Method for extracting and separating stevioside from stevia rebaudiana by using deep eutectic solvents (DES)

A technology of low eutectic solvent and stevia is applied in the preparation of low eutectic solvent and the field of extracting stevia to achieve the effect of shortening the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

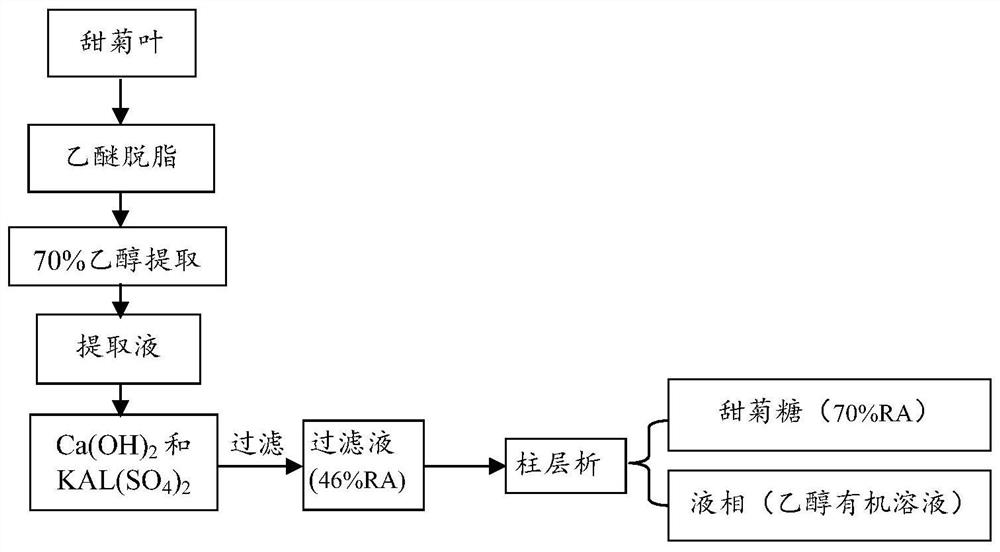

Problems solved by technology

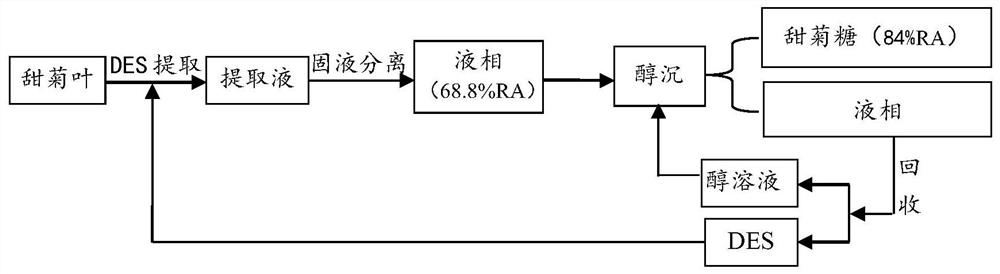

Method used

Image

Examples

Embodiment 1D

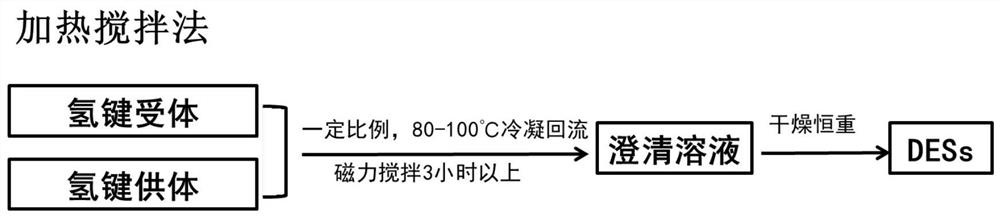

[0023] Example 1 DES synthesis (note: this embodiment only uses hydrogen bond acceptor [choline chloride], hydrogen bond donor [ethylene glycol] as reactants, and the rest of the DES synthesis conditions are exactly the same as this example, only the product differences in the hydrogen bond donors in the structure.)

[0024] Add an appropriate amount of choline chloride and ethylene glycol into a one-necked flask for later use, weigh and prepare a mixture of choline chloride: ethylene glycol = 1:2 (molar ratio) for later use; the mixture is stirred at 80°C After 4 hours, a colorless transparent liquid, ie a deep eutectic solvent (DES), was obtained. Store the DES in an environment lower than room temperature for use, and the moisture in it should be within 4%.

Embodiment 2

[0025] Embodiment 2 ethylene glycol DESs are used to extract stevioside

[0026] After the stevia was washed, it was naturally dried and crushed through a 200-mesh sieve. Take 5 grams of stevia and add 20% water content of DES aqueous solution (DES: water = 1:20) g / mL, put it into a 250mL single-necked flask, and put it in a 250mL single-necked flask. Carry out extraction experiment, solid-liquid ratio 1:20 (g / mL), extraction time 180min, after filtering and separating solid-liquid phase, obtain the extract containing stevioside (64.5% RA); Further separation adopts 80% ethanol to carry out alcohol Separation by precipitation to obtain higher content stevioside (81.2% RA), the extraction rate of stevioside per DES is 182mg / g.

Embodiment 3~11D

[0027] Embodiment 3~11DES is used for extracting other embodiments of stevioside

[0028] Examples 7-15 of DES applied to extract stevioside under other different conditions are shown in the table below. The extraction conditions not mentioned in the table are the same as in Example 2.

[0029]

[0030]

[0031] In summary, the present invention provides a preparation method of a low eutectic solvent and its selective adsorption on stevioside. This method uses DES to extract stevioside for the first time, and establishes a new method for selective adsorption and separation of DES.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com