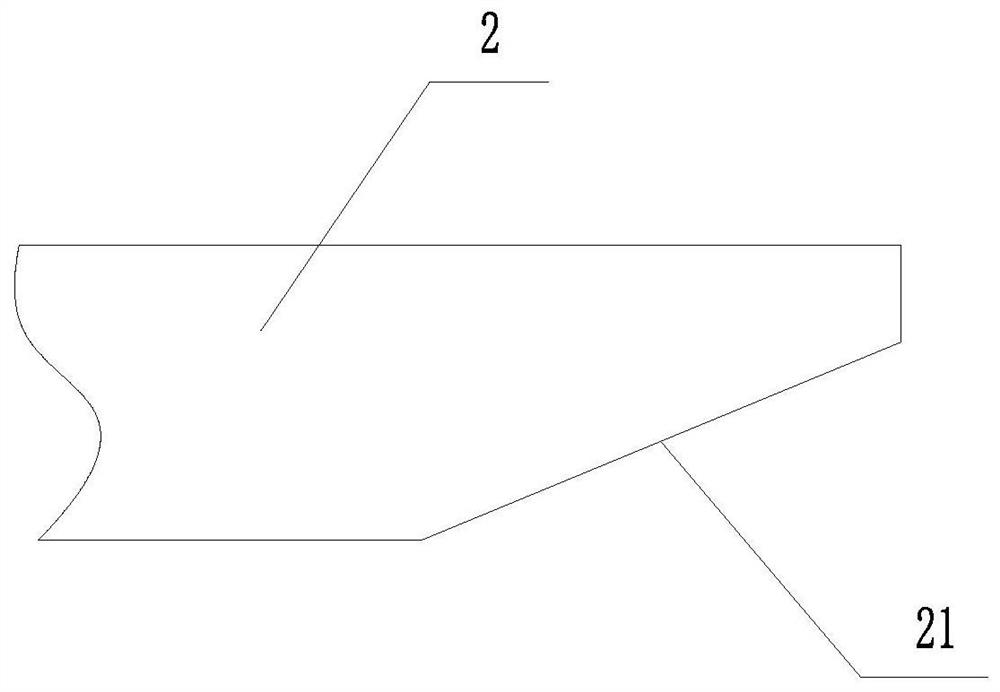

[0032] Both the left end face and the right end face of the polymer liner 2 are provided with gradually expanding holes 21; the gradually expanding holes 21 can also be provided on one side;

[0033] A supporting cavity is opened in the metal base 3, and the supporting cavity is a semi-circular structure;

[0034] A rubber support 4 is arranged in the support cavity to support the polymer liner 2 .

[0035] In this embodiment, the support member 4 is a non-uniform thickness member, and the inner wall surface of the gradually expanding hole 21 is a single slope, multiple slopes or a curved surface. Such as image 3 , Figure 4 , Figure 5 shown.

[0036] In this embodiment, the supporting member 4 is a triangular stru...

Embodiment 2

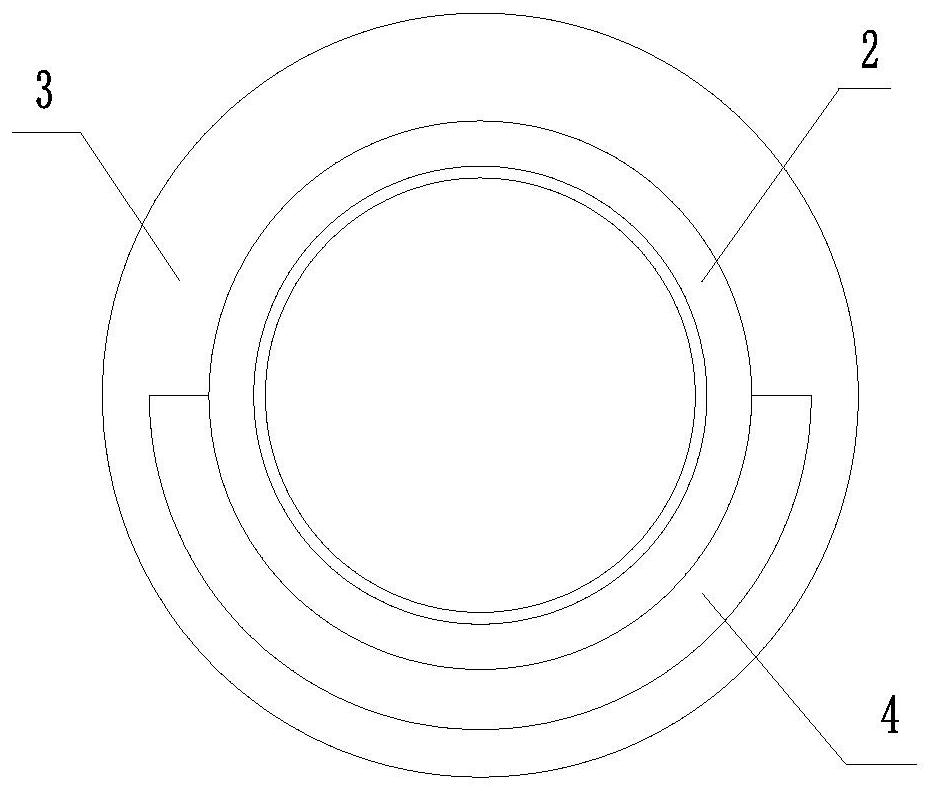

[0038] Such as Image 6 Figure 7 As shown, this embodiment is based on the first embodiment, the difference is that: the support cavity is a ring structure; the third embodiment

[0039] Such as Figure 8 As shown, this embodiment is based on the first embodiment, the difference is that: the supporting member 4 is a member of equal thickness, and the supporting cavity can be a circular or semi-circular structure.

Embodiment 4

[0041] Such as Figure 9 As shown, this embodiment is based on the first embodiment, and the difference is that the supporting cavity is a ring structure. The supporting member 4 is a trapezoidal structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com