Submarine vacuum pipeline test line capable of extending into application line and implementation method thereof

A technology of vacuum pipelines and test lines, which is applied in the test of infrastructure, water conservancy projects, artificial islands, etc., can solve the problems of long line mileage, high cost, idle or abandoned, etc., to speed up the construction process, improve the operation speed, The effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific content of the present invention will be further explained in detail below in conjunction with the examples.

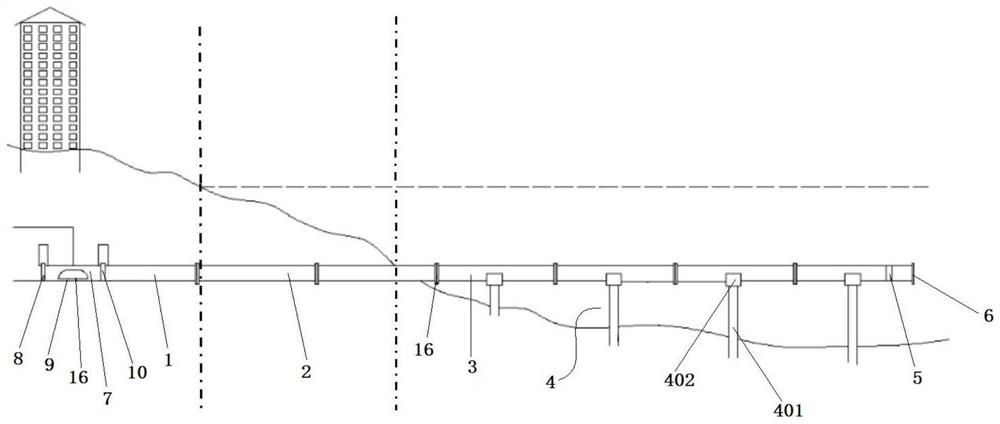

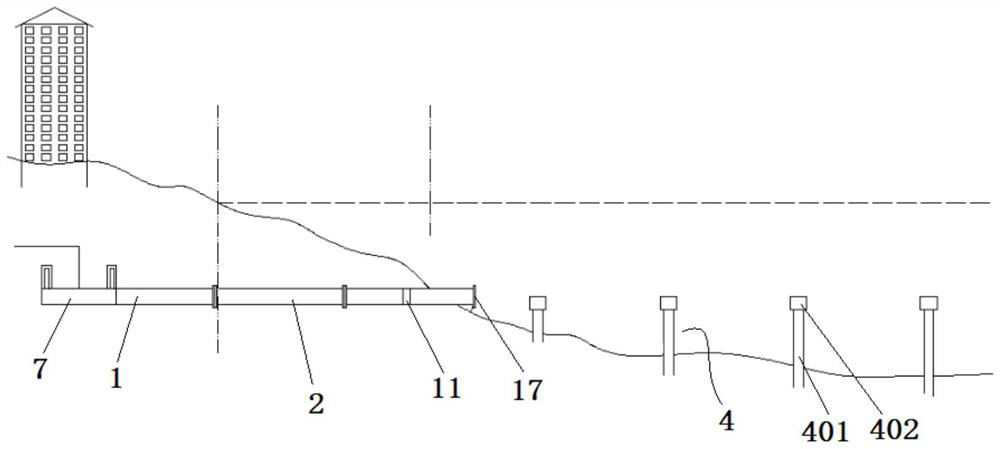

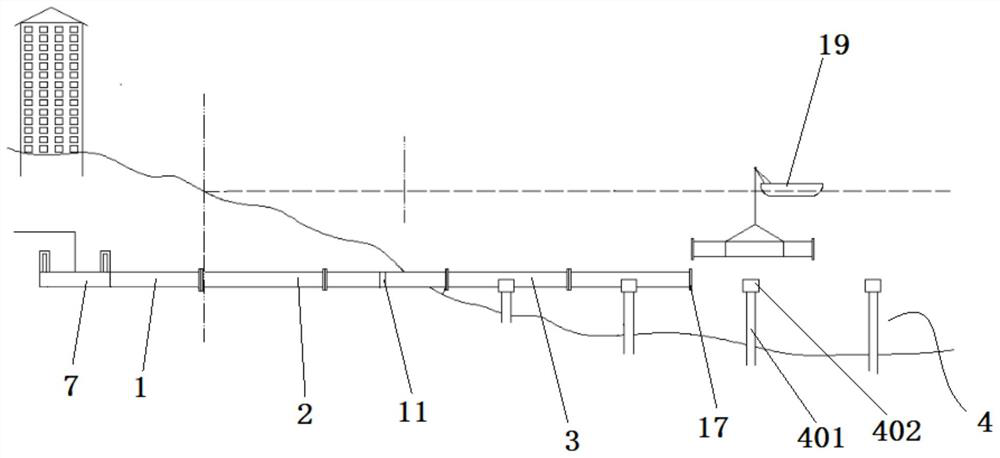

[0052] Such as Figure 1-Figure 6 As shown, the present embodiment provides a subsea vacuum pipeline test line that can be extended as an application line, including a vacuum pipeline 1 in the land section, a vacuum pipeline 2 in the near-shore subsea buried section, and a vacuum pipeline 3 in the elevated section of the seabed, which are arranged in sequence, and A subsea pipe pier 4 for supporting the vacuum pipeline 3 of the subsea elevated section;

[0053] The vacuum pipeline 2 of the offshore seabed buried section refers to the pipeline between the coastline and the water entry point where the vacuum pipeline buried underground enters the sea from the seabed, and this section belongs to the sea area;

[0054] The end of the vacuum pipeline 3 of the elevated section of the seabed is provided with an inner removal head 5 and an extension joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com